3 feedrate for (f1 - f9) – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 291

Feedrate Parameters

Chapter 9

9-9

Function

Use these 9 parameters to determine the feedrate when a single-digit

feedrate word is programmed. These values are used when a feedrate is

programmed as a whole integer value (F1 through F9).

When the control executes a one-digit feedrate word, F1 through F9, it

automatically sets the feedrate at the value of the corresponding parameter.

This feature lets programmers easily specify frequently required feedrates.

Also, the feedrates can be changed without changing the part program,

since only parameters need be changed. These parameters may also be

changed on-line. Refer to chapter 13 of your programming and operation

manual for additional information on feedrates.

These one-digit feedrates are entered as either IPM or MMPM values, and

apply only when the control is in the IPM/MMPM feedrate mode (G94).

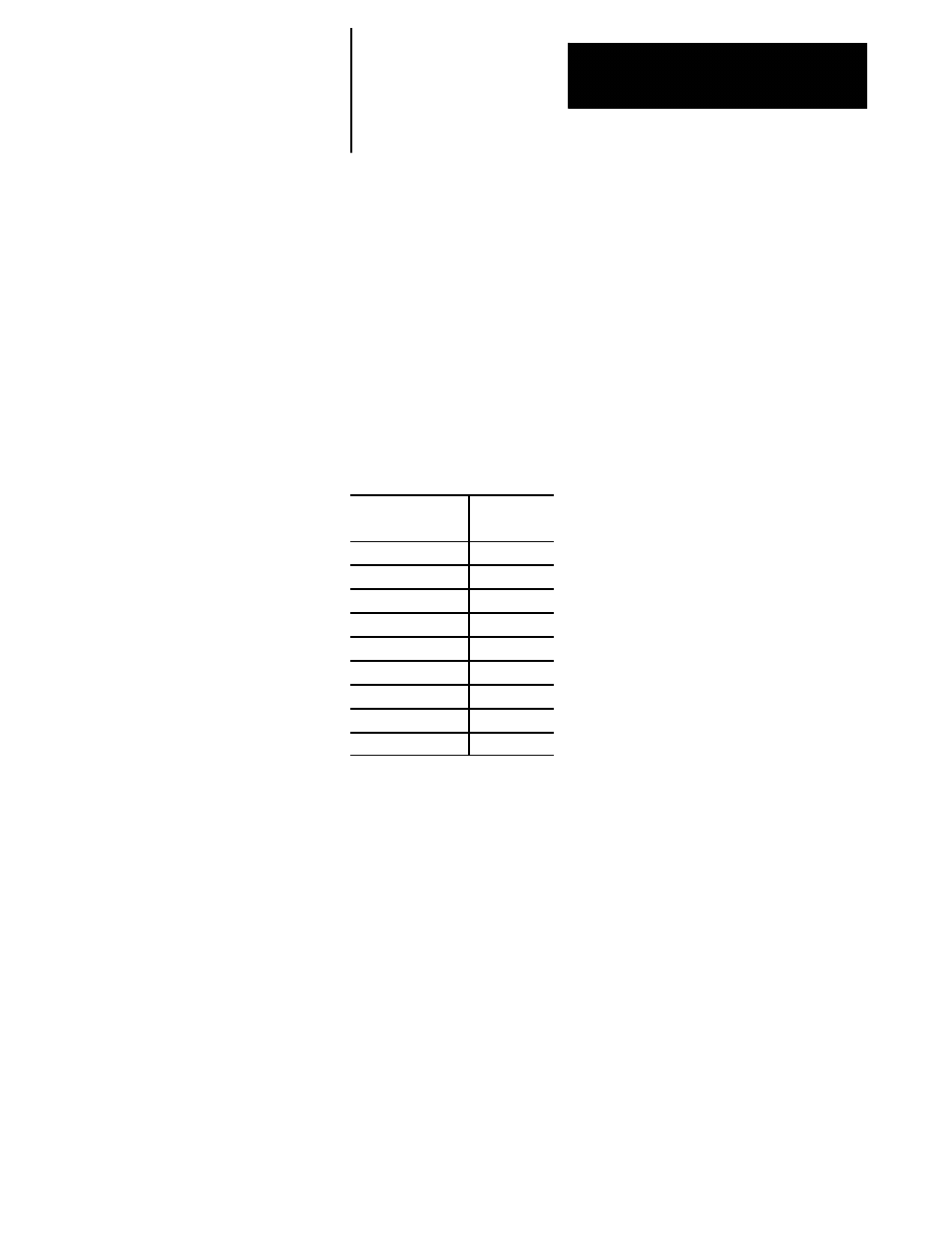

Parameter

Parameter

Number

Feedrate for F1

[423]

Feedrate for F2

[424]

Feedrate for F3

[425]

Feedrate for F4

[426]

Feedrate for F5

[427]

Feedrate for F6

[428]

Feedrate for F7

[429]

Feedrate for F8

[430]

Feedrate for F9

[431]

Range

0.00000 to 10160.00004 mmpm

or

0.00000 to 400.00000 ipm

Notes

If a value of 0 is entered for these parameters, the control handles a

single-digit F-word as a standard F-word. For example, F2 may cause a

feedrate of 2 IPM/MMPM.

Programming an F0 calls for the Maximum Cutting Feedrate for each axis.

This is a global parameter. The value entered here applies to all axes.

When the control powers up F1 is the default feedrate override on a

push-button MTB panel.

9.3

Feedrate for (F1 - F9)