Fixed cycles, 0 chapter overview, Chapter – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 521

Chapter

25

25-1

Fixed Cycles

This chapter describes the available milling and turning fixed-cycle AMP

parameters.

The fixed-cycle parameters are separated into these four sections:

Parameter:

Page:

Milling fixed-cycle parameters

25-3

Threading cycle parameters

25-10

Turning cycle parameters

25-16

7300 Tape Compatibility Parameters

25-18

Some of these parameters may also be changed on the control, as noted

below on with the fixed cycle parameters table.

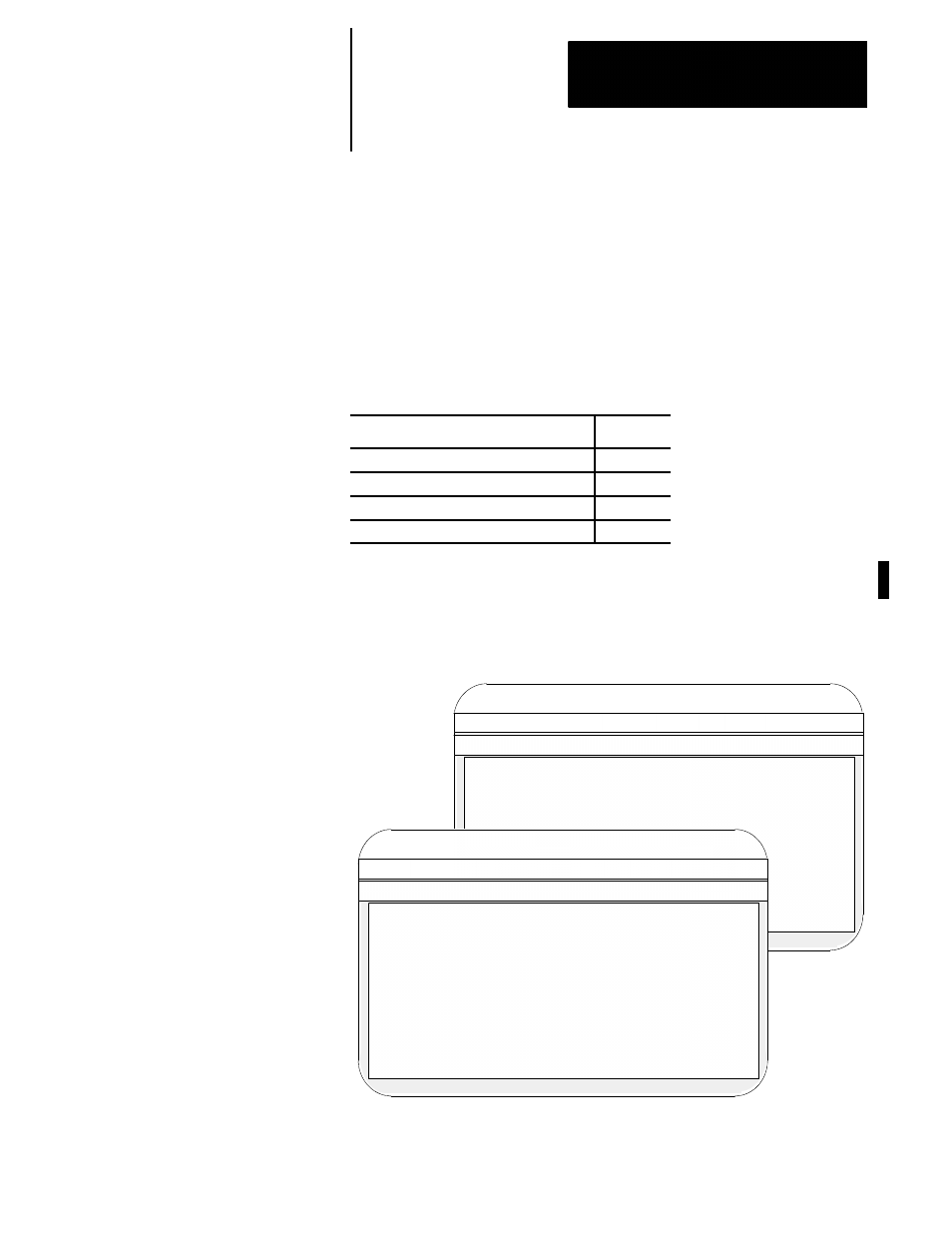

When you select the “Fixed Cycle Parameters” group and the control type

“Lathe,” the workstation displays these screens:

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Type : Lathe

Axis: X

P1:

File :

TEST

- Fixed Cycle Parameters -

Page 2 of 2

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

- Fixed Cycle Parameters -

Page 1 of 2

Retrct amt - Peck Drilling

:

25.40000 mm

Fine boring shift in Q-word

:

yes

Pullout angle, chamfered thrd

:

5.0 degrees

Pullout dist, chamfered thrd

:

5.080 Thread leads

Cycle clearance amount

:

25.40000 mm

Fine Boring shift dir. G17

:

G17 Primary axis 2 positive

Fine Boring shift dir. G18

:

G18 Primary axis 2 positive

Fine Boring shift dir. G19

:

G19 Primary axis 2 positive

Ignore dwell in tapping cycles

:

no

Rapid to Drilling Hole

:

yes

Always Repeat Turning Cycles

:

no

Fixed drilling axis

:

axis 3

Retract amount in grooving

:

0.00000 mm

Min infeed in multi threading

:

0.00000 mm

Finish allow in mult threading

:

0.00000 mm

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Type : Lathe

Axis: X

P1:

File :

TEST

25.0

Chapter Overview