Cutter comp/tool tip radius, 0 chapter overview, Chapter – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 501

Chapter

23

23-1

Cutter Comp/Tool Tip Radius

This chapter describes the Cutter Compensation and Tool Tip Radius

Compensation (TTRC) parameters. This lets the part programmer program

the path the tool follows in terms of the tool’s center or gauge point

without regard to the diameter or tool-tip radius.

The Cutter Compensation and TTRC parameters are broken into

two sections:

Parameter:

Page:

Compensation basic setup

23-2

Compensation error detection

23-13

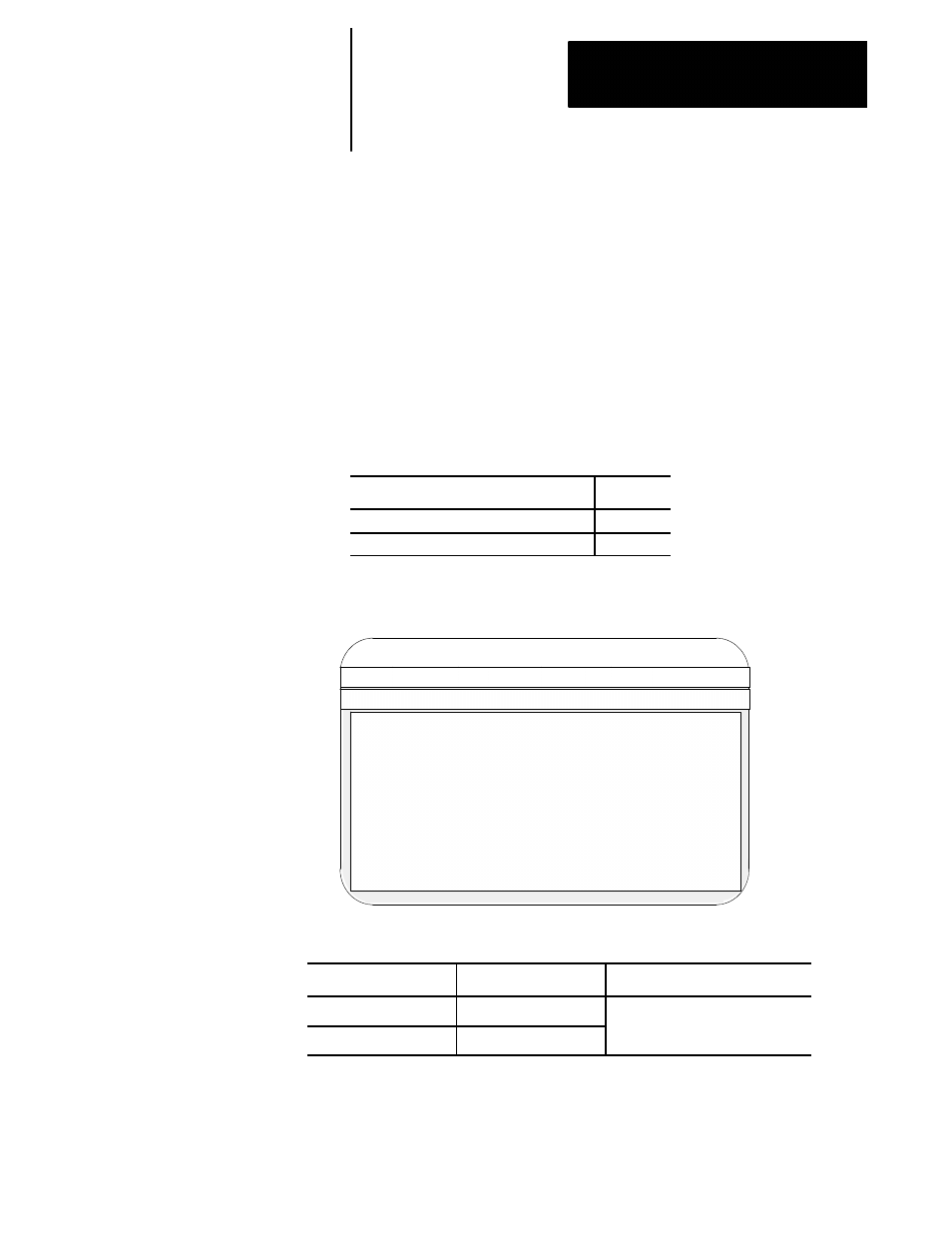

When you select “Cutter Comp/Tool Tip Radius” from the main menu

screen, this screen becomes available:

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

Control Type : Mill

Axis :

X - linear

File :

TEST

- Cutter Comp/Tool Tip Radius -

Cutter Compensation Type

:

Type A

Defines offset as Diam. or Rad

:

Diameter

Min Block generation length

:

0.01000 mm

Max number of non-motion blks

:

5

Interference detection

:

Enabled

Reverse comp motion detection

:

Enabled

M word to disable Interference

:

800

M word to enable Interference

:

801

Minimum feed reduction %

:

80 %

Corner override angle

:

90 Degree

Corner override distance (DTC)

:

2.54000 mm

Corner override distance (DFC)

:

2.54000 mm

Corner override %

:

80 %

These parameters also appear if the application type is Grinder and the control type is Surface.

If the application type is: and the control type is:

these parameters do not appear:

Mill/Lathe

Lathe

Defines offset as Diam. or Rad

Grinder

Cylindrical

For Dual Processing controls, these parameters are global and can not be

set per process. The values set apply to all processes.

23.0

Chapter Overview