Spindle synchronization, 0 chapter overview, Chapter – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 383

Chapter

15

15-1

Spindle Synchronization

Use the spindle synchronization parameters to synchronize velocity or

position and velocity between two spindles with feedback using your

9/260, 9/290, or 9/440 control.

The feedback ratio between the two spindles must be a simple ratio with

either side no greater than 10 (e.g., 1:1 or 10:7). If either side of the ratio

exceeds 10 (e.g., 11:1 or 5:12), an error will occur.

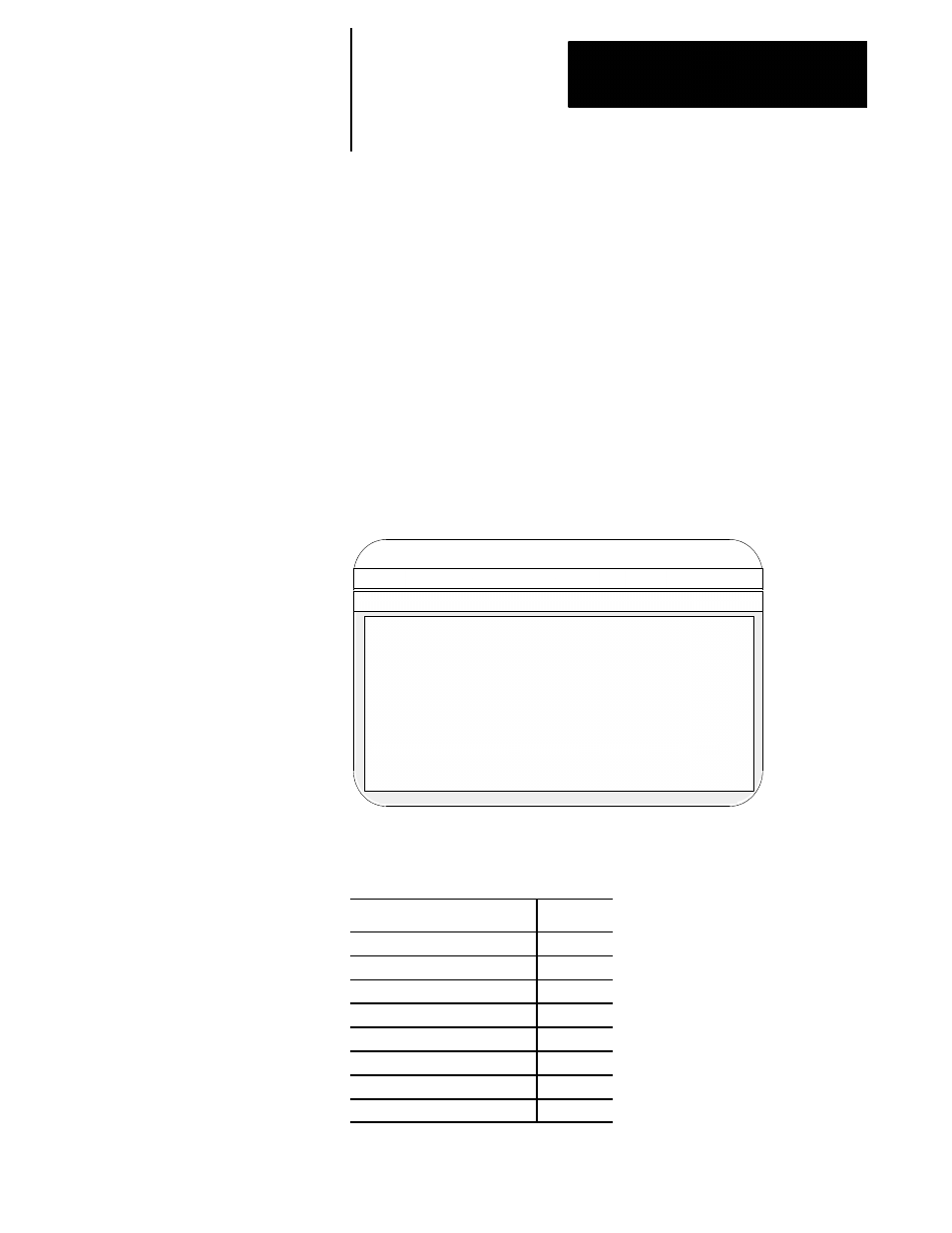

Select the “Spindle Synchronization” screen from the first page of the main

menu to access the synchronization parameters.

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

- Spindle Synchronization -

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Type : Lathe

AXIS: X

- Spindle

File :

TEST

Controlling Spindle

:

None

Follower Spindle

:

None

Follower Orientation

:

Normal

Synch Gain

:

0.000

Default Position Offset

:

0.000 degrees

Maximum Deviation

:

0.000 degrees

Seek Tolerance

:

0.000 degrees

Seek Timeout

:

0.00 seconds

This table lists the parameters that are necessary to configure spindle

synchronization:

Parameter:

Page:

Controlling Spindle

15-2

Follower Spindle

15-3

Follower Orientation

15-5

Synch Gain

15-6

Default Position Offset

15-7

Maximum Deviation

15-8

Seek Tolerance

15-8

Seek Timeout

15-9

15.0

Chapter Overview