Yokogawa Data Acquisition with PID Control CX2000 User Manual

Page 23

1-11

IM 04L31A01-01E

Explanation of Functions

3

2

1

4

5

6

7

8

9

10

11

12

13

14

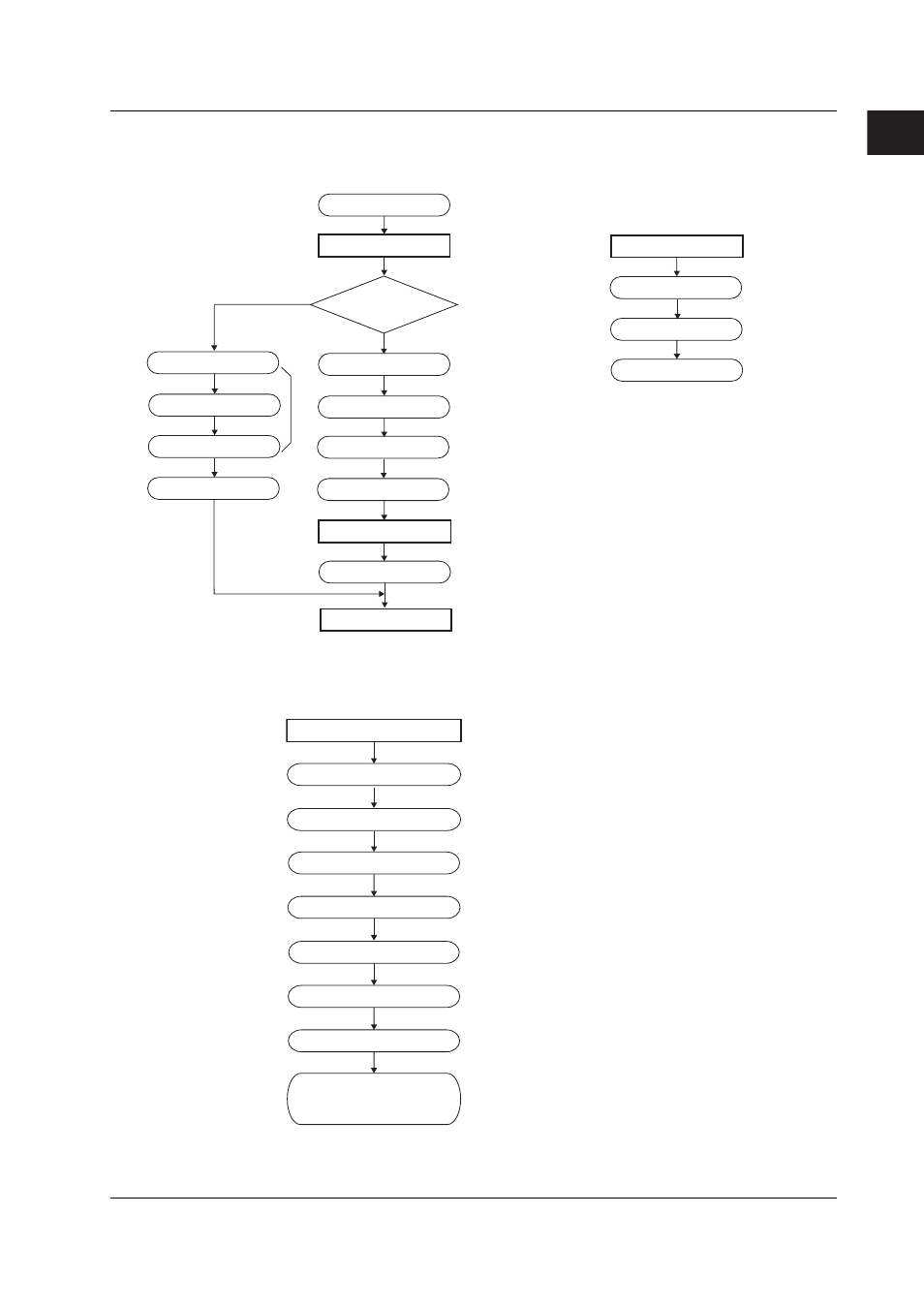

Flow of Setup Procedure

Below is a standard flow of setup procedure in executing control for the first time using

auto operation.

Basic settings

Power ON

PID control

ON/OFF control

Set SP

Adjust control

Operating condition

PID control or

ON/OFF control?

*

Start actual operation

Set PID parameters

Set SP

Start a test run

→ Section 1.6

→ Section 1.7

Set relay hysteresis

• Auto

tuning

• Manual tuning → Section 1.12

• Control output suppression → Section 1.8

• Other

adjustments

(Parameters that cannot be changed

during operation → section 6.1)

→ Section 1.3

Basic settings

Contact input/output

related settings

Basic control settings

Set alarm-related

parameters

→ Section 1.4

→ Section 1.5

Basic settings include the following

parameters.

Set other control

parameters

PV input related settings

→ Section 1.10

*

Set in

"Control Output Type"

of basic control settings

Set alarm-related

parameters

Section 1.9

When using program control, set the items that include “Program control: On” in “Basic

control settings” indicated above. Then, carry out the following settings in addition to

“Target setpoint/PID parameter settings.”

Settings for program control

Pattern initial setting

Wait action setting

Pattern start setting

Program pattern setting

Event setting

Event output setting

Repeat action setting

Pattern initial setting:

Set the pattern numbers, pattern off/on, number of

segments used, segment assignment method, edit

segment number, and Loop number.

Pattern start setting:

Set starting target setpoint and start code (operation

start condition).

Program pattern setting:

Set segment numbers, ramp/soak, final target setpoint,

segment time, ramp-rate-time unit, ramp-rate, segment

PID group numbers, operation at the time of segment

switching, wait operation type, and wait numbers.

Wait action setting:

Set wait zone off/on, wait zone settings, and timer.

Event setting:

Set event types, loop number/type/setpoint (only when

PV event is selected), time event ON/OFF, ON time/OFF

time (only when time event is selected) and hysteresis of

PV event.

Event output setting:

Set the event type, relay output ON/OFF, and relay

output number.

Repeat action setting:

Set the repeat function, number of repetitions, start

segment number, and end segment number.

Auto message printing/

program display position

setting

→ Section 1.11

1.2 Control Function Overview