Festo Контроллер позиционирования CPX-CMAX User Manual

Page 80

3. Drive functions

3−18

Festo P.BE−CPX−CMA X−CONTROL−EN en 0908NH

Position control

The Motion Complete (MC) signal indicates whether the last

started task has been ended. It is made up of several logical

conditions. See Tab. 3/5 and Fig. 3/4.

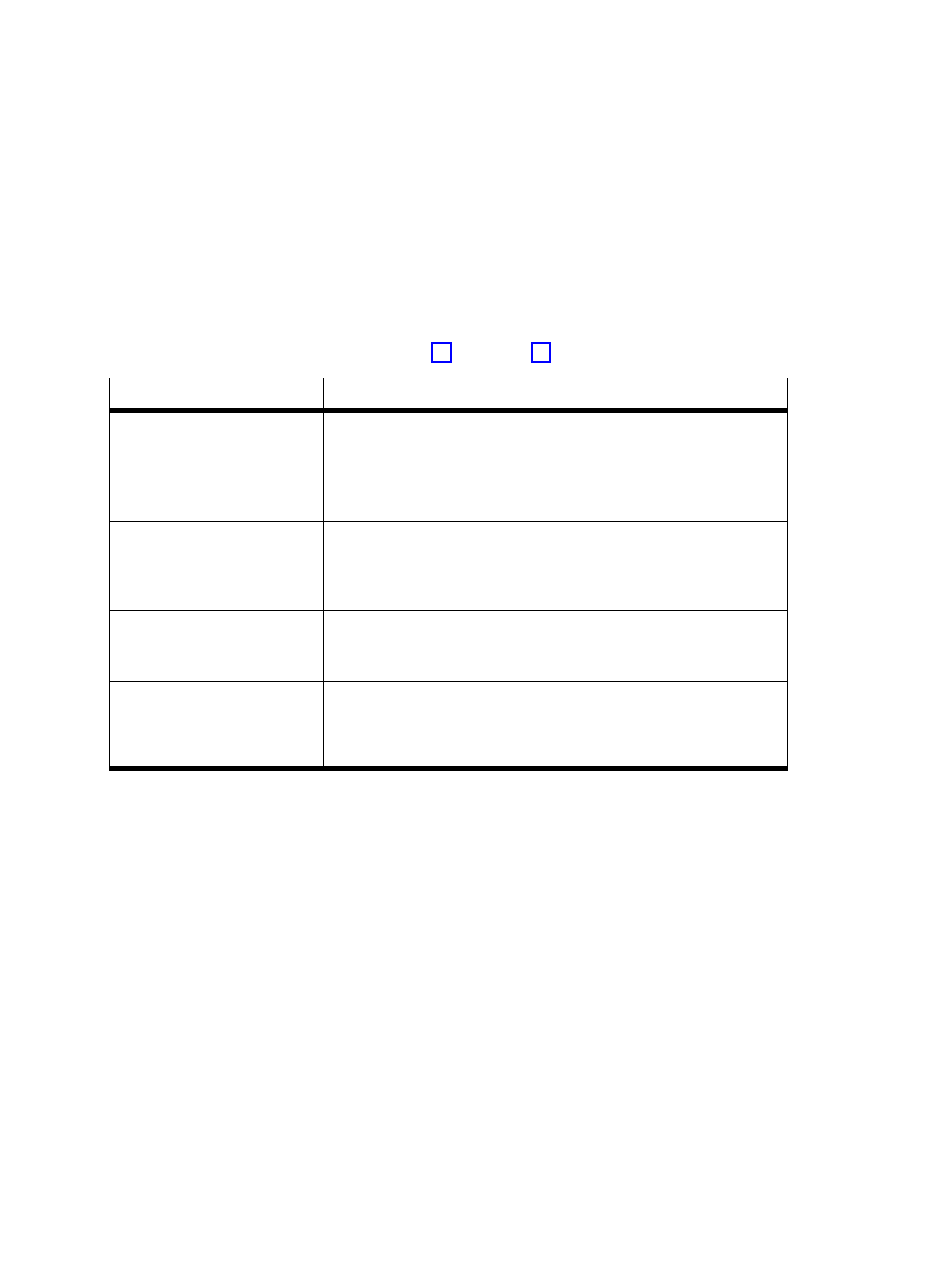

Condition

Description

Permanent entry in tolerance

window for position

The actual position reaches the tolerance window and does not

exit it again during the set monitoring time. The monitoring time

(PNU 1154) can be configured in expert mode with the FCT

(controller data −> position controller). The tolerance window

corresponds with the target position +/− the currently set tolerance.

Permanent entry in tolerance

window for speed

The actual speed reaches the speed tolerance window and does not

exit it again during the set monitoring time. The monitoring time is

the same as for the position (PNU 1154). The tolerance window is

equivalent to +/− 4 mm/s.

Starting timeout

(fault E31)

After starting the setpoint curve, the axis must have moved by at

least 11 mm within the timeout time (PNU 1153). Otherwise, the

CMAX signals a starting timeout.

Positioning timeout

(fault E30)

At the end of the setpoint curve, the position and speed conditions

must be met. If one of the two conditions is not met by the end of

the timeout time (PNU 1153), the CMAX signals a positioning timeĆ

out.

Tab. 3/5: Conditions for Motion Complete

For the quality class Fast stop", MC is set as soon as the

actual position has reached the tolerance window position.

The monitoring time is not waited and the speed condition is

not taken into consideration. That means that the axis might

still be moving when MC occurs. It is possible that the tolerĆ

ance could be exited again.

Due to the fast stop, the positioning time is shortened accordĆ

ingly (= time to MC). This is suitable for positions which do

not require high precision.