5 default position offset – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 389

Spindle Synchronization

Chapter 15

15-7

Function

This parameter denotes how much the controlling spindle’s marker leads

the follower spindle’s zero position during positional synchronization. The

zero point is determined by the marker and Spindle Marker Calibration

(page 12-13, 13-14, or 14-14). If a positional value is programmed in the

part program block, this default position offset value is ignored. This

parameter will also apply to any spindle orients that take place while

positional synchronization is active. For example, if a default position

offset parameter = 60.0, when the controlling spindle is oriented to 80

degrees, the follower spindle should be at 20 degrees if the synchronization

direction is normal, or --20 if the synchronization direction is reversed.

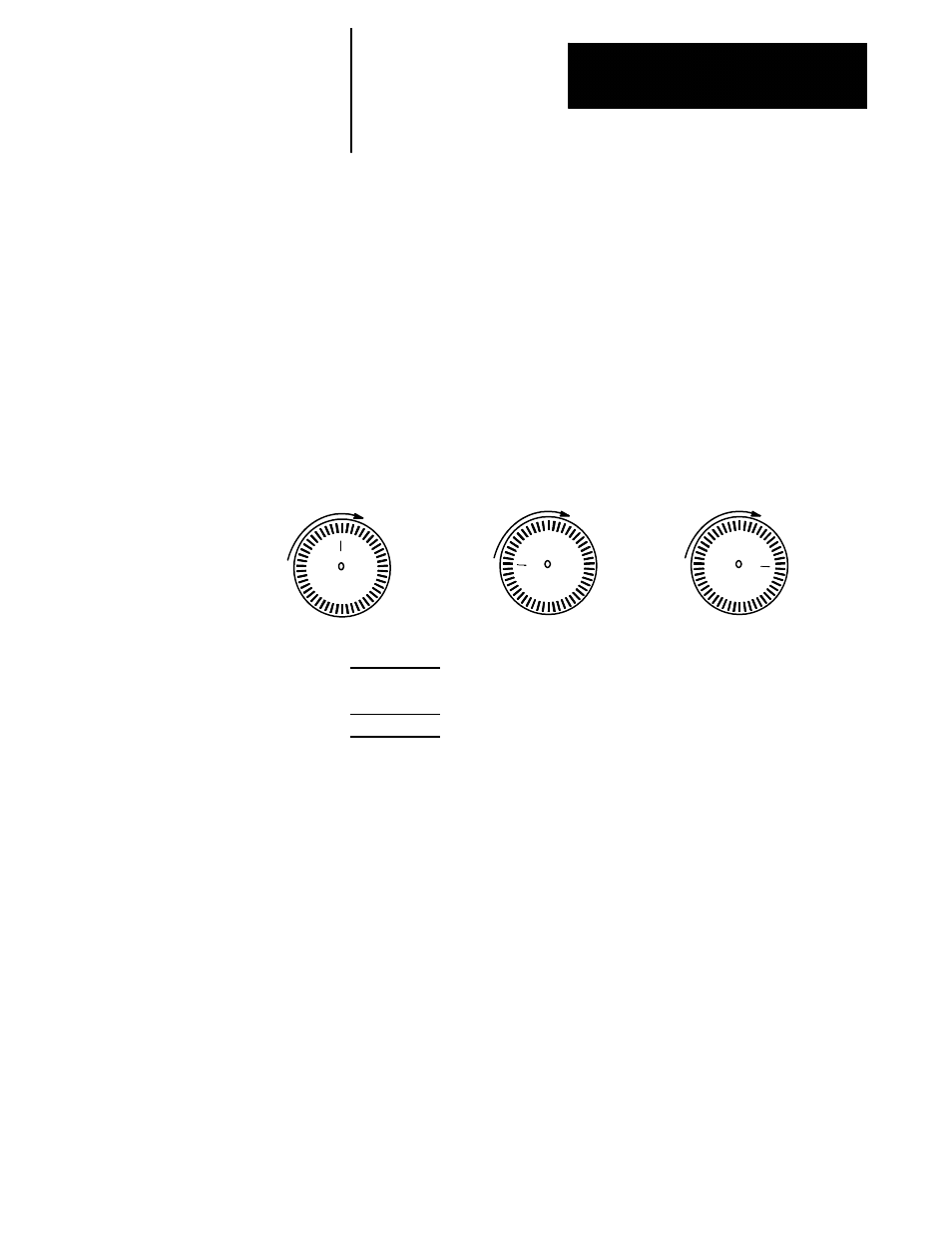

Figure 15.1

Aligning Controlling and Follower Encoder Markers

In this example, the controlling

spindle marker is positioned

at 0. The follower spindle’s

zero position is offset 90

degrees from the controlling

spindle’s position in normal

and reversed positions.

Controlling

Follower

Normal

Follower

Reversed

Parameter

Number

[594]

Range

0.000 to 360.000 degrees

Notes

This is a global parameter. The value set here applies to both spindles.

Threading with synchronization active will use the controlling spindle

marker. In a multiprocess 9/Series, the process not in spindle

synchronization mode will use the marker for the spindle configured for

that process.

15.5

Default Position Offset