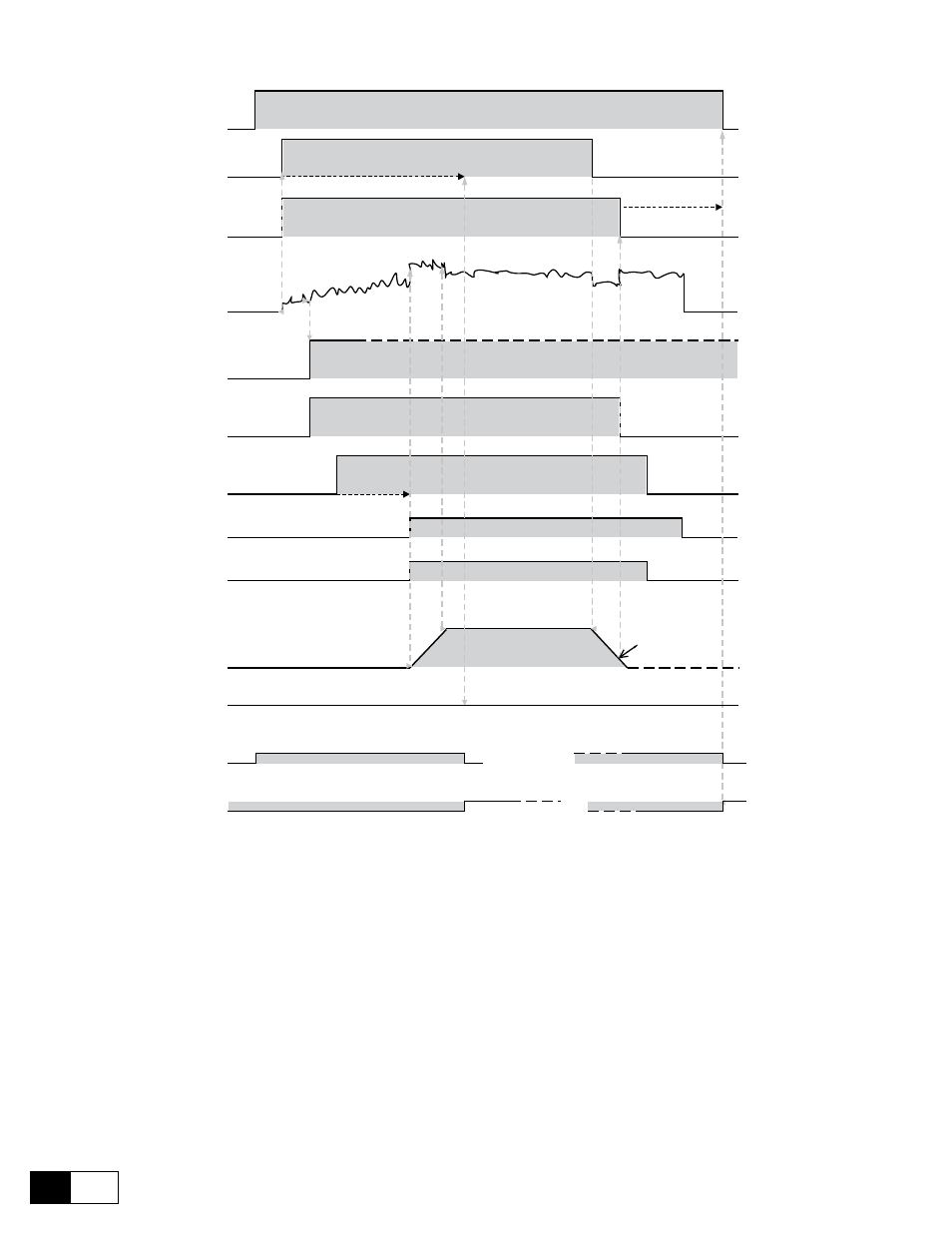

Figure 6.14.8.1: diagram of control – GE Industrial Solutions DV-300 DC Drive Users Manual User Manual

Page 252

GEI-100332Ga

——— FUNCTION DESCRIPTION ———

6

124

RUN

START

Torque front monitoring time

T = 1 sec

Brake drop

out speed

detection

Induced

current

Brake

release

current

detection

Brake

switch

command

Brake

switch

feedback

Actuator delay

time

Actual

opening

of brake

pads

Ramp

validation

Speed

feedback

Brake drop out threshold

Switch

delayed

feedback

Inverter

locking

Engaging fault

Mechanical

brake

fault

Engaging fault

Figure 6.14.8.1: Diagram of control

Diagram of control

Functional diagram with minimal use of inputs and outputs. Specific assignments of this diagram:

DI1:

Fwd sign Ascending, conventionally “Forward”

DI2 :

Rev sign Descending, conventionally “Reverse”

DI3:

Brake fbk Brake contactor feedback

Relay 2: Brake command KM10 contactor command

With reference to the previous graph, a brake alarm condition occurs if:

- when the brake is released, following the Enable and Start commands, the current is not adequate to support

the load (indicated by the Torque proving parameter and signalled by the Brake command digital output)

within less than the Torque delay time; or, when the current is adequate, the brake released confirmation

input (Brake fbk) is not received, again within the Torque delay time.

- when the brake is closed, once the Closing speed (signalled by the Brake command digital output) has been

reached, the input signal (Brake fbk) is not sent within less than 1 second.