4 excess error – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 177

Servo Parameters

Chapter 7

7-31

Function

This parameter places an upper limit on following error for a servo. When

the magnitude of the following error exceeds the value entered here, the

control goes into E-Stop. The error message EXCESS FOLLOWING

ERROR appears on the message line of the control.

ATTENTION: This parameter plays a significant role in

machine safety, as it can prevent damage and injury resulting

from mechanical or electrical failure of a servo.

The smaller the value for this parameter, the sooner the control detects a

servo problem and goes into E-Stop. However, too small a value here

interferes with normal axis motion.

Important: To avoid a Warning: ”SERVO AMP FE LIMITS

CORRECTED”: Inposition Band < Gain Break Point < Feedrate

Suppression Point

£ Excess Error

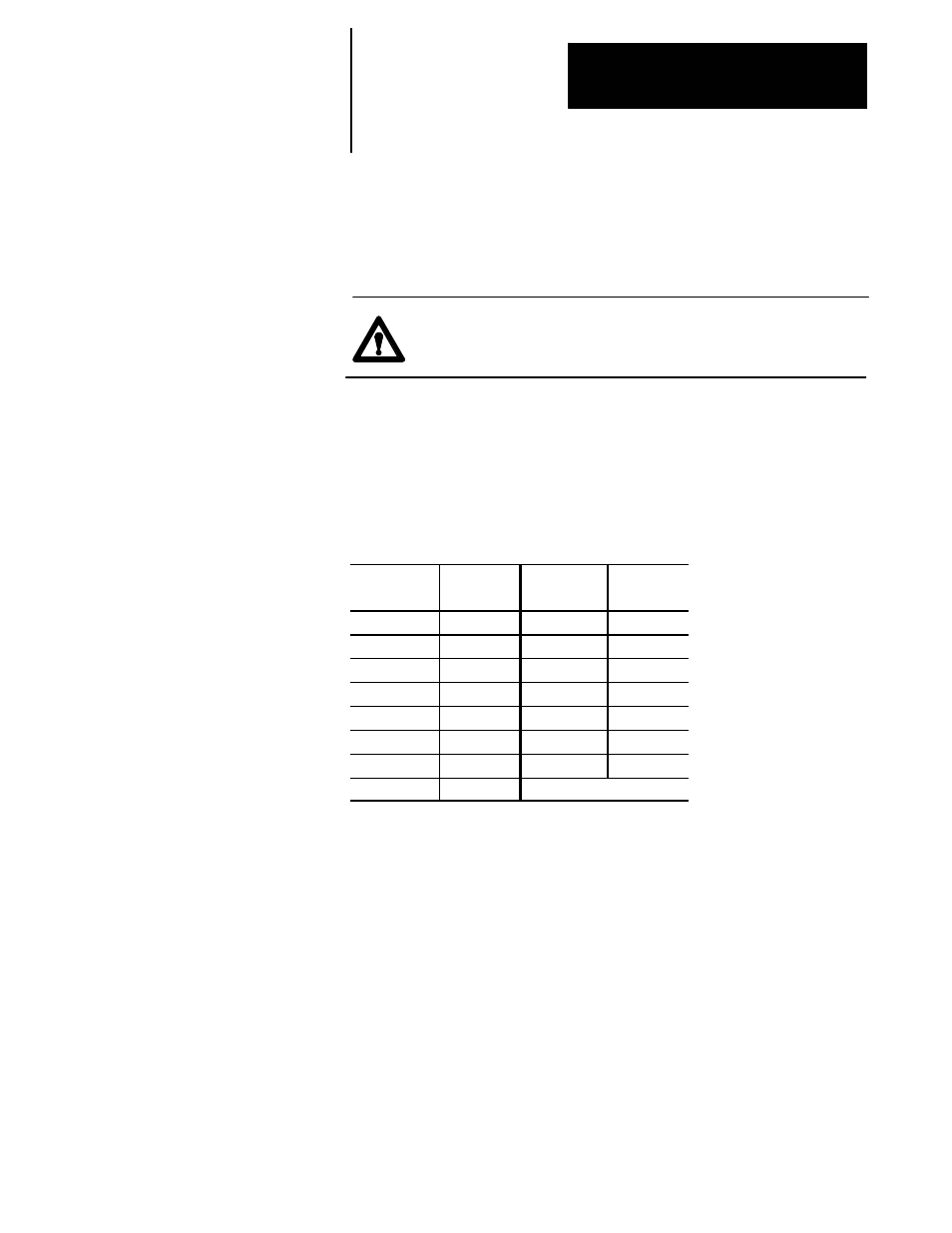

Axis

Parameter

Number

Axis

Parameter

Number

(1)

[1750]

(9)

[9750]

(2)

[2750]

(10)

[10750]

(3)

[3750]

(11)

[11750]

(4)

[4750]

(12)

[12750]

(5)

[5750]

(13)

[13750]

(6)

[6750]

(14)

[14750]

(7)

[7750]

(15)

[15750]

(8)

[8750]

Range

0 to 214.10000 mm or 0 to 8.42913 in. (linear axes)

0 to 1440.0000 degrees (closed--loop spindles)

0 to 214.00000 degrees (rotary axes)

Notes

This parameter must be set independently for each servo.

A typical value is 110% of the maximum following error expected during

operation of an axis. This can be determined by the following equation:

(maximum rapid speed) (1.1)

Min. Excess Error =

------------------------------------------

(Initial Gain) (1000) (Gain Break Ratio)

On closed--loop spindle applications, this parameter is only applied to the

servo while the spindle is orienting or tapping.

7.2.4

Excess Error