9 working with dual processes, The workstation displays this screen – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 78

Configuring Axes

Chapter 3

3-14

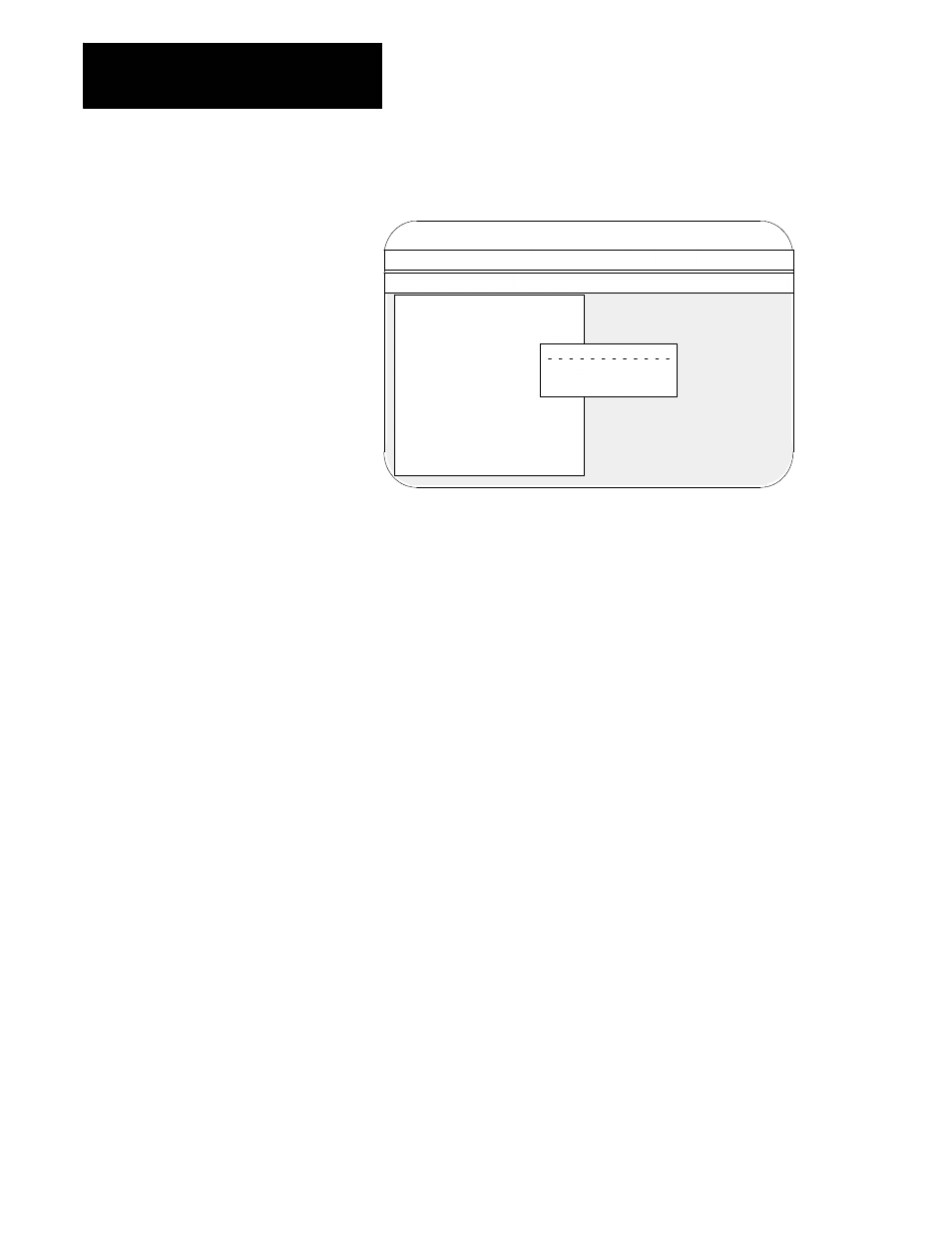

The workstation displays this screen:

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Type : Lathe

AXIS: X

P1:

Axis Parameters

Home Parameters

Zone/Overtravel Parameters

Servo Parameters

Jog Parameters

Feedrate Parameters

Acc/Dec Parameters

CSS Parameters

Spindle 1 Parameters

Spindle 2 Parameters

Spindle 3 Parameters

Axis Program Format

Letter Format

Plane Select

Page 1 of 3

File :

TEST

Control Type :

350

Lathe

(a)

Mill

(b)

3.

Select either Lathe or Mill for Lathe/Mill applications. Select either

Surface Grinder or Cylindrical grinder for Grinder applications. You

may also want to change your lathe type (lathe A, B, or C) or your

mill type (standard mill, or transfer line mill). Refer to the chapter on

Miscellaneous parameters.

The workstation records the selected control type and returns to the

main menu.

If you are using a Dual--Processing Control, you can control two processes.

Use the F5--Process key to select, and configure each process. Once you

select and configure each process, you can set the parameters for each

process. If the parameters for one process are similar to the other process,

you can copy the process and its parameters and configure it as the

second process.

3.9

Working with Dual

Processes