5 proportional - integral block, Figure 6.16.3.3: pi block description – GE Industrial Solutions DV-300 DC Drive Users Manual User Manual

Page 271

DV-300 Adjustable Speed Drives

——— FUNCTION DESCRIPTION ———

6

143

Connection to a load cell with full range + 10V.

The output of the load cell can be connected to one of the drive analog inputs. Normally the analog input 1

(terminals 1 and 2) should be used because of the filter provided.

The input choosen for the connection must be programmed in the menu I/O CONFIG as PID feed - back. Its

value can be read in the PID feed - back parameter of the PID REFERENCE submenu.

The tension setting can be sent, with value 0...-10V, to one of the remaining programmable analog inputs in the

I/O CONFIG menu as PID offset 0.

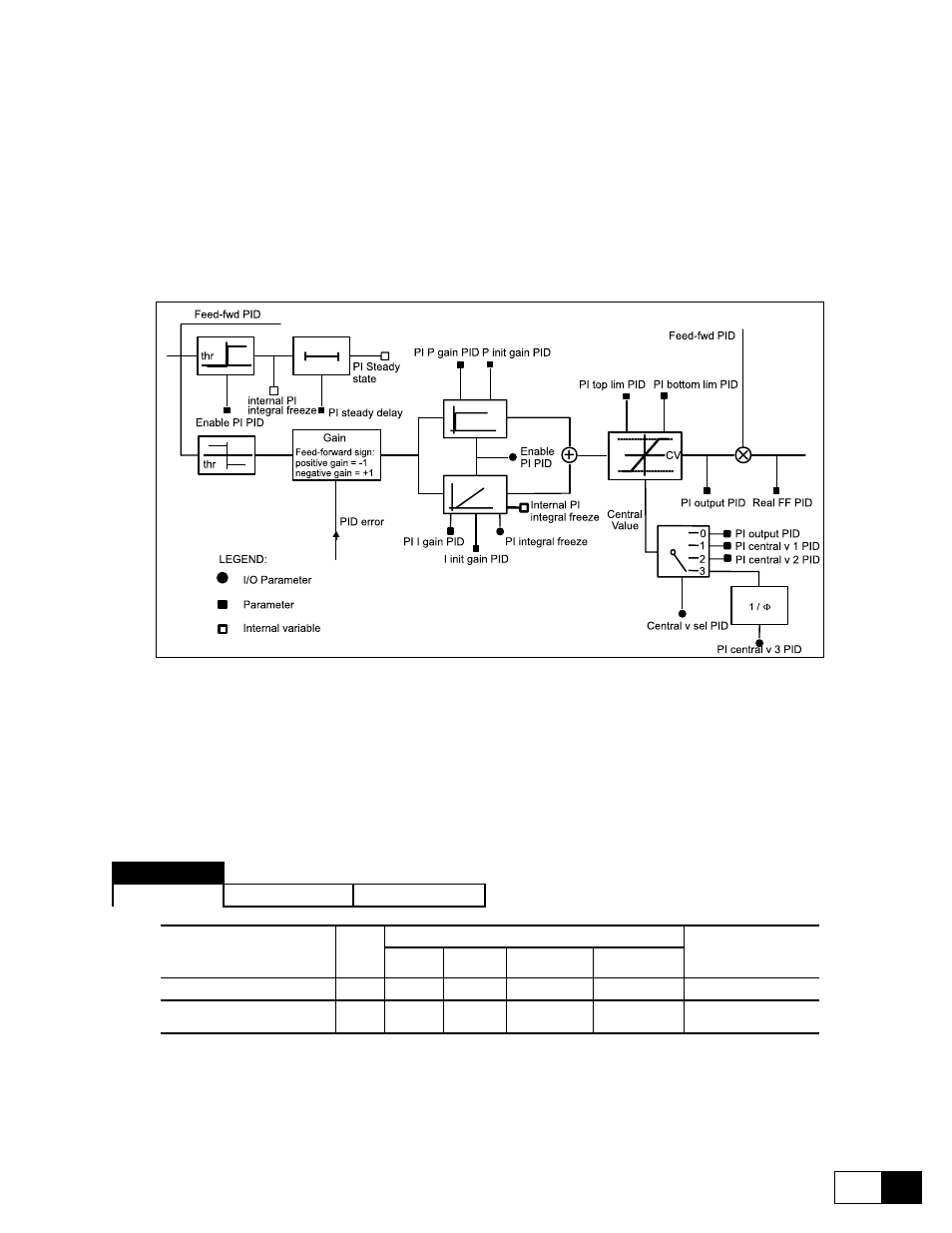

6.16.3.5 proportional - integral block

Figure 6.16.3.3: PI block description

The PI block receives its input from the PID error parameter, which represents the error that must be corrected

by the regulator. The PI block carries on a proportional-integral regulation, its output PI output PID after having

been appropriately adapted, according to the system which it has to control, it will be used as multiplier factor of

the feed-forward (Feed-fwd PID) obtaining the correct value of the speed reference for the drive (Real FF PID).

The PI block will be enabled setting Enable PI PID = Enable. If Enable PI PID has been programmed on a

digital input, this must be set to a high logic level (+2V.

PID

[769]

Enable PI PID

Parameter description

No.

Value

Standard

Configuration

min

max

Factory

American

Factory

European

Menu

Enable PI PID

Enabled (1) / Disabled (0)

769

0

1

Disable

Disable

*

* This function can be set on a digital programmable input.

Enable PI PID

Enabled

Enable of the proportional-integral block

Disabled

Disabling of the proportional-integral blc.