2 velocity feedback type – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 208

Servo Parameters

Chapter 7

7-62

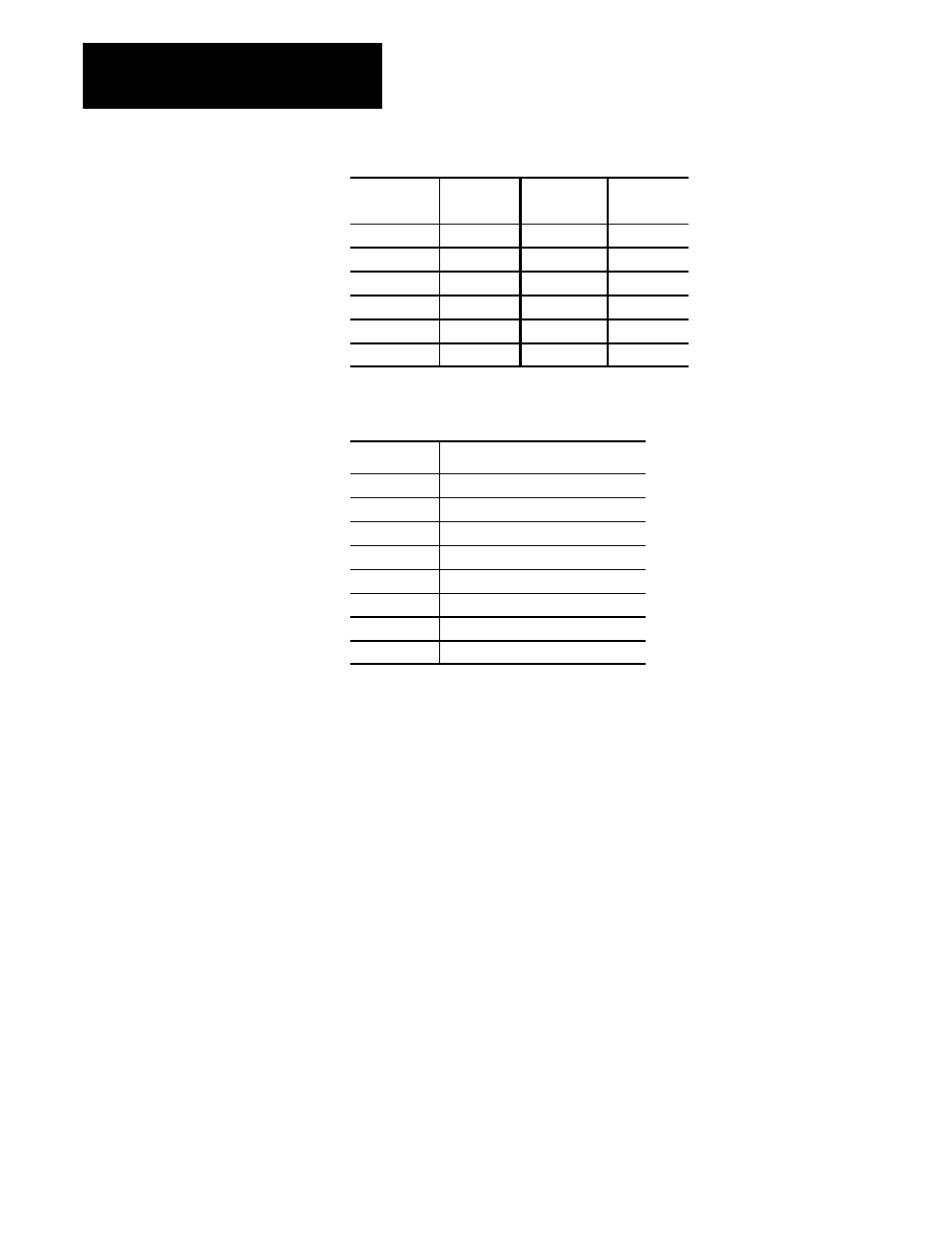

Axis

Parameter

Number

Axis

Parameter

Number

(1)

[1520]

(7)

[7520]

(2)

[2520]

(8)

[8520]

(3)

[3520]

(9)

[9520]

(4)

[4520]

(10)

[10520]

(5)

[5520]

(11)

[11520]

(6)

[6520]

(12)

[12520]

Range

Selection

Result

(a)

No Feedback

(b)

Feedback Connector J1 or CN5

(c)

Feedback Connector J2 or CN6

(d)

Feedback Connector J3 or CN7

(e)

Feedback Connector J4

(f)

Feedback Connector J9

(g)

Feedback Connector J10

(h)

Feedback Connector J11

Notes

This parameter must be set independently for each servo.

Function

The standard servo feedback configuration uses one feedback device for

both positioning and velocity data. If this is the case on your system, this

parameter must be set to the same value as the parameter Position

Feedback Type. Refer to this chapter’s overview for an example of a

system that uses two feedback devices for the same servo and may require

a different feedback type to be selected here.

Though the analog servo interface does not support a separate feedback

device for the velocity loop, you must still configure these velocity loop

parameters including Velocity Loop Feedback Port, Velocity Loop

Feedback Type, Velocity Feedback Counts/Cycle, and Sign of Velocity

Feedback. These parameters must be set to the same values as their

positioning loop counterparts.

7.3.2

Velocity Feedback Type