Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 130

Zone/Overtravel Parameters

Chapter 6

6-4

The size and location of this zone are determined in AMP or on the

control.

Zone 3 defines either an interior zone (tool must stay within zone

boundaries) or an exterior zone (tool must stay outside of the zone

boundaries). This zone is enabled or disabled by part program commands.

The size and location of this zone is determined in AMP, on the control, or

through programming commands.

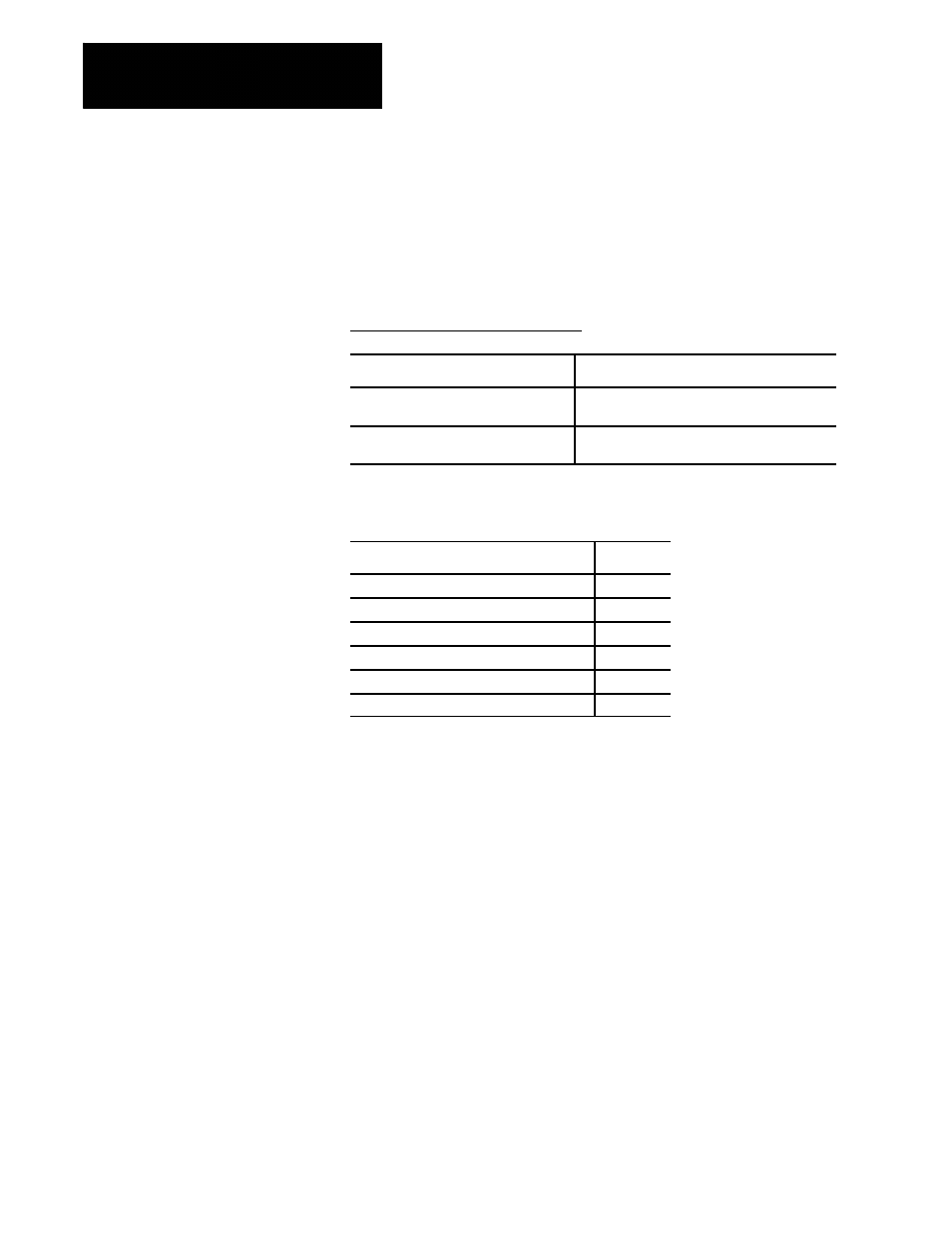

Programmable zones can check:

where:

each axis independently

the tool cannot move past the coordinate value

set for an axis

axes simultaneously

the coordinate values set for each axis define an

area that the tool may not move into or out of

These subsections offer a discussion on the parameters that are used for the

programmable zones.

Subsection:

Page:

Programmable Zone Group Axis

6-5

Number of Limit 2, 3 Groups

6-8

Limit 2 Max Value

6-9

Limit 2 Min Value

6-10

Limit 3 Max Value

6-11

Limit 3 Min Value

6-12

On dual processing controls that have a shared axis, zone values are per

axis, not per process. You can only enter one set of min and max values

for each zone for a shared axis. These values are used in the zone in both

processes.

On angled wheel grinders that have a virtual axis, the values you enter here

are applied to the real wheel axis. You can not enter values in AMP for the

virtual axis. When the control enters angled wheel mode (G16.3 or G16.4)

the control performs a calculation on the W axis values based on the

current angle of the wheel axis. This calculated value is applied to the

virtual X axis to create the zone in angled wheel mode. The calculation

performed to get the virtual axis values is:

X zone value = (COS A)(W zone value)

Where:

A = wheel axis angle

W = min or max W axis zone value