9 position tolerance for skip 1 - 4 – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 483

Tool Offset Parameters

Chapter 22

22-11

Function

Use these parameters to determine the position tolerance for the four

different skip cycles called by the G37 codes. This position tolerance is

used to set a range

±

from the nominal end-point that is programmed in the

G37 block. The skip signal must be received by PAL when the tool is

within this position tolerance range for the control to modify the

offset tables.

If the skip signal is received before the tool enters the position tolerance

range, the remaining motion of the G37 block is aborted, and the control

continues on to the next block. If the skip signal is not received by the

time the tool exits the position tolerance range, the control continues on to

the next block. In either case, no modification of the tool offset table is

performed, and an error is generated though program execution is

not interrupted.

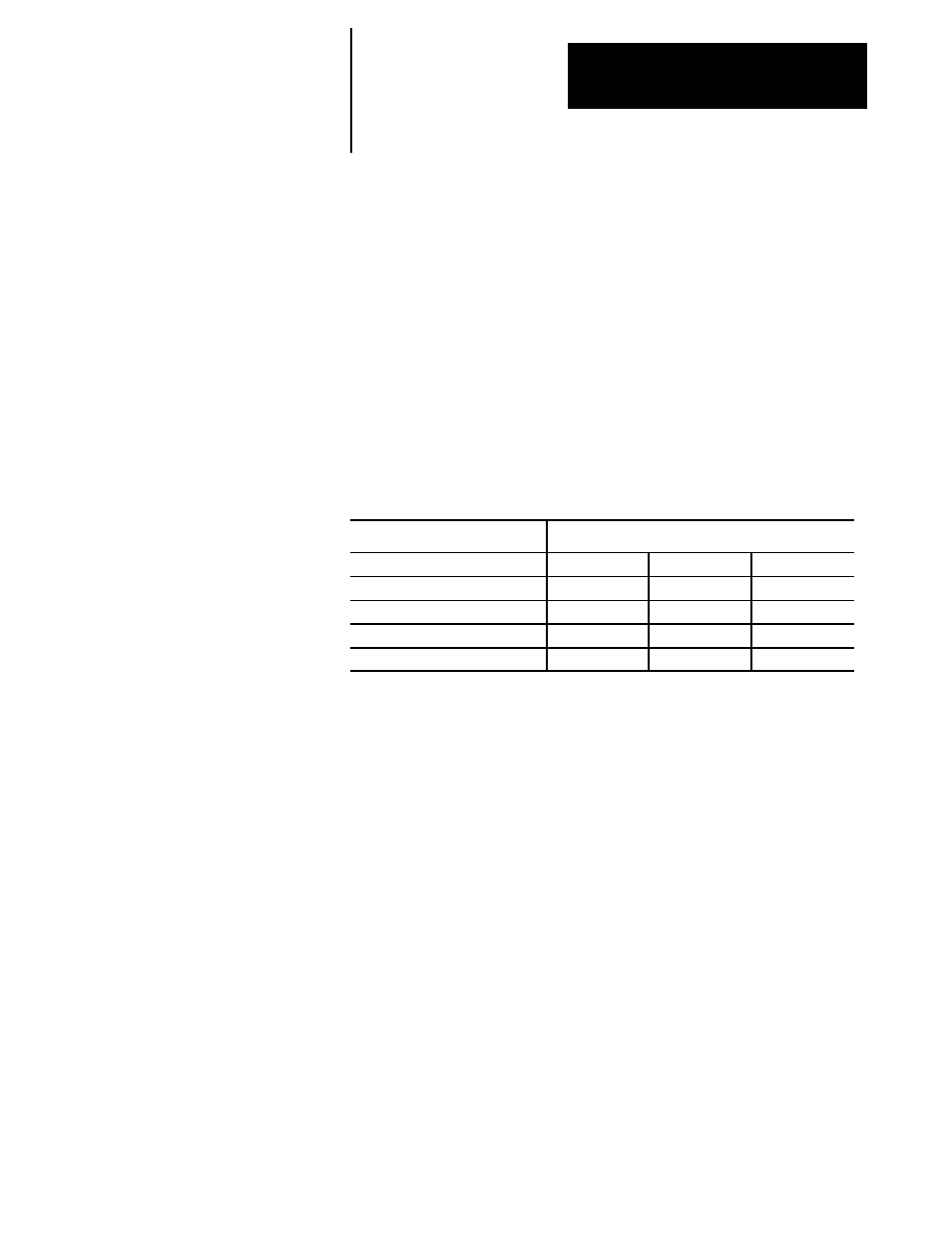

Parameter

Parameter Number

Single Process

Process 1

Process 2

Position tolerance for Skip 1

[206]

[20206]

[21206]

Position tolerance for Skip 2

[207]

[20207]

[21207]

Position tolerance for Skip 3

[208]

[20208]

[21208]

Position tolerance for Skip 4

[209]

[20209]

[21209]

Range

0.00000 to 100.00000 mm

or

0.00000 to 3.93701 inch

Notes

These are global parameters; the value set here applies to all axes.

For Dual Processing controls, this is a per process parameter. The value set

in the parameters applies to all of the axes assigned to that process.

22.9

Position Tolerance For Skip

1 - 4