16 teeth on lead screw for position feedback – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 202

Servo Parameters

Chapter 7

7-56

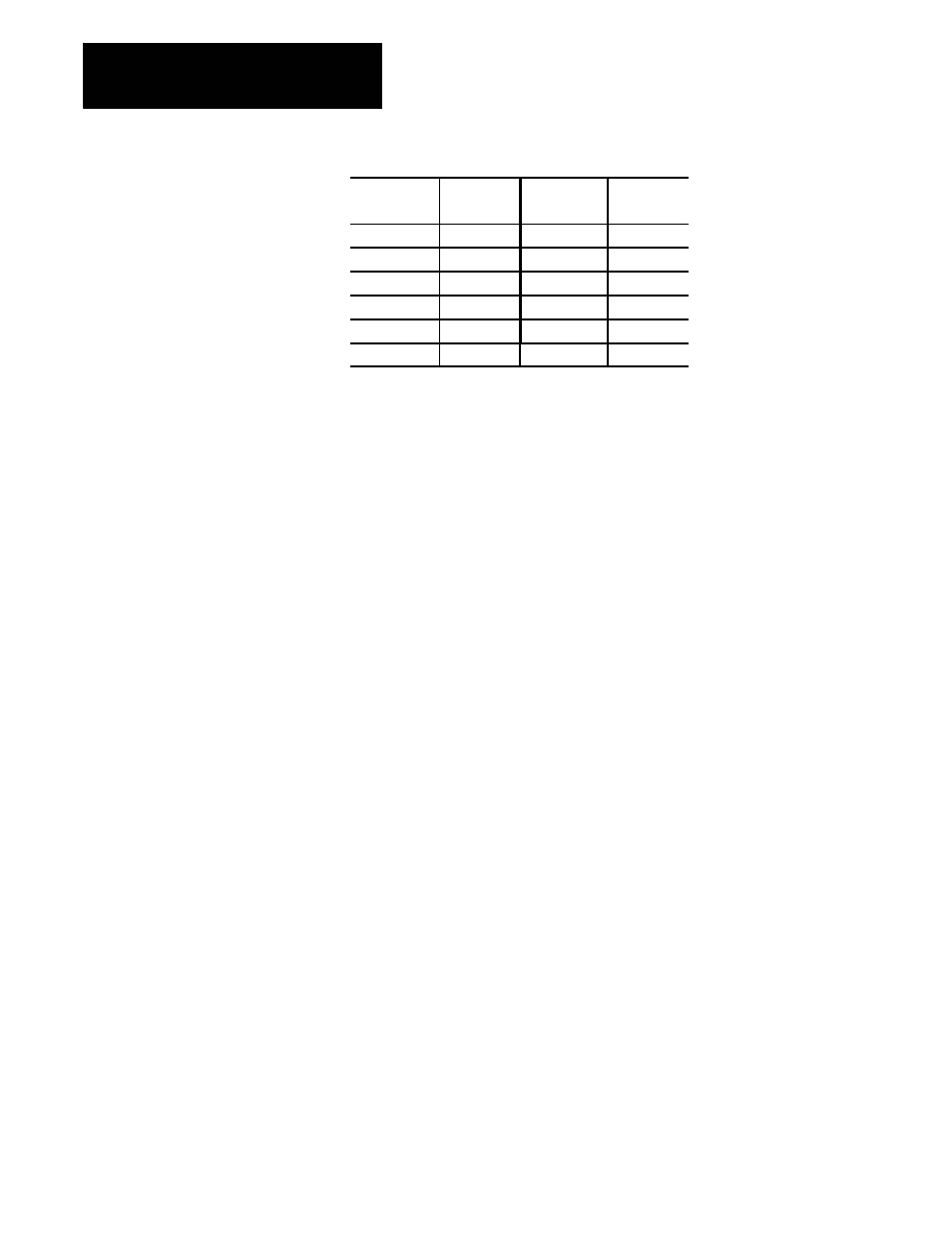

Axis

Parameter

Number

Axis

Parameter

Number

(1)

[1026]

(7)

[7026]

(2)

[2026]

(8)

[8026]

(3)

[3026]

(9)

[9026]

(4)

[4026]

(10)

[10026]

(5)

[5026]

(11)

[11026]

(6)

[6026]

(12)

[12026]

Range

1 to 32767

Notes

When configuring any closed--loop axis you must configure two gear ratios

for feedback; one for velocity feedback, the other for position feedback.

On axes with a single feedback device, the setup and gear ratios should be

identical for position and velocity feedback since the same device is being

used for both feedback types.

This parameter must be set independently for each axis.

Function

If you are using the same physical device for both the velocity loop and

position loops, then the value entered for this parameter should be the same

as the value entered for the parameter Teeth on Motor Gear For Vel FB .

If you are using a non--motor--mounted position feedback device

(connected to a different feedback port than the velocity feedback), enter

the number of teeth on the gear or gearbelt pulley attached to the lead

screw. This number is used in conjunction with the parameter Teeth on

Gear for Position FB to calculate the gear ratio from the position

feedback device to the lead screw (number of lead screw revolutions that

occur between position feedback device revolutions). The control then

uses this ratio combined with the entered Lead Screw Thread Pitch and

Position Feedback Counts/Cycle to determine the number of feedback

counts that occur per unit of axis travel.

7.2.16

Teeth on Lead Screw for

Position Feedback