Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 630

Deskew Parameters

Chapter 36

36-4

ATTENTION: Whenever two servos are configured to drive

one axis, you must use the deskew feature to control servo

misalignment. Failure to consider possible servo misalignment

may result in damage to drive components.

Each split axis can be driven by a maximum of two servo motors. The

control supports two split axis pairs in a 9/Series system. Dual process

systems can also have two split axis pairs total, however, only one pair per

process is allowed.

Aside from the parameters in this deskew group, you must configure the

servos that drive the split axis as normal independent servos, including:

separate feedback devices

feedback directions

loop type

axis name

Each servo axis has its own port configured for command, position, and

velocity. When configuring a split axis, keep the following in mind:

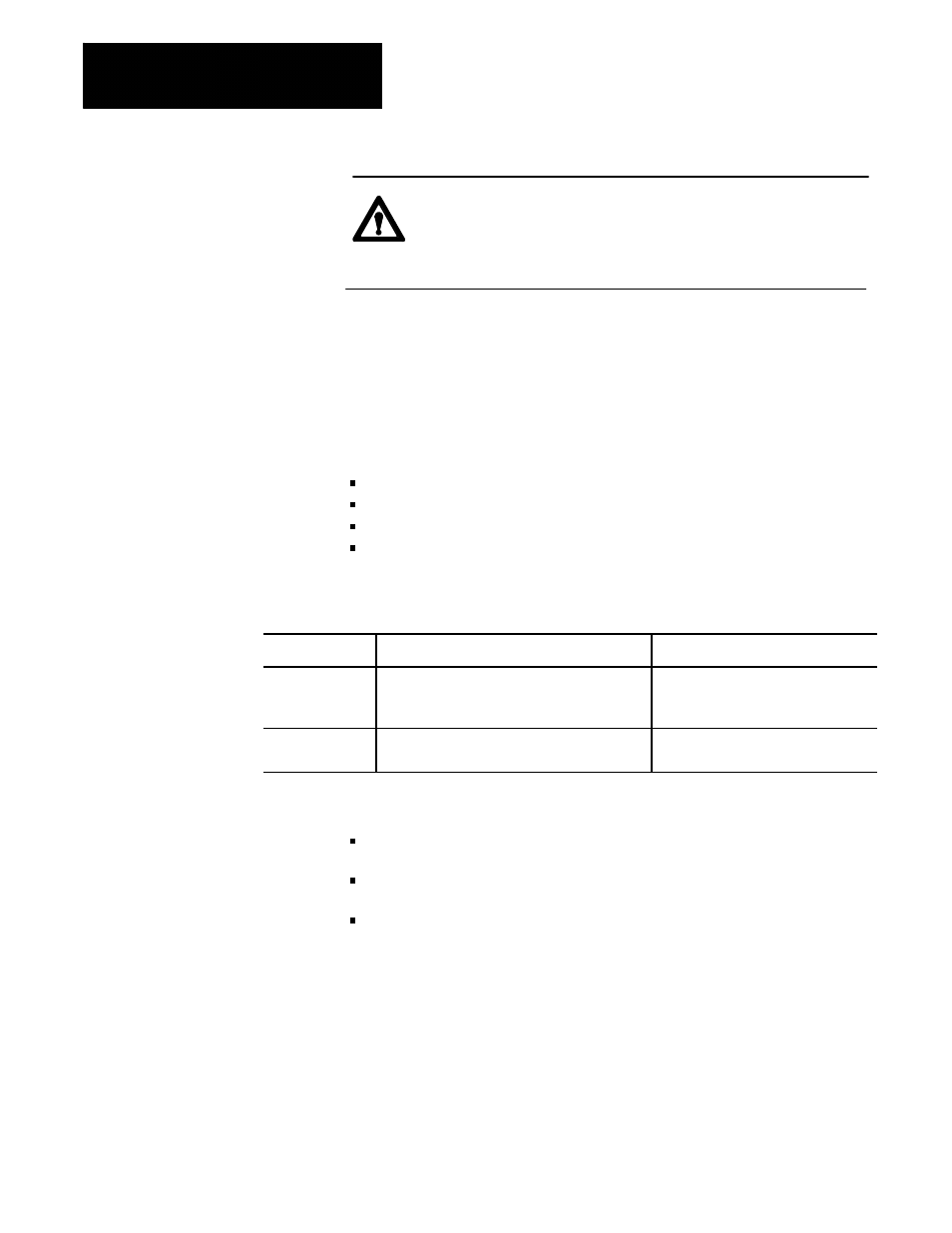

If

then the slave

and the master servo

One or more

spindles are

configured in AMP

must be AMP’d as the highest axis numbers in

each process before spindles. Spindles must be

the highest axis numbers used on a system.

can be configured as any axis before the

slave axis.

No spindles are

configured

must be AMP’d as the highest axis number used in

the process

can be configured as any axis before the

slave axis

Each servo in the split axis can be configured with independent:

Reversal Error values

Axis Calibration points

Home Calibration values

Many parameters, such as Acc/Dec, feedrates, etc., are shared between the

master servo and slave servo. These shared parameters are listed in this

chapter. (Deskew Master Servo Name).