Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 203

Servo Parameters

Chapter 7

7-57

Important: If configuring a linear position feedback device (excluding

distance--coded marker systems) use the parameters Position Feedback

Counts/Cycle and Lead Screw Thread Pitch to enter the number of

counts returned by the device per revolution of the lead screw. The ratio

between Teeth on Gear for Position FB and the parameter Teeth on

Lead Screw for Position Feedback should be one to one. For example if

the linear device has 5000 lines per 1/2 inch enter 5000 as the Position

Feedback Counts/Cycle and .5 inch as the Lead Screw Thread Pitch.

Both Teeth on Gear for Position Feedback and Teeth on Lead Screw

for Position Feedback can then be set to one.

In some cases there may be a series of gears or gearbelt pulleys that make

up a final gear ratio for a servo. In this case, it is necessary to factor this

gear ratio into this parameter and the parameter Teeth on Gear for

Pos FB.

Important: The system automatically reduces the gear ratio to the lowest

common denominator. For example, a ratio of 44:40 will be reduced to

11:10 on an AMP upload.

Refer to Figure 7.31 for an illustration of typical gearing for position

feedback devices.

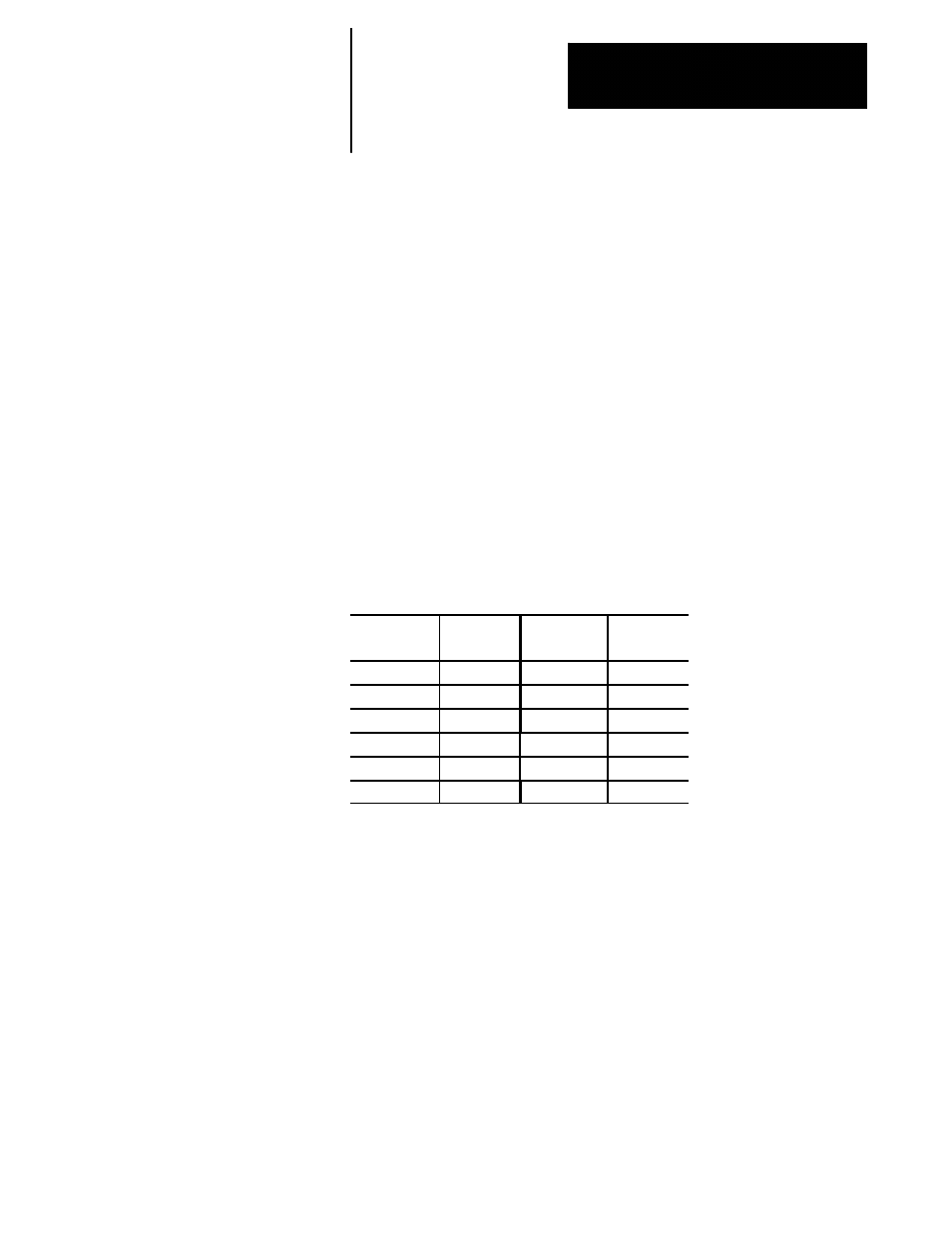

Axis

Parameter

Number

Axis

Parameter

Number

(1)

[1027]

(7)

[7027]

(2)

[2027]

(8)

[8027]

(3)

[3027]

(9)

[9027]

(4)

[4027]

(10)

[10027]

(5)

[5027]

(11)

[11027]

(6)

[6027]

(12)

[12027]

Range

1 to 32767

Notes

When configuring any closed--loop axis you must configure two gear ratios

for feedback; one for velocity feedback, the other for position feedback.

On axes with a single feedback device, the setup and gear ratios should be

identical for position and velocity feedback since the same device is being

used for both feedback types.

This parameter must be set independently for each servo.