8 spindle orienting parameters – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 359

Spindle 2 Parameters

Chapter 13

13-13

These parameters are relevant only if your spindle provides position

feedback and is capable of orienting to a specific position.

Important: It is possible to perform coarse spindle orients without

position feedback through proper PAL programming and the use of

mechanical switches mounted on the spindle mechanism. These

parameters are not relevant for such an application.

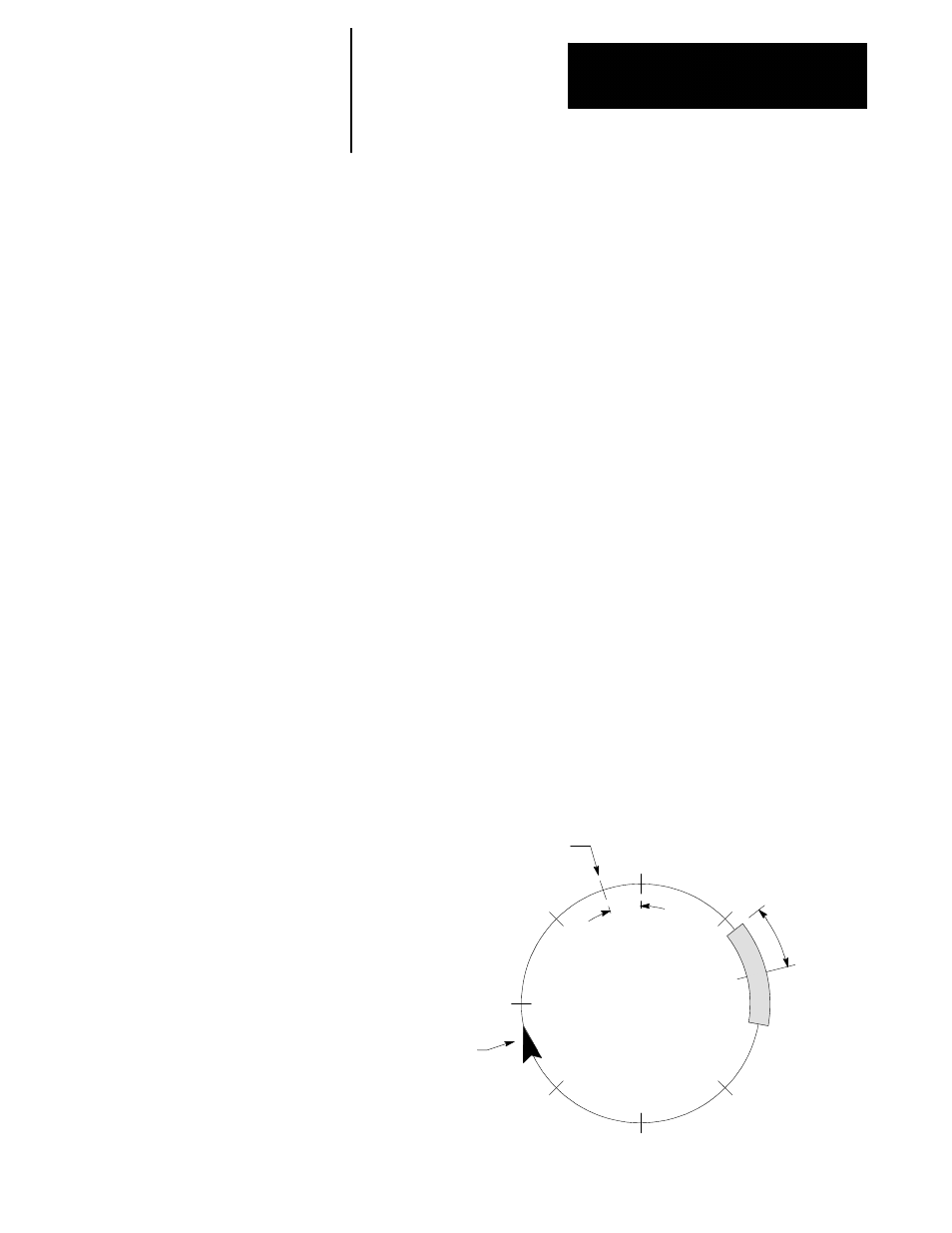

The spindle orient feature (Figure 9.1) lets the control stop the spindle at

either a predefined angle set in AMP or a programmed angle. The spindle

orient feature is discussed in your lathe or mill programming and operation

manuals.

Spindle Homing

Spindle homing is performed automatically when the control enters spindle

orient mode (M19). (Note that spindle homing may also be forced when

the spindle enters the virtual C mode as discussed in chapter 28.) Spindle

homing consists of the spindle decelerating to the orient spindle RPM, and

finding the encoder marker (or null position). Once this position is found,

the spindle moves on to the spindle marker calibration point that

determines the location of the zero point of the spindle relative to the

encoder marker position. After this location is reached, the spindle moves

to the location requested in the M19 block.

Important: Note that the use of a spindle with feedback must have only

one encoder marker per revolution of the spindle. If more than one

encoder marker is present, inconsistent homing results depending on which

marker is found first when the spindle homing operation is activated.

Figure 13.1

Parameters for Spindle Orient

ORIENT DIRECTION

Typically this is positive ( + )

as viewed from headstock

Encoder marker position

relative to spindle rotation

0 degree

ORIENT

INPOSITION

BAND

Typical

commanded

position

SPINDLE

MARKER

CALIBRATION

distance

13.8

Spindle Orienting

Parameters