Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 22

Using This Manual

Chapter 1

1--2

monitor and command peripheral devices such as tool turrets, part clamps,

and coolant systems. Refer to your PAL reference manual for additional

information.

AMP lets you:

define basic parameters such as system resolution and axis types that

affect the overall operation of the control

These parameters are called global control parameters.

define individual axis parameters such as soft travel limits, position

tolerances, and feedback constants

These parameters are called control parameters.

define individual process parameters such as assign axes and spindles to

a process, name the process and set priority

set up an axis calibration table for each axis to adjust for mechanical

deficiencies in the machine (On-line AMP only)

Default parameters are present in the control’s memory, even if the

control’s AMP memory is accidentally erased. The default values provide

a base from which to set up the machine.

Important: We wrote this manual to include mills, transfer line stations,

lathes, and surface and cylindrical grinders. The majority of sample

screens show a Mill/Lathe application type and a mill or lathe control type.

The parameter groups differ depending on the selected application type and

the selected control type.

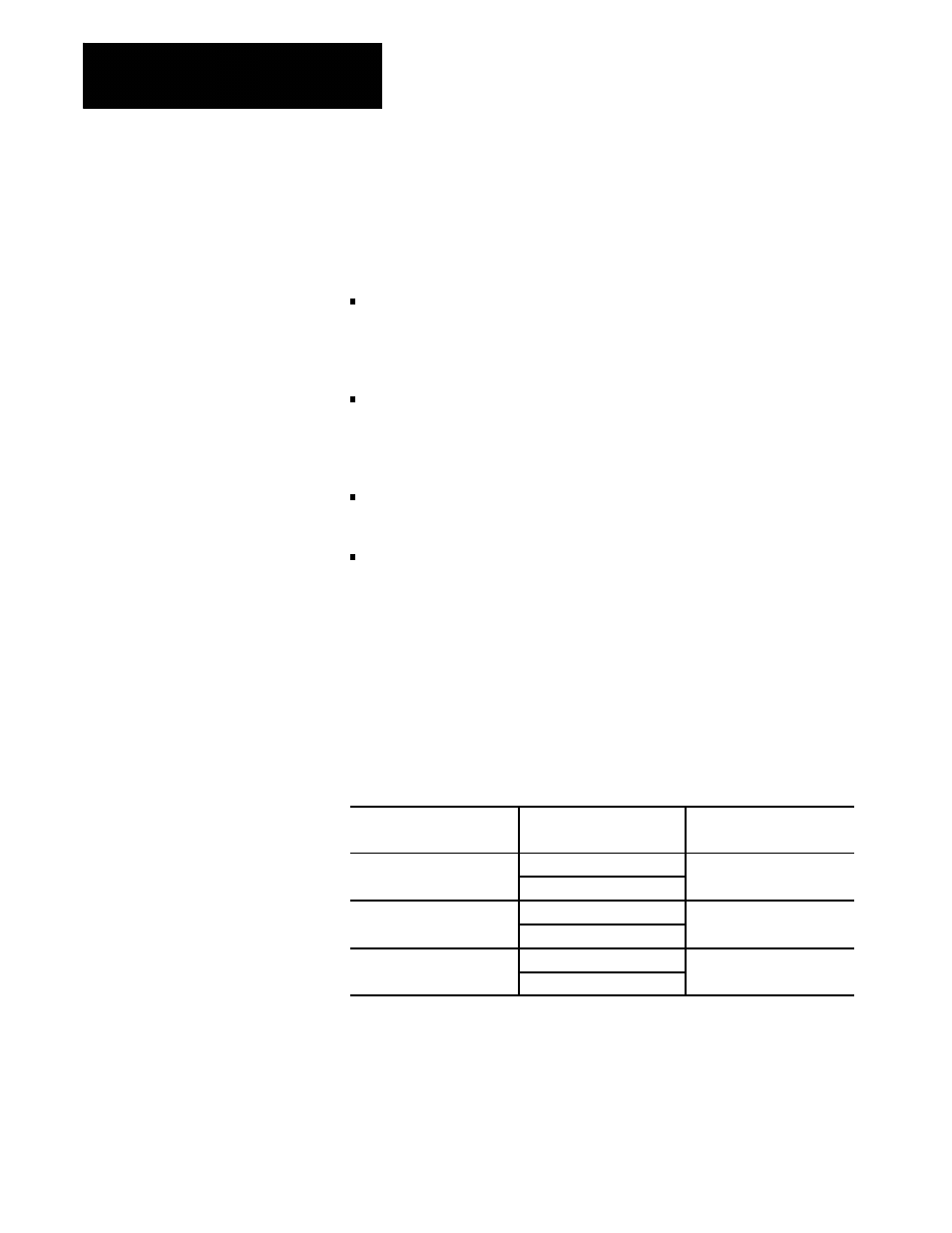

If, as an application type,

you selected:

these control types are

available:

and the default value is:

Mill/Lathe

lathe

lathe

mill

Grinder

surface

cylindrical

cylindrical

Dual--Processing Mill/Lathe

lathe

lathe

mill

Transfer line applications use the mill configuration type. The transfer line

option is selected using the Mill Type parameter found in the

Miscellaneous Parameter group.