Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 741

Integrating a Linear Feedback Device

Appendix B

B-3

AMP Parameter

Value for Heidenhain

Distance--coded Marker*

Description

Larger Period for

DCM Scales

This parameter is used for scales with distance coded markers only. The

distance coded marker supported by the 9/Series must have equally

spaced odd and even markers. The distance between every odd marker

must be the same. The distance between every even marker must be the

same. For this parameter enter the larger of these two distances.

20.02 mM

Machine Pos. at

DCM Scale 0

This parameter is used for scales with distance coded markers only. This

parameter is similar to the homing parameter “Axis Position After

Homing”. The value entered here is used to redefine the control’s

interpretation of the actual zero marker on the scale. Use this parameter

to shift the machine coordinate system on your scale. The value entered

here becomes the actual value of the zero marker.

0

Teeth on Gear for

Pos. FB

This parameter should be set to one. Entering something other than one

will change the final Counts per Cycle calculation based on the ratio

between this parameter and “Teeth on Lead Screw for Pos. FB”.

1

Teeth on Lead

Screw for Pos. FB

This parameter should be set to one. Entering something other than one

will change the final Counts per Cycle calculation based on the ratio

between this parameter and “Teeth on Gear for Pos. FB”.

1

* Assumes Heidenhain model LS176 with:

Grating period = 20 M (i.e., 20,000 cts/cycle)

Small period = 20mM

Large period = 20.02mM

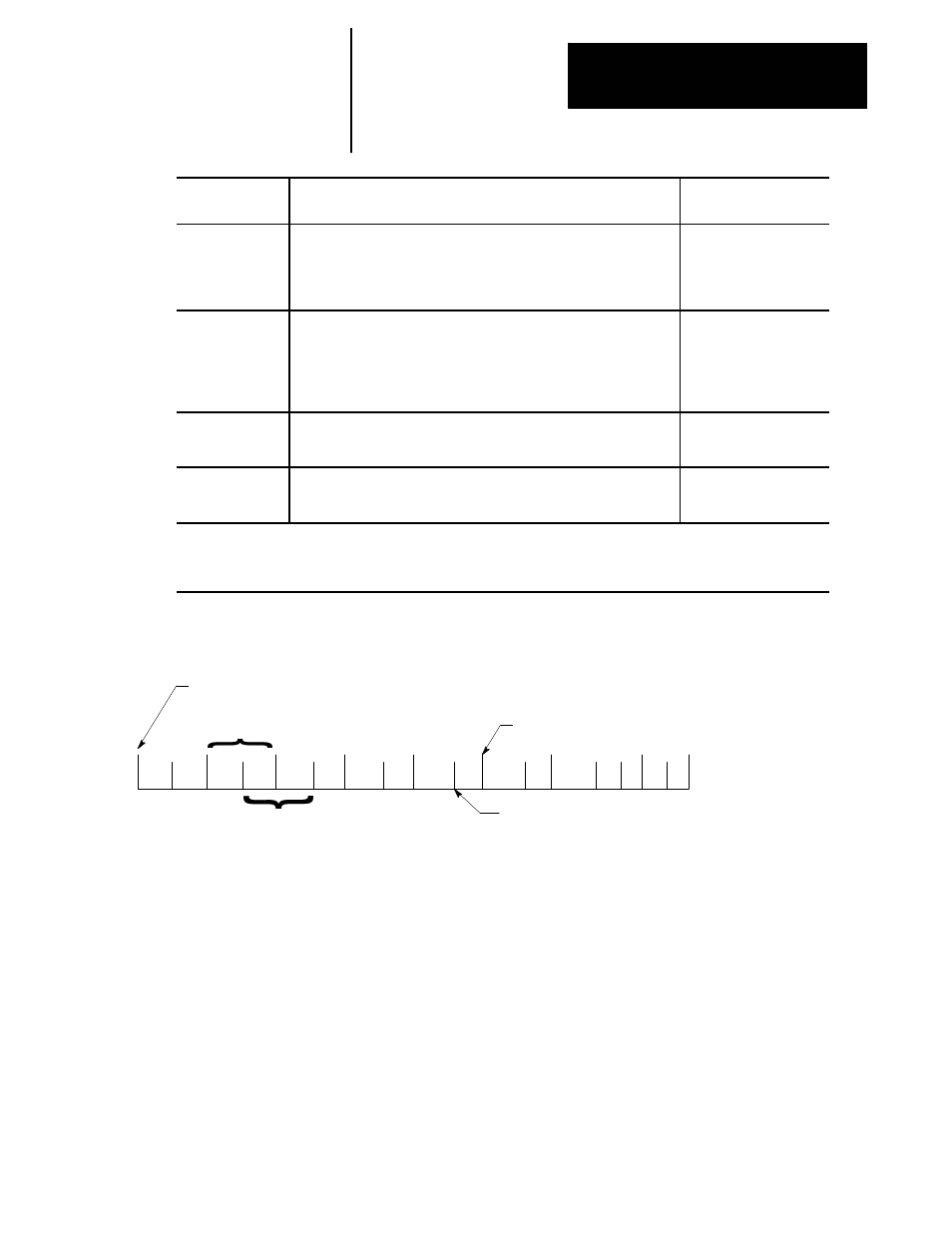

Figure B.1

Configuring a Scale with Distance Coded Markers

Smaller Period for DCM Scales (20.00)

Larger Period for DCM Scales (20.02)

Number of counts returned by scale in 1

Smaller Period defines Counts per Cycle.

Odd Markers

Even Markers

Assign this scale zero a new machine position

using “Machine Position at DCM Scale 0”