Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 663

Miscellaneous Parameters

Chapter 37

37-23

Determining System Scan TIme

Once you have determined your system foreground time, you can use the

timer function on the control to determine the total part program time.

With this information, you can calculate the optimum system scan time for

your system. Use this procedure:

1.

Set the system scan time well above the expected final setting. Since

you know the system foreground time from the system timer screen,

you only need to estimate how long it will take the control to

complete background tasks and decode the part program. Add this

estimate to the system foreground time to set the system scan time.

2.

Press the {TIME PARTS} key and run your program as described in

your programming and operation manual.

3.

When the program finishes, note the CYCLE TIME value. This value

is how long it took the control to decode the part program.

4.

Lower your system scan time. This can be done with either Offline

AMP or Online Patch AMP.

5.

Run your program again and note the cycle time. It should be

slightly lower than the previous time.

6.

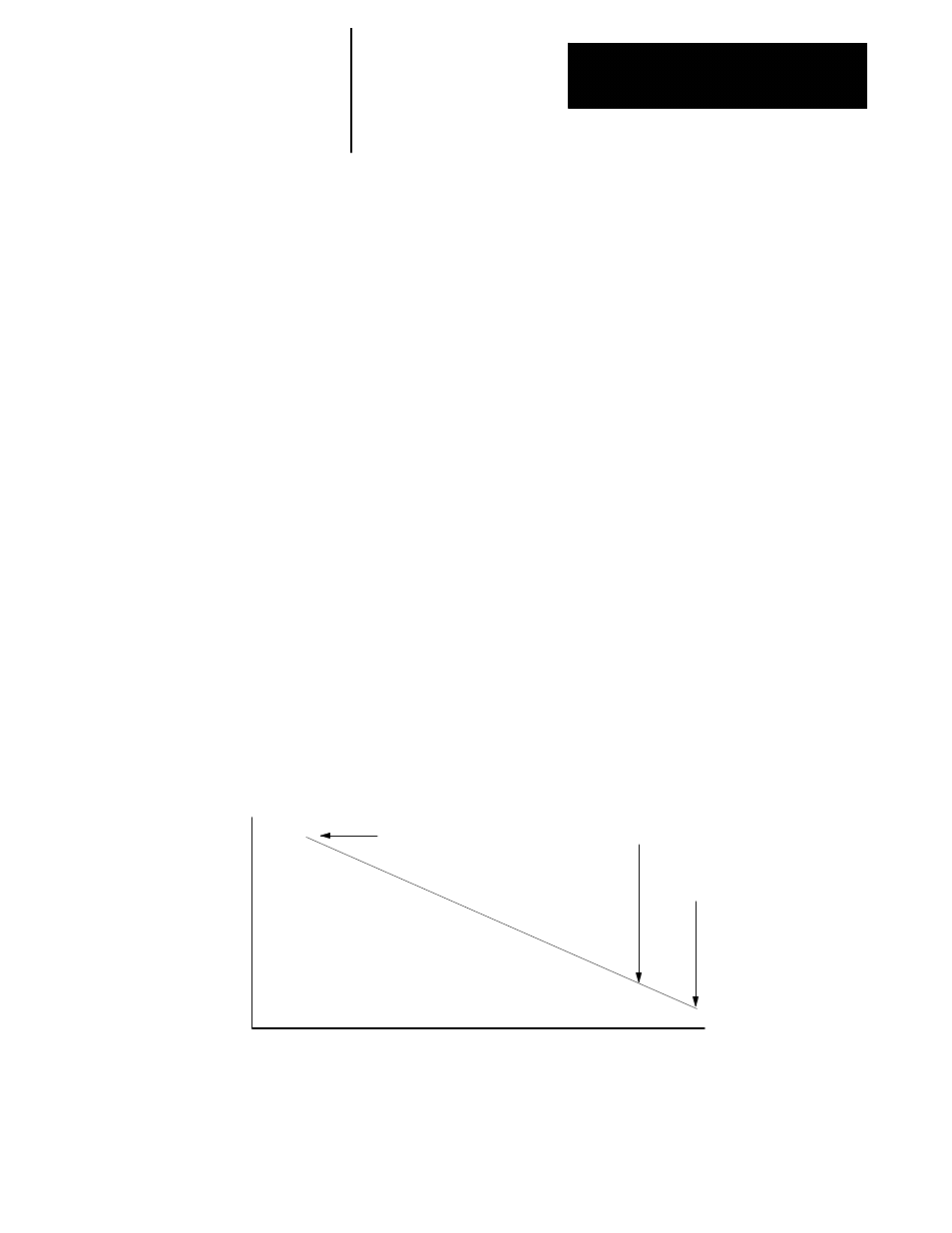

Repeat the sequence of lowering the system scan time and observing

the cycle time. As you lower the system scan time, the cycle time

decreases until the error message “Hardware Error #13” or

“Foreground Overlap” appears as shown in Figure 37.3. The point at

which you have the lowest cycle time and lowest system scan time is

when your system is running most efficiently.

Figure 37.3

Determining System Scan Time

Cycle Time in minutes

System Scan Time in ms

1:17

1:15

1:12

1:09

1:07

22

20

18

16

14

12

10

8

6

Optimal System Scan Time is when the

Cycle Time and System Scan Time are the

lowest before error messages appear.

Begin tracking the cycle time

when the system scan time is set

at the highest estimate.

”Foreground Overlap“ appears.

”Hardware Error #13“ or