Servo parameters, 0 chapter overview, Chapter – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 147

Chapter

7

7-1

Servo Parameters

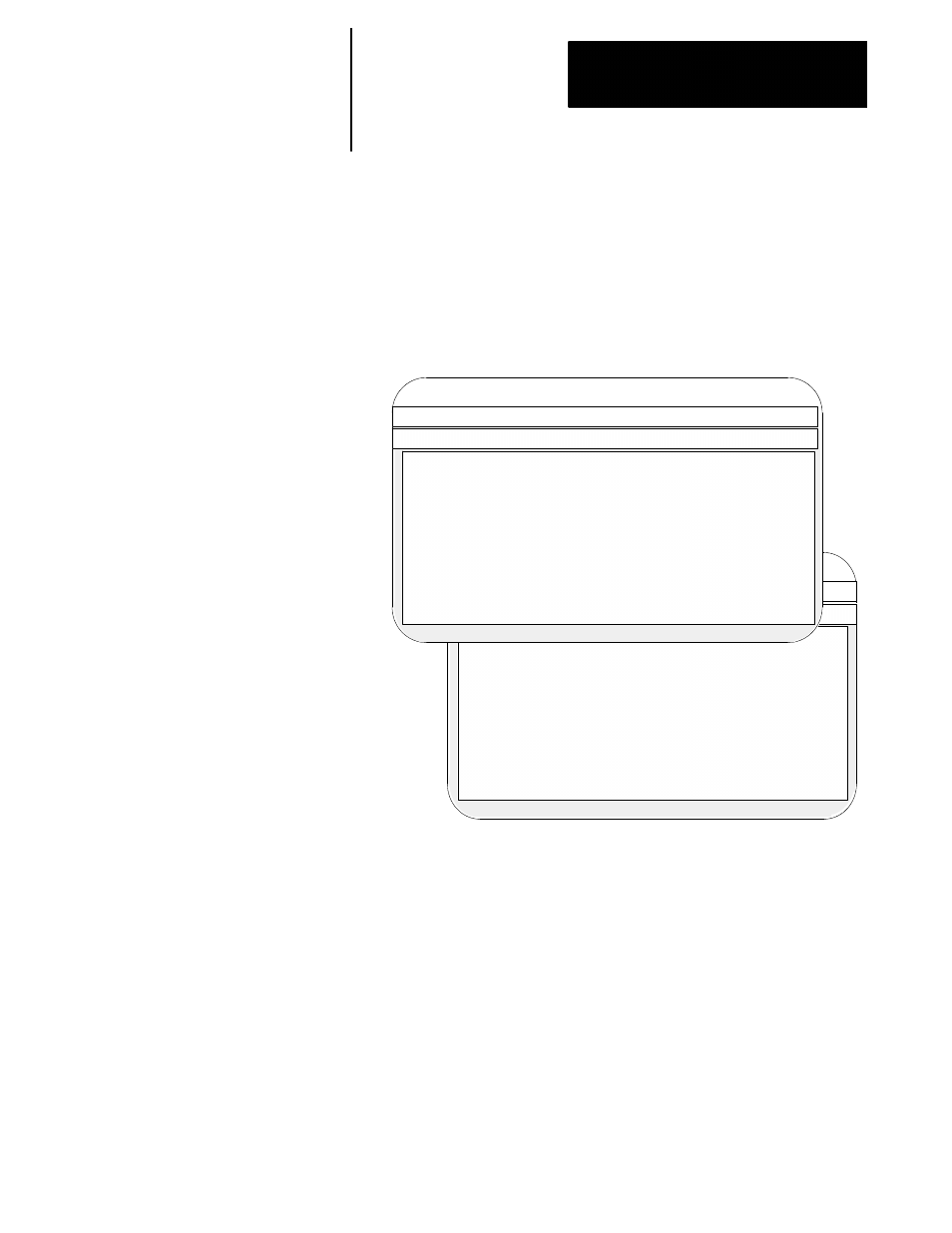

Use the servo parameter group to configure information about the servos

controlled by your 9/Series CNC. When you select the “Servo Parameters”

group, the following parameters are available to you:

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Control: Mill

AXIS :

X - linear

File :

TEST

- Servo Parameters -

Gain Break Point (1)

:

8.00000 in

Inposition Band (1)

:

0.00100 in

Initial Gain of Position Loop (1) :

1.00000

Position Loop Gain Break Ratio (1) :

1.00000

Feed Forward Percent (1)

:

0 %

Lead screw thread pitch (1)

:

0.100 in

Reversal Error Compensation (1)

:

0.00000 in

Excess Error (1)

:

8.00000 in

Feedrate Suppression Point (1)

:

8.00000 in

Velocity Loop Feedback Port (1)

:

No Feedback

Velocity Feedback Type (1)

: INC Encoder U/V/W on Dig. Mod.

Velocity Feedback Counts/Cycle (1) :

24000

Sign of Velocity Feedback (1)

:

Plus

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Control: Mill

AXIS :

X - linear

File :

TEST

- Servo Parameters -

Number of Motors on 1st Board

:

THREE

Num Motors 2nd Brd (9/260 - 290)

:

NONE

Standard Motor Table Values

:

yes

Servo Hardware Type (1)

:

9/440 Digital (1394)

Servo Loop Type (1)

:

Digital or Digital Spindle

Output Port Number (1)

:

No Output

Servo Position Loop Type (1)

:

Open Loop

Position Loop Feedback Port (1)

:

Optional Feedback Con J9 or CN14

Position Feedback Type (1)

:

A Quad B With One Marker

Position Feedback Counts/Cycle (1) :

24000

Sign of Position Feedback (1)

:

Plus

Teeth on gear for pos. FB (1)

:

1

Teeth on lead screw for pos FB (1) :

1

Page 1 of 4

Page 2 of 4

7.0

Chapter Overview