11 program control related settings, Program control related settings -41 – Yokogawa Data Acquisition with PID Control CX2000 User Manual

Page 53

1-41

IM 04L31A01-01E

Explanation of Functions

3

2

1

4

5

6

7

8

9

10

11

12

13

14

1.11 Program Control Related Settings

Selecting the PID Selection Method

When program control is turned ON, select segment PID method (zone PID selection

OFF) or zone PID method.

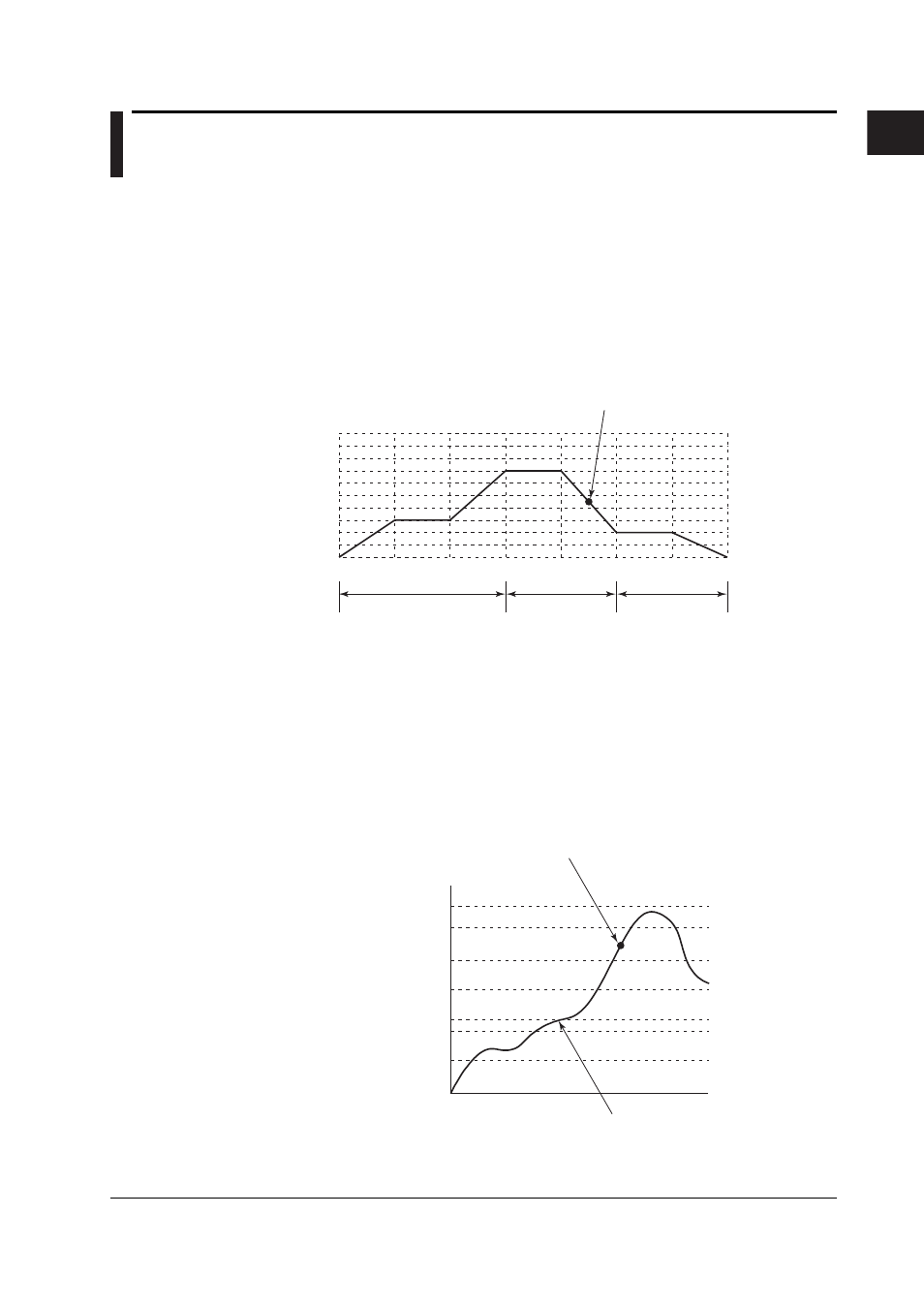

• Segment PID method

Segment PID method is a function in which the PID setpoint is switched for each

segment according to the program pattern setting during program operation.

Therefore, this method is suitable for control in which the PID constant is changed

during ramp-up and ramp-down in the same PV region.

Process

value

No.2PID

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

No.1PID

No.3PID

1000.0

500.0

0.0

If the current operation is

at the 5th segment, the

PID constant of No. 1 is

used.

• Zone PID method

Zone PID method is a function in which the PID setpoint is automatically switched

according to the PV. Therefore, the same PID constant is used in the same PV

region regardless of the ramp-up and ramp-down program operation. This method is

used on equipment such as reactors in which the chemical reaction gain varies

depending on the temperature.

As shown in the following figure, the measurement span can be divided into up to 7

zones using reference points 1 to 6. An optimum PID constant can be assigned to

each zone. Therefore, even if the PV changes and crosses between the zones, the

output is controlled automatically using the PID constant that is assigned to each zone.

No.1PID

Minimum value of PV span

Maximum value of PV span

Reference point 1

Reference point 2

Reference point 3

Reference point 4

Reference point 5

Reference point 6

No.2PID

No.3PID

No.4PID

No.5PID

No.6PID

No.7PID

Change in the process value (PV)

If the current process value (PV) here,

control using the PID constant of No. 6.