Program control (optional function) – Yokogawa Data Acquisition with PID Control CX2000 User Manual

Page 22

1-10

IM 04L31A01-01E

Program Control (Optional Function)

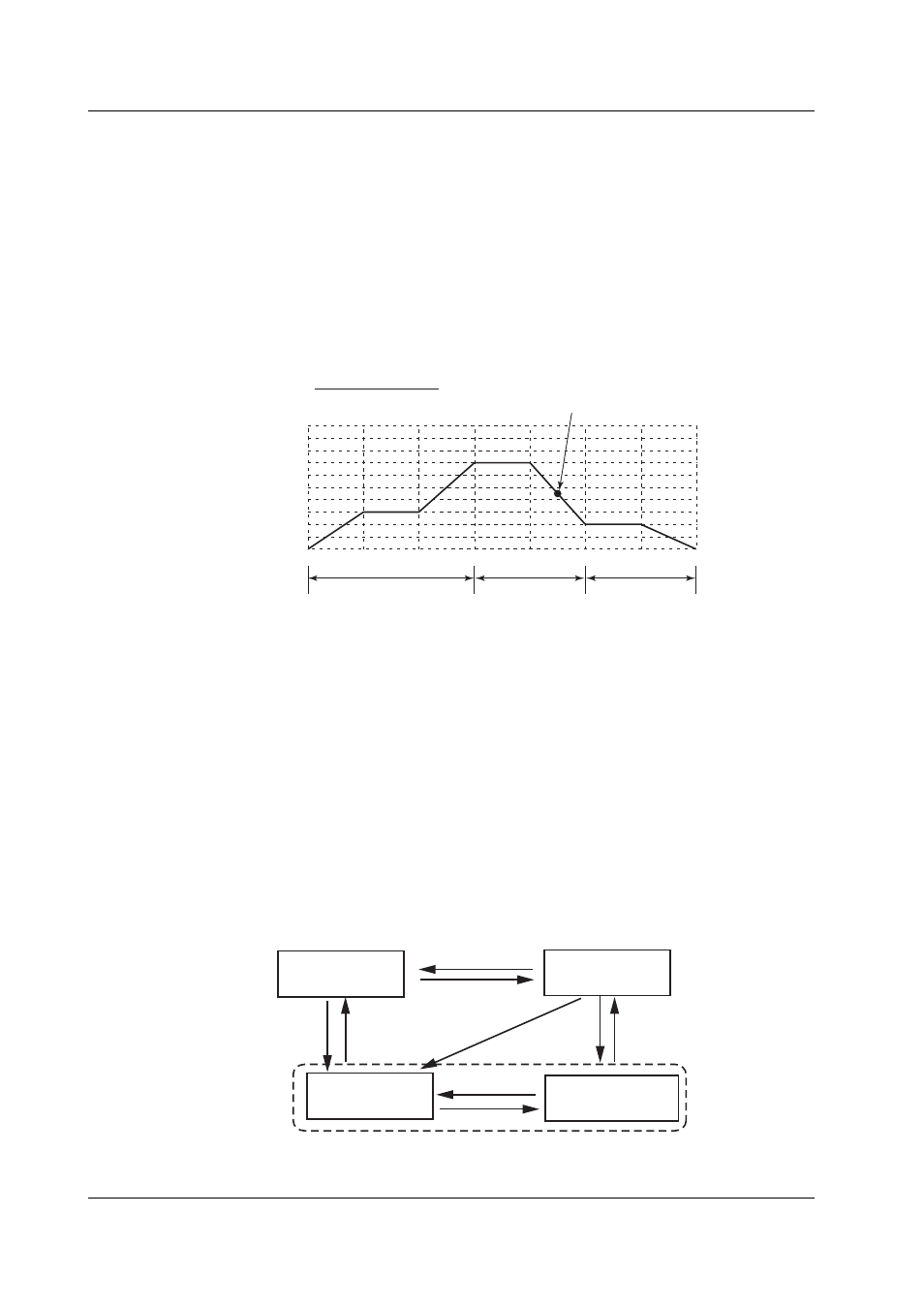

This function is used to ramp-up or ramp-down the SP according to a program pattern. You

can set multiple program patterns (up to 4 on the /PG1 option and up to 30 on the PG/2 option)

and switch among them according to the operating condition. A program pattern consists of

multiple program segments. With style number S3 or later, you can execute a program pattern

while a separate program pattern is executing as long as the operating loops do not overlap.

There are two methods in selecting the PID constant in program control. One is the

“segment PID method” in which the PID constant is switched every segment according to

the program pattern setting; the other is the “zone PID method” in which the PID

constant is automatically switched according to the PV. The “segment PID method” is

used when a different PID constant is required in the same PV region when the

temperature is rising and when the temperature is falling.

No.2 PID

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

No.1 PID

No.3 PID

1000.0

500.0

0.0

The PID constant of PID No. 1

is used in the 5th segment (SEG5).

Segment PID method

PV

Setting the Operation for Program Control

Settings include the number of repetitions of the program pattern (repeat function), delay

function (wait function) for the case when the PV cannot follow up the SP, and alarm output/

event output assignments (contact output can be assigned) according to the program progression.

Operation Mode during Program Control

The following 4 types of operation modes are available.

• Program operation mode

Condition in which control is carried out according to the program pattern.

• Hold operation mode

Condition in which the change in the SP according to the program pattern is forcibily

paused through key operation or other factors.

• Reset mode

Condition in which program operation of all loops is stopped. All event outputs are

cleared (off).

• Local operation mode

If you switch to local operation mode even during program control, fixed-operation is

perfomed acording to the SP set locally.

Reset mode

Local operation

mode

Program operation

mode

Hold operation mode

During program control

HOLD

Release HOLD

PRG RUN

LOC or program

LOCAL end

RUN

RESET or

all loop STOP

PRG RUN

RESET, program end,

or all loop STOP

PRG

Since the remote input cannot be used for the SP during program control, there is no

remote/local switching operation.

1.2 Control Function Overview