12 minimum programmable jerk – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 319

Acc/Dec Parameters

Chapter 10

10-23

Function

Use this parameter when in S--Curve Acc/Dec (G47.1) mode to specify the

minimum allowable jerk value that the part program can set for each axis

used in a G48.5 block. Programming G48.5 values that are out of range

generates the decode error, “RAMP/JERK OUT OF RANGE”.

Minimum Programmable Jerk is also used at PTO to allocate the S--Curve

filter size buffer, with a maximum size of 60 iterations (1.20 sec) and a

minimum size of 2 iterations (0.04 sec).

To calculate the Minimum Programmable Jerk value:

1.

Determine the maximum acceleration value and the appropriate units

(e.g., g) using S--Curve Acceleration parameter. Refer to page

10-11 for more information about S--Curve acceleration.

2.

Determine the coarse iteration value in milliseconds using the System

Scan Time parameter. Refer to page 33--15 for more information

about system scan time.

3.

Determine the maximum linear velocity (i.e., rapid feedrate) and the

appropriate units (e.g., IPM) using the Rapid Feedrate for

Positioning parameter. Refer to page 9-2 for more information about

rapid feedrate for positioning.

4.

Enter the values from steps 1 to 3 into the spreadsheet located on the

MC Electronic Bulletin Board (440--646--3963). If you do not have

access to the Bulletin Board, the system will prompt you with further

instructions.

Once these values are entered, Excel will return the minimum and

maximum programmable jerk values. To manually calculate the minimum

programmable jerk value, refer to page 10-24.

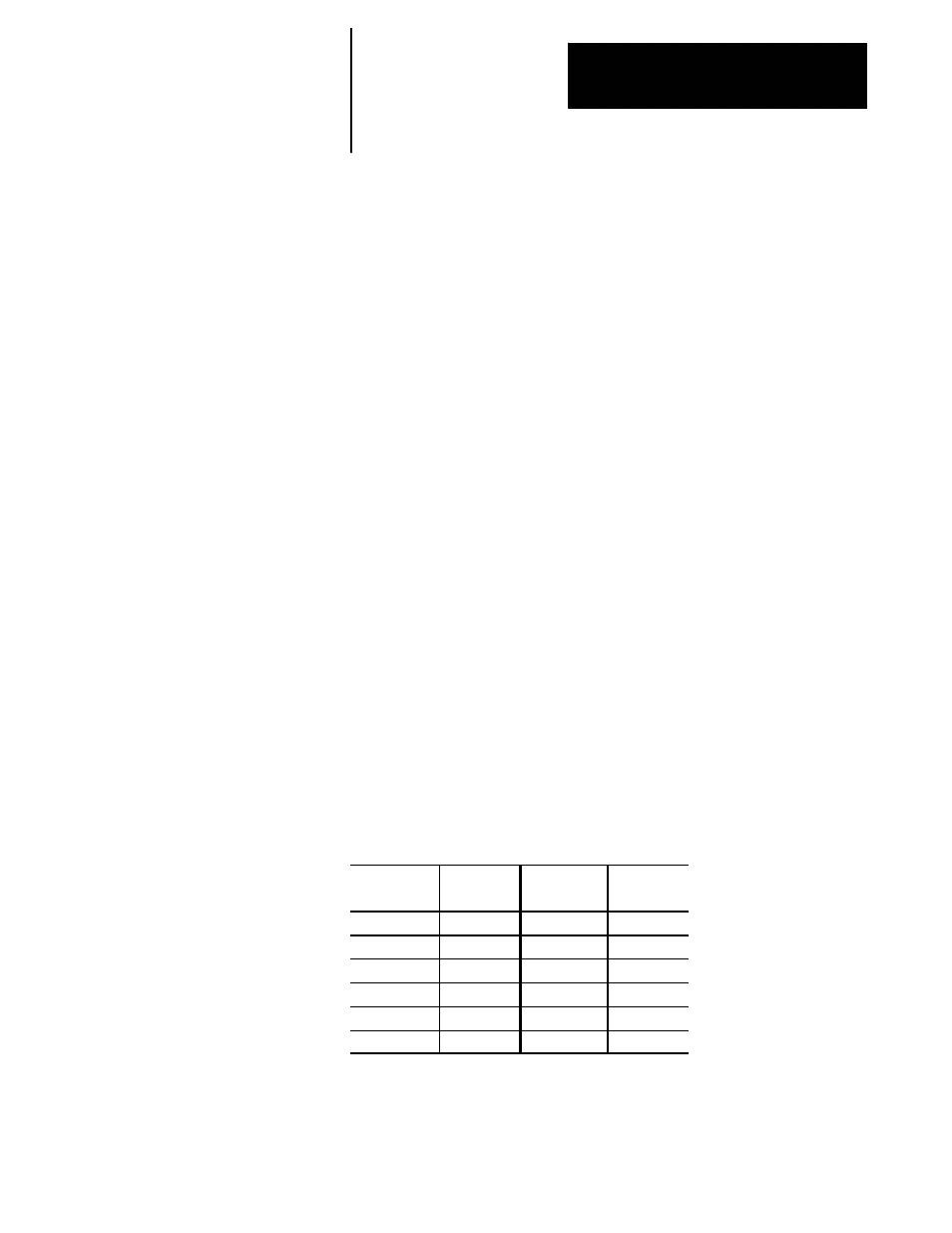

Axis

Parameter

Number

Axis

Parameter

Number

(1)

[1215]

(7)

[7215]

(2)

[2215]

(8)

[8215]

(3)

[3215]

(9)

[9215]

(4)

[4215]

(10)

[10215]

(5)

[5215]

(11)

[11215]

(6)

[6215]

(12)

[12215]

Range

0.00000 to 1,000,000.0000 mm/sec/sec/sec

10.12

Minimum Programmable

Jerk