10 add to tool offset for skip 1 - 4 – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 484

Tool Offset Parameters

Chapter 22

22-12

Function

Typically, when one of the G37 cycles is executed, the control moves

toward a programmed position. A signal is sent to PAL from a device

when contact is made between the tool and the device. The control then

subtracts the actual position of the tool when the signal is sent to PAL from

the programmed end-point of the move.

Use these parameters to determine whether the value generated as

described above is added to or replaces the current value in the table for

tool length (or radius value for mill versions when some axis other than the

tool length axis is used).

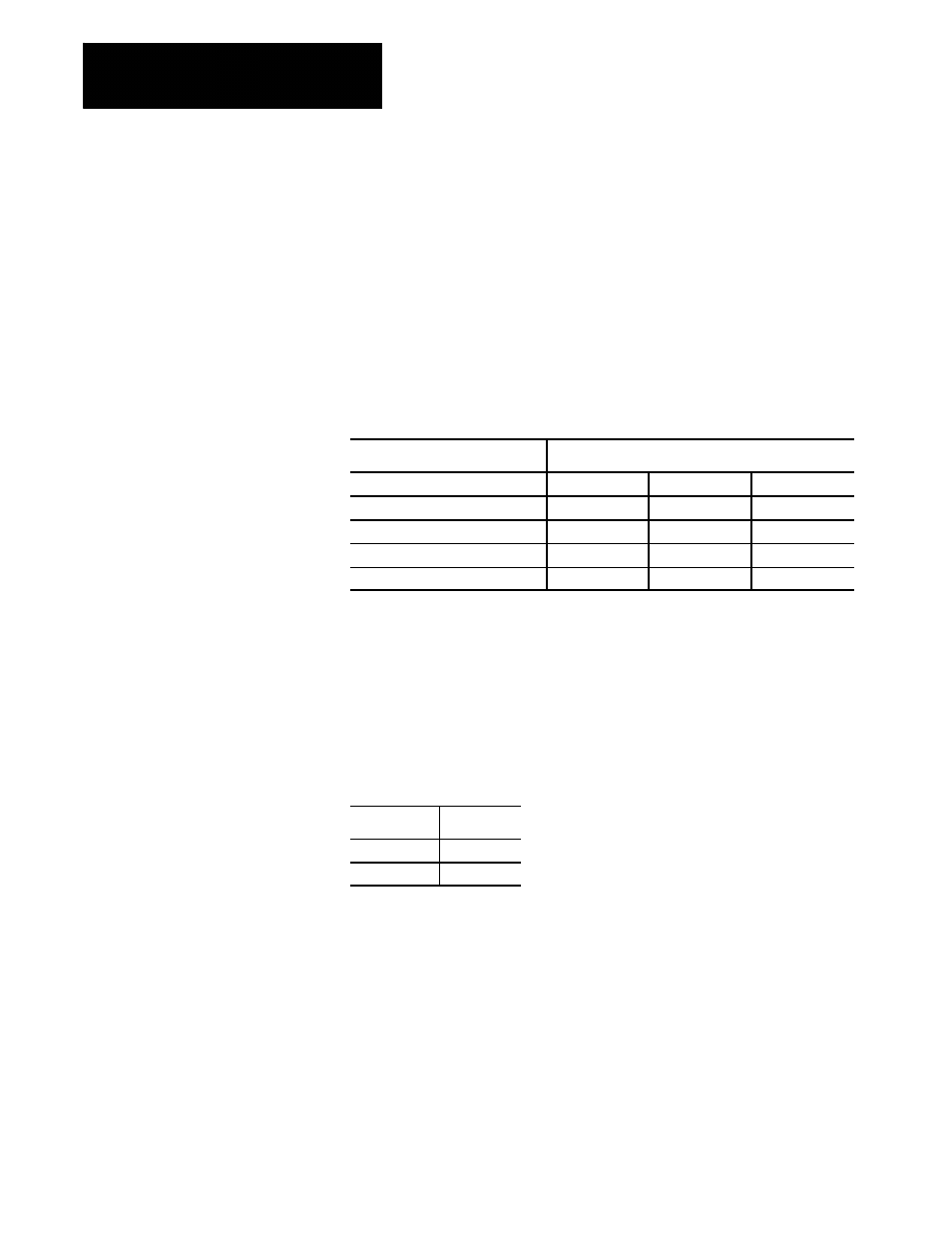

Parameter

Parameter Number

Single Process

Process 1

Process 2

Add to Tool Offset for Skip 1

[210]

[20210]

[21210]

Add to Tool Offset for Skip 2

[211]

[20211]

[21211]

Add to Tool Offset for Skip 3

[212]

[20212]

[21212]

Add to Tool Offset for Skip 4

[213]

[20213]

[21213]

True -- When this parameter is true, the value generated by the G37 cycle is

added to the offset data selected in the parameter Target Offset for Skip.

False -- When this parameter is false, the value generated by the G37 cycle

replaces the offset data in the table selected in the parameter Target Offset

for Skip.

Range

Selection

Results

(a)

True

(b)

False

Notes

These are global parameters; the value set here applies to all axes.

For Dual Processing controls, this is a per process parameter. The value set

in the parameters applies to all of the axes assigned to that process.

22.10

Add to Tool Offset for Skip

1 - 4