Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 222

Servo Parameters

Chapter 7

7-76

When this program is executed with the position loop type set to “ZFE

Closed Loop” and feed forward set to 100%, changing the VE Integrator

Discharge Rate has noticeable results during the velocity transitions

(especially if a strip chart recorder is used). If the position loop type is set

to “Closed Loop,” the effects are more difficult to observe.

Continue increasing the value of the VE Integrator Discharge Rate,

executing this program after each change. The transitions and steady state

movements should remain smooth and stable. When the VE Integrator

Discharge Rate is set too high, velocity transitions are no longer smooth

(steady state conditions most likely are not affected).

Important: If the velocity transitions are not smooth with a value of one

set for the VE Integrator Discharge Rate, the initial settings for the

Velocity Proportional Gain and/or Velocity Integral Gain are most

likely incorrect.

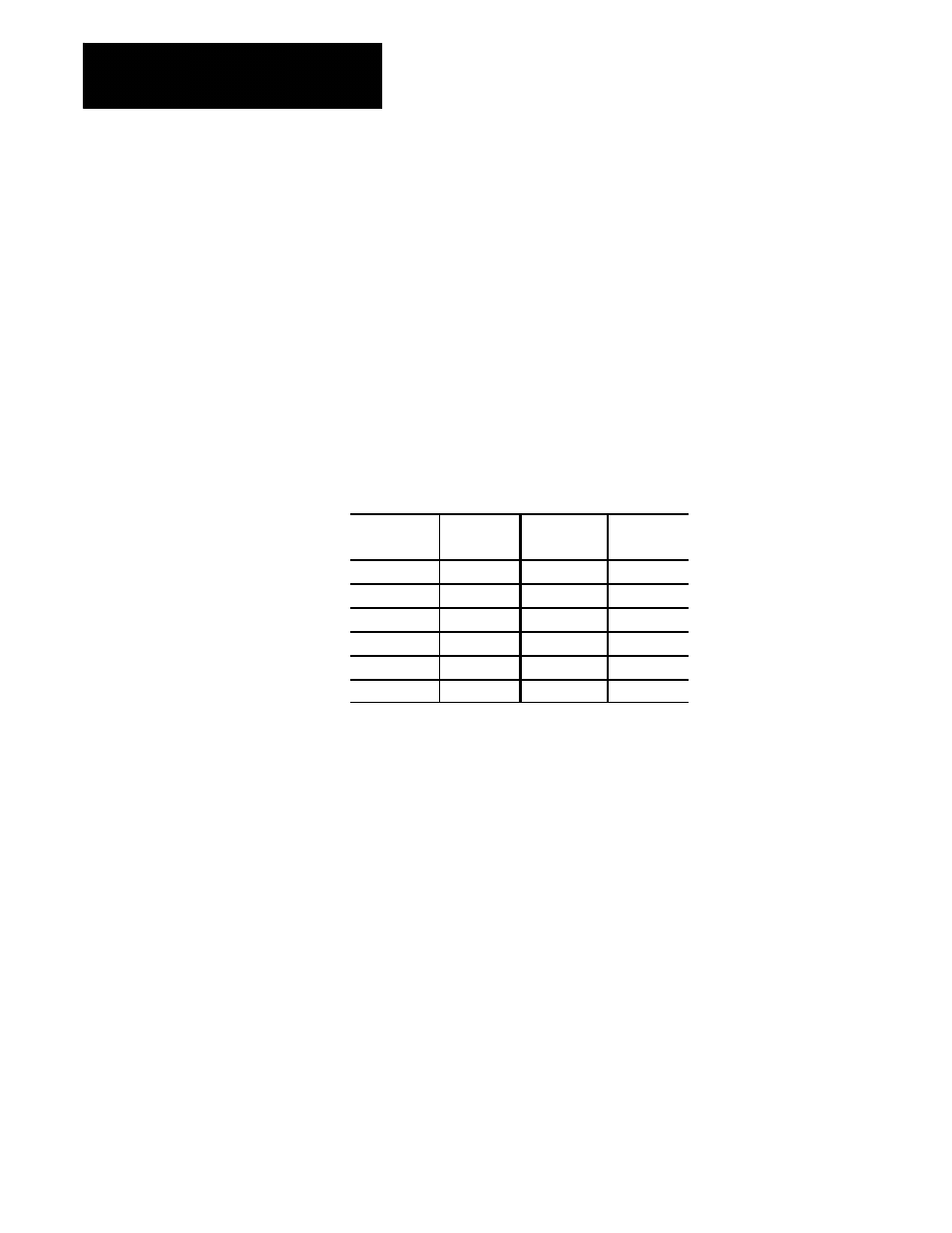

Axis

Parameter

Number

Axis

Parameter

Number

(1)

[1023]

(7)

[7023]

(2)

[2023]

(8)

[8023]

(3)

[3023]

(9)

[9023]

(4)

[4023]

(10)

[10023]

(5)

[5023]

(11)

[11023]

(6)

[6023]

(12)

[12023]

Range

1 to 8

Notes

The use of a strip chart recorder when adjusting this parameter is almost

essential. The “DAC monitor” feature provides an easy method for using a

strip chart recorder. This feature outputs various servo values such as

velocity feedback, following error, etc., to connector TB2 of the servo

module, connector TB3 of the 9/230 or either connector TB2 or TB3 of the

9/440. Refer to Appendix A for more information.

This parameter must be set independently for each servo.

This parameter must always be entered as an integer value.