Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 740

Integrating a Linear Feedback Device

Appendix B

B-2

The feedback from the scale should produce an A quad B signal that

matches the required signature given in chapter 7 of this document.

Quadrature error should be less than 27 degrees. Scales with single--ended

inputs are not supported.

To properly configure the position loop you must identify to the control the

type of feedback device expected, and the number of feedback counts that

should be expected per unit of axis travel.

The following AMP parameters have special configurations required to

configure your linear scale. The remaining AMP parameters in chapter 7

may or may not apply to your servo setup depending on your specific

application.

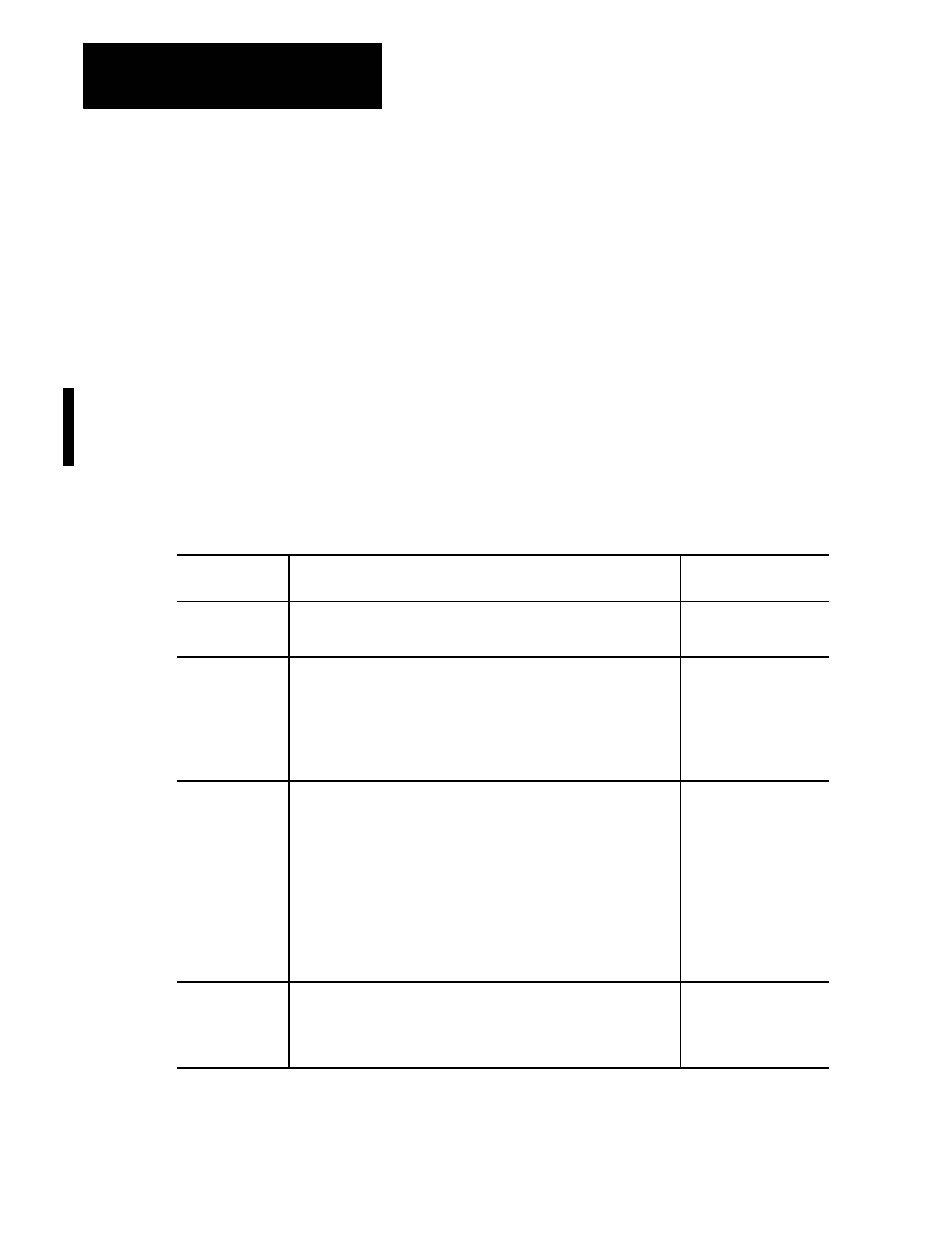

Table B.A

Position Loop Parameters

AMP Parameter

Description

Value for Heidenhain

Distance--coded Marker*

Position Feedback

Type

Selects the type of position feedback device used. Three types of linear

scale hardware is supported. Select between A Quad B No Marker, A

Quad B One Marker, or Distance Coded Marker.

Distance--coded Marker

Lead Screw

Thread Pitch

A Quad B No or One Marker

: The lead screw thread pitch defines the

distance of one electrical cycle for these feedback devices (see Counts

per Cycle above). This is necessary because there is no actual physical

marker series to define the cycle.

Distance Coded Marker:

The entered lead screw thread pitch is not

used for position loop calculations when configuring distance coded

markers.

(enter actual lead screw

thread pitch for velocity

loop)

Position Feedback

Counts/Cycle

A Quad B No or One Marker:

The entered Lead Screw Thread Pitch

defines the distance of one cycle for these feedback devices. Enter the

number of feedback counts expected over the thread lead distance. For

example if you entered a one inch lead screw thread pitch you would

enter the number of counts expected from the scale over that one inch of

travel. If the number of counts expected is greater than the allowable

number of counts simply enter a smaller lead screw thread pitch. If you

are forced to enter a lead screw thread pitch other than the actual screw

pitch, you may need to compensate when configuring gear ratios for the

velocity loop.

Distance Coded Marker:

The number of feedback counts expected for

the distance equal to the entered Smaller Periodic Distance.

20,000

Smaller Period for

DCM Scales

This parameter is used for scales with distance coded markers only. The

distance coded marker supported by the 9/Series must have equally

spaced odd and even markers. The distance between every odd marker

must be the same. The distance between every even marker must be the

same. For this parameter enter the smaller of these two distances.

20 mM

B.2

Configuring the Position

Loop with Linear Feedback