2 terminal assignment, Table 4.7.2.3: xs1 9-pole connector – GE Industrial Solutions DV-300 DC Drive Users Manual User Manual

Page 61

DV-300 Adjustable Speed Drives

——— WIRING PROCEDURES ———

4

17

4.7.2 Terminal Assignment

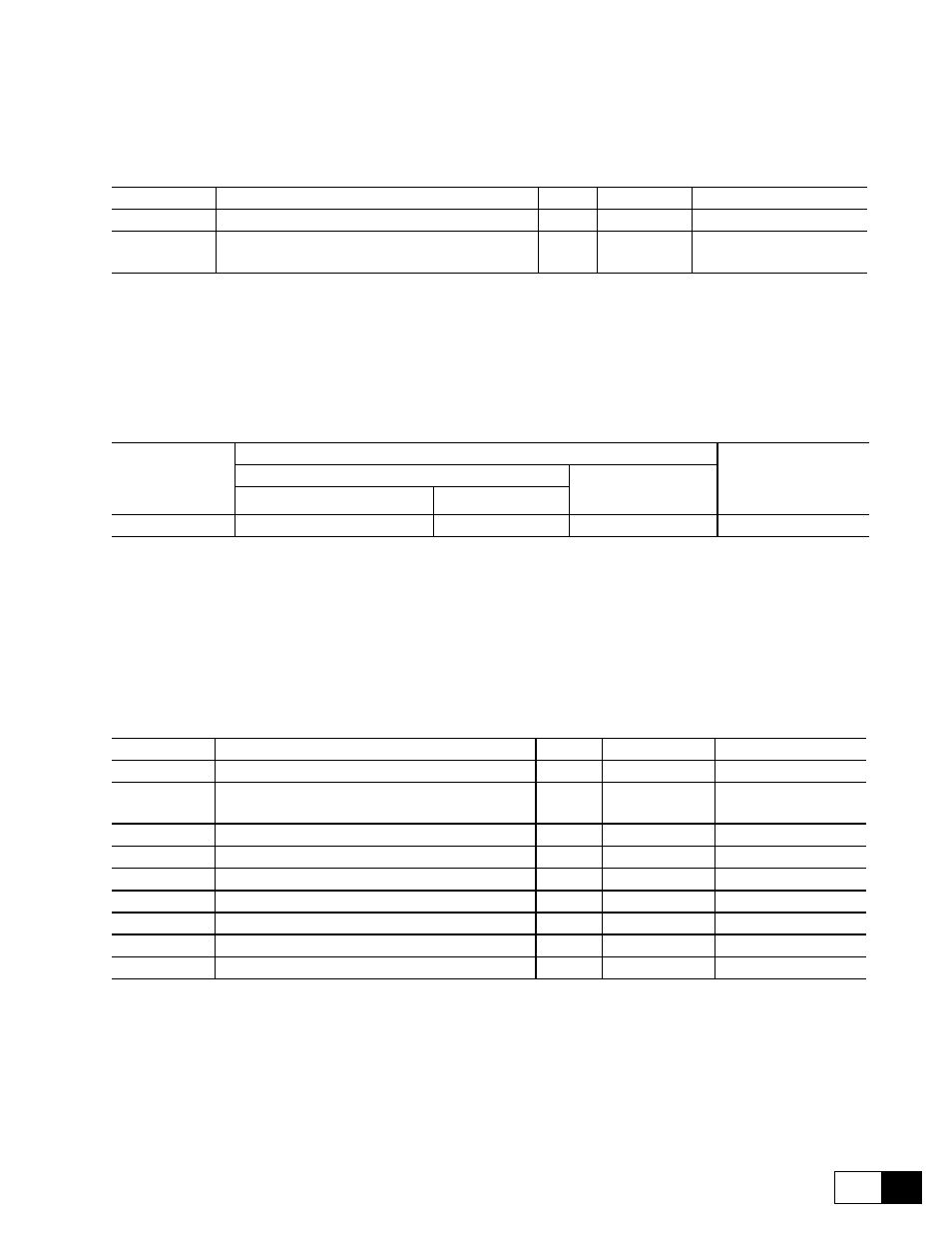

Table 4.7.2.1: Terminal assignment (Terminals 0Venc and +Venc)

Designation

Function

I/O

max volt.

max curr.

0Venc

0 V supply to the encoder

I

-

-

+Venc

+15 ... 24 V supply to the encoder (S1, S2, S3 open)

+5V supply to the encoder (S1, S2, S3 closed)

I

+24V

depending on encoder data

GD0260g

I = Input O = Output

Table 4.7.2.2: Permissible cable cross section on the terminals of option card 6KDV300DES

Terminals

Max cable connection section

Tightening

torque

[Nm]

[mm

2

]

AWG

flexible

multi-core

0 Venc and +Venc

0.14 ... 1.5

0.14 ... 1.5

28 ... 14

0.5

GD0270

The use of a 3 x 0.1 x 0.02 inches (75 x 2.5 x 0.4 mm) flat screwdriver is recommended. Strip the ends of the

cables to a length of 0.26 inch (6.5 mm). Only one unprepared wire (without ferrite) should be connected to

each terminal.

Table 4.7.2.3: XS1 9-pole connector

Designation

Function

I/O

max volt.

max curr.

PIN 1

Channel B-

I

+24V

10.9mA

PIN 2

Supply voltage for the encoder (the allowed level

depends on the jumper position, see chapter 4.7.1

+24V

depending on ext. power

supply unit

PIN 3

Channel C+ (zero pulse)

I/O

+24V

10.9mA

PIN 4

Channel C- (zero pulse)

+24V

10.9mA

PIN 5

Channel A+

I/O

+24V

10.9mA

PIN 6

Channel A-

+24V

10.9mA

PIN 7

Reference point for supply voltage

I/O

-

-

PIN 8

Channel B+

+24V

10.9mA

PIN 9

not connected

I/O

-

-

GD0280g

I = Input O = Output