Procedure – Festo Контроллер позиционирования CPX-CMAX User Manual

Page 35

2. I/O data and sequence control

2−7

Festo P.BE−CPX−CMA X−CONTROL−EN en 0908NH

2.2

Structure of the cyclical I/O data in the operating modes

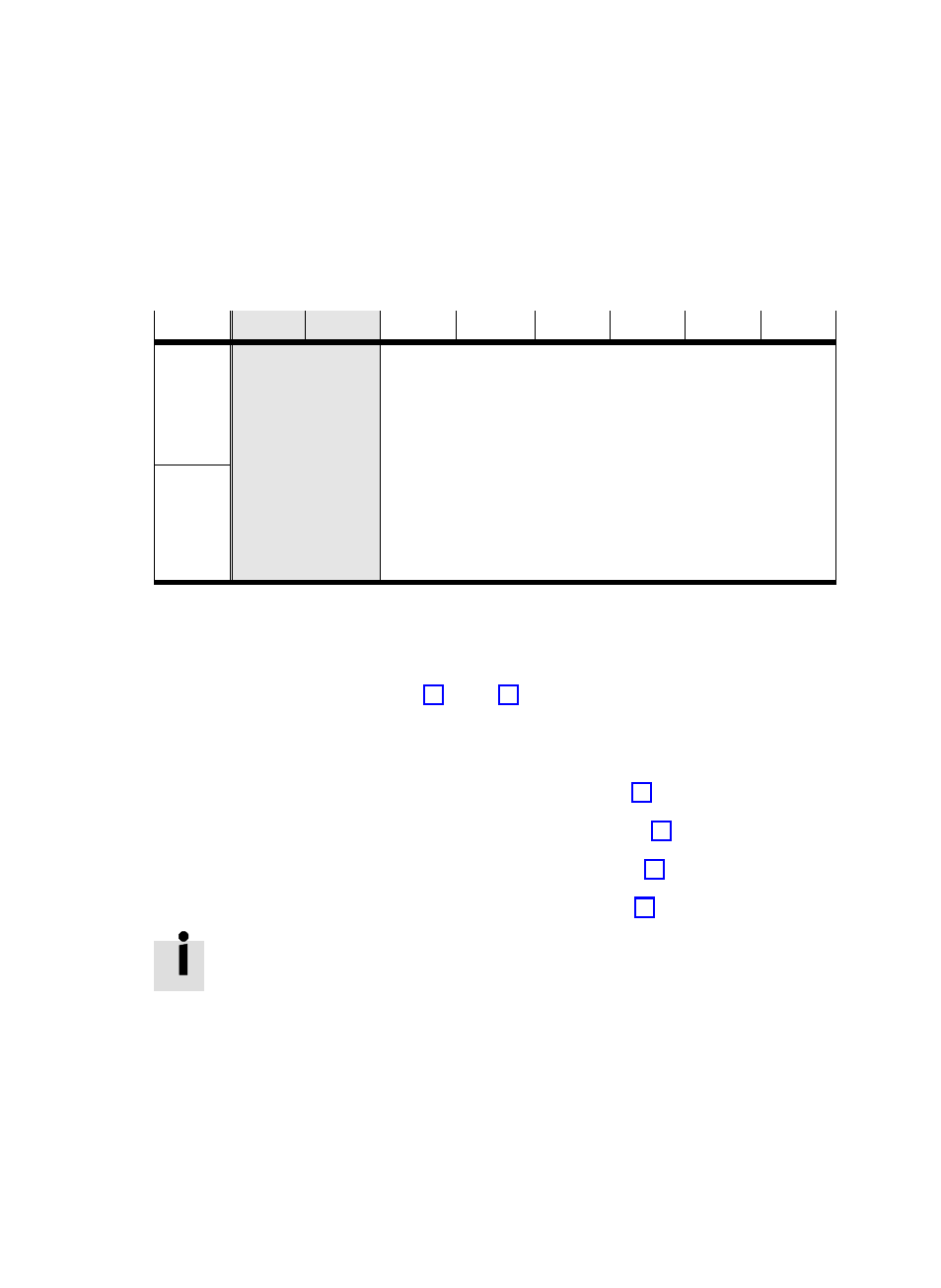

Data

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Output

data

Bytes 1 and 2 (fixed)

are retained in every

operating mode

(except byte 2 for

parametrisation).

They contain control

Bytes 3 to 8 depend on the selected operating mode (direct mode,

record select) and transmit further control and status bytes (e.g.

CDIR, SDIR,...), as well as setpoint and actual values:

Ĉ Record number or setpoint position in the output data

Ĉ Feedback of actual position and record number in the input data

Ĉ Additional operating mode− and control mode−dependent setĆ

Input

data

They contain control

and status bytes

(e.g. CCON,

SCON, ...) for enabĆ

ling the CMAX and

setting the operatĆ

ing modes

Additional operating mode− and control mode−dependent setĆ

point and actual values

Procedure

First define the operating mode in the CCON control byte. See

sections 2.2.1 and 2.2.2.

This results in the assignment of the other control and status

bytes:

ć

Record select mode, see section 2.2.3.

ć

Direct operating mode, see section 2.2.4.

ć

Commissioning mode, see section 2.2.5

ć

Parametrising mode, see section 2.2.6.

Recommendation: During operation, set the control bit

CCON.LOCK. This way, the PLC can ensure that the proĆ

grammed sequence cannot be disturbed by access with

the FCT.

Evaluate the status bit SCON.FCT_MMI, and take the missing

control access into consideration in the program sequence of

the PLC.