6 friction parameters – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 253

Servo Parameters

Chapter 7

7-107

The parameters in this section are typically used on systems where friction

is a problem. Symptoms of high friction systems can include:

position error lag at the beginning of a move

position overshoot and slow recovery at the end of a move

position error on a circular quadrant boundaries

These parameters adjust the output torque of the system to overcome the

dynamic friction that occurs during a move, or the static friction (stiction)

that occurs at the start of a move.

Friction parameters are used on all digital systems and on analog systems

that use the Tachless Software Velocity Loop feature (loop type digital or

position/velocity).

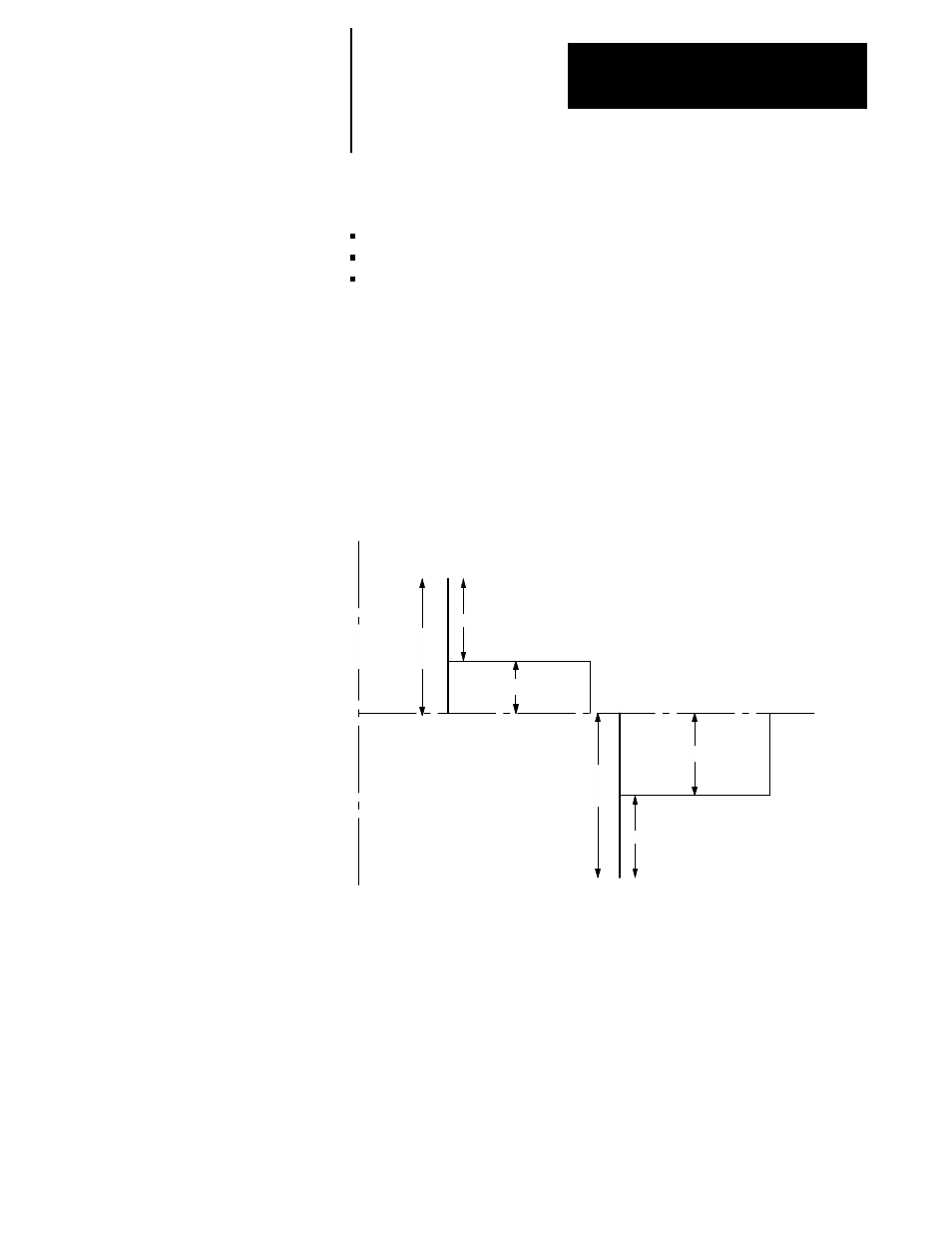

The following figure illustrates a positive and negative move showing the

amount of torque to initiate a move is higher than the torque necessary to

keep the axis moving.

Time

% Motor Rated

Torque

0

Positive Dynamic Friction

Stiction Compensation Torque

Stiction Compensation Torque

Negative Dynamic Friction

% Torque Needed to Overcome

Negative Static Friction

(Stiction or Breakaway Torque)

% Torque Needed to Overcome

Positive Static Friction

(Stiction or Breakaway Torque)

Note: The % Torque applied to overcome the

positive or negative static friction is equal to the

sum of the stiction compensation torque and the

dynamic friction torque.

7.6

Friction Parameters