7 dev. detection filter time – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 338

Spindle 1 Parameters

Chapter 12

12-10

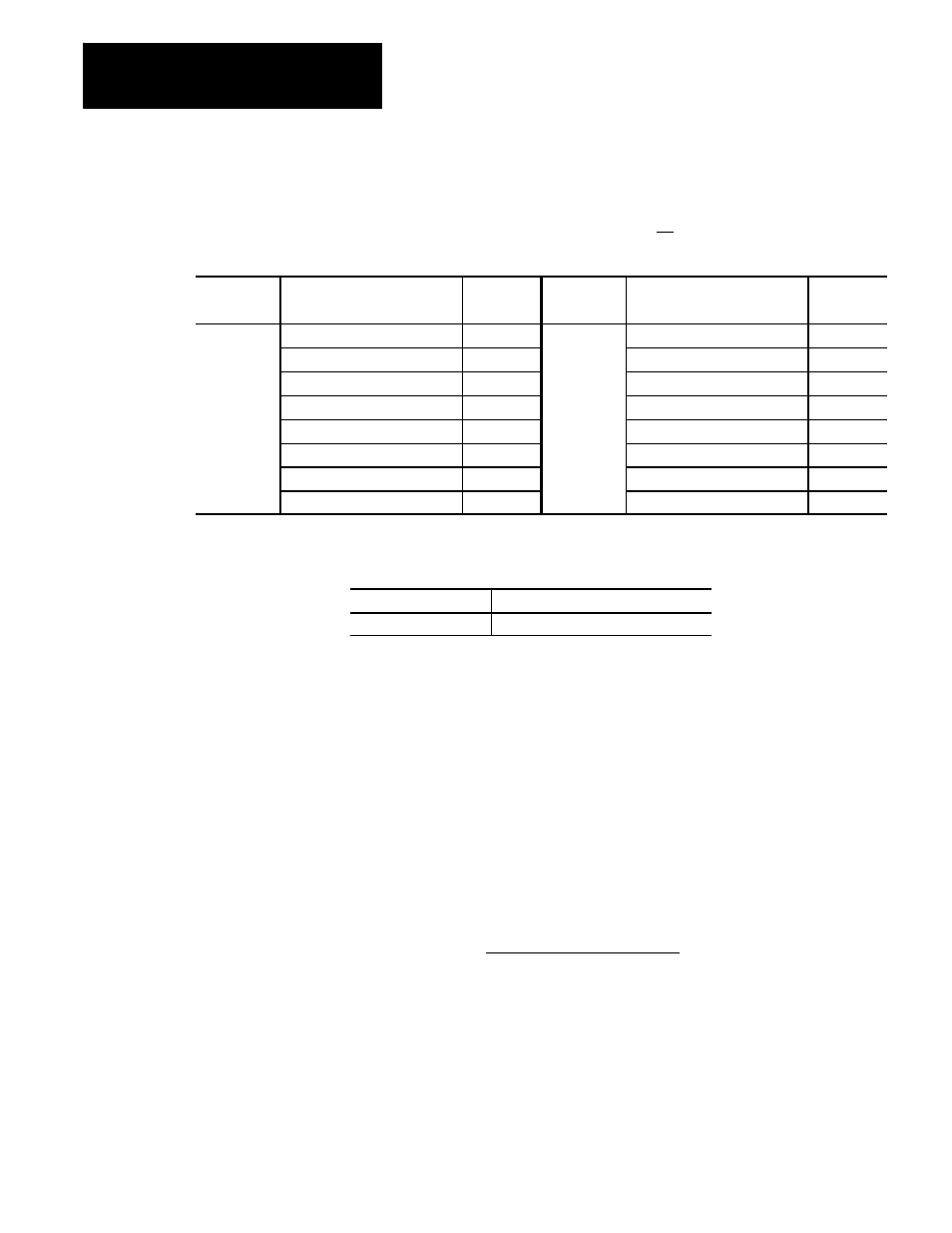

Values must be entered for all gear ranges specified by the parameter

Number of Gears Used. If any of the gears used has no value or an illegal

value entered here, the control assumes that no gears are available and

never requests a gear change.

Spindle

Parameter

Parameter

Number

Spindle

Parameter

Parameter

Number

All

Min. Spindle Speed - Gear 1

[900]

All

Max. Spindle Speed - Gear 1

[910]

Min. Spindle Speed - Gear 2

[901]

Max. Spindle Speed - Gear 2

[911]

Min. Spindle Speed - Gear 3

[902]

Max. Spindle Speed - Gear 3

[912]

Min. Spindle Speed - Gear 4

[903]

Max. Spindle Speed - Gear 4

[913]

Min. Spindle Speed - Gear 5

[904]

Max. Spindle Speed - Gear 5

[914]

Min. Spindle Speed - Gear 6

[905]

Max. Spindle Speed - Gear 6

[915]

Min. Spindle Speed - Gear 7

[906]

Max. Spindle Speed - Gear 7

[916]

Min. Spindle Speed - Gear 8

[907]

Max. Spindle Speed - Gear 8

[917]

Range

Min. Spindle Speed:

0 to Max. Spindle Speed (rpm)

Max. Spindle Speed:

Min. Spindle Speed to 99999.9(rpm)

Notes

This parameter must be set for each spindle axis.

Digital Spindle users must set this parameter (for gear 1 only) in addition

to setting the servo parameter “Maximum Motor Speed” to define valid

motor speeds.

Function

If spindle DAC output ramping is off:

This parameter specifies the spindle acceleration / deceleration time to be

used by the control only for simulated feedback. Simulated feedback is

explained with the parameter Spindle Deviation Tolerance.

Since the value entered here is used in simulating any change in speed

(regardless of whether it’s from 0 to 20 rpm, from 10 to 2000 rpm, or from

500 to 2000 rpm), it is recommended that an average time be entered.

12.7

Dev. Detection Filter Time