Festo Контроллер позиционирования CPX-CMAX User Manual

Page 146

4. Faults and diagnostics

4−10

Festo P.BE−CPX−CMA X−CONTROL−EN en 0908NH

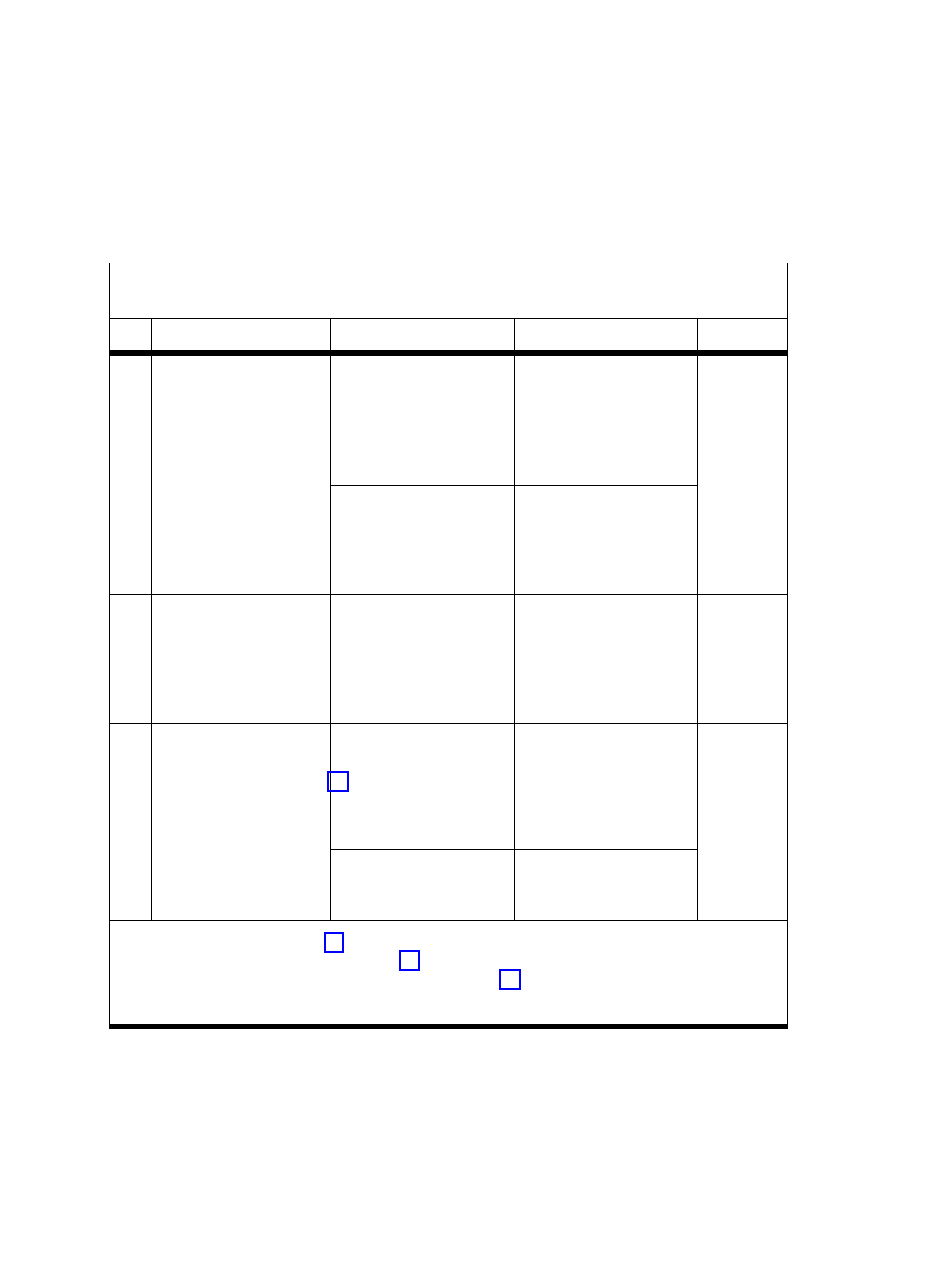

Fault group 0 ć configuration error

CPX error group 100 (CPX−MMI: [Configuration error] )

continued

No.

Message

Cause/description

Error handling

Type

1)

05

Project not loaded comĆ

pletely or block downĆ

load active

The controller cannot be

enabled because the

nominal configuration is

not yet complete.

(Configuration status

C00, C01 or C02).

·

Complete the nominal

configuration, e.g.

project download.

Level: F2

Reset: R

Info: ć

The controller cannot be

enabled because block

download is still active.

·

Terminate block downĆ

load. Check PLC proĆ

gram (parametrisaĆ

tion) and correct if

necessary.

08

Cylinder, valve or

sensor interface was

exchanged

2)

The serial number of a

component on the axis

string has changed:

Ĉ Drive (measuring

system).

Ĉ Valve.

1. Adopt serial number of

the component.

2. Run movement test

(recommendation).

3. Carry out identification

(recommendation).

Level: W

Reset: F

Info: x

09

Faulty parameter in the

project

Software end positions

inconsistent, see section

B.2.4.

·

Read diagnostics memĆ

ory, determine paraĆ

meter via additional inĆ

formation.

·

Check and correct softĆ

ware end positions.

Level: F2

Reset: N

Info: x

Invalid values concerning

axis parameters or hardĆ

ware configuration.

·

Check parameters and

correct.

1)

Level: fault level, see section 4.2.3

Reset: behaviour upon reset, see section 4.2.4

Info:

ć = no info; x = additional info, see FCT or section 4.3.3

2)

The movement test is reset to avoid tubing errors. The CMAX has C03 status. The movement test

should then be run once more.