15 teeth on gear for position feedback – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 200

Servo Parameters

Chapter 7

7-54

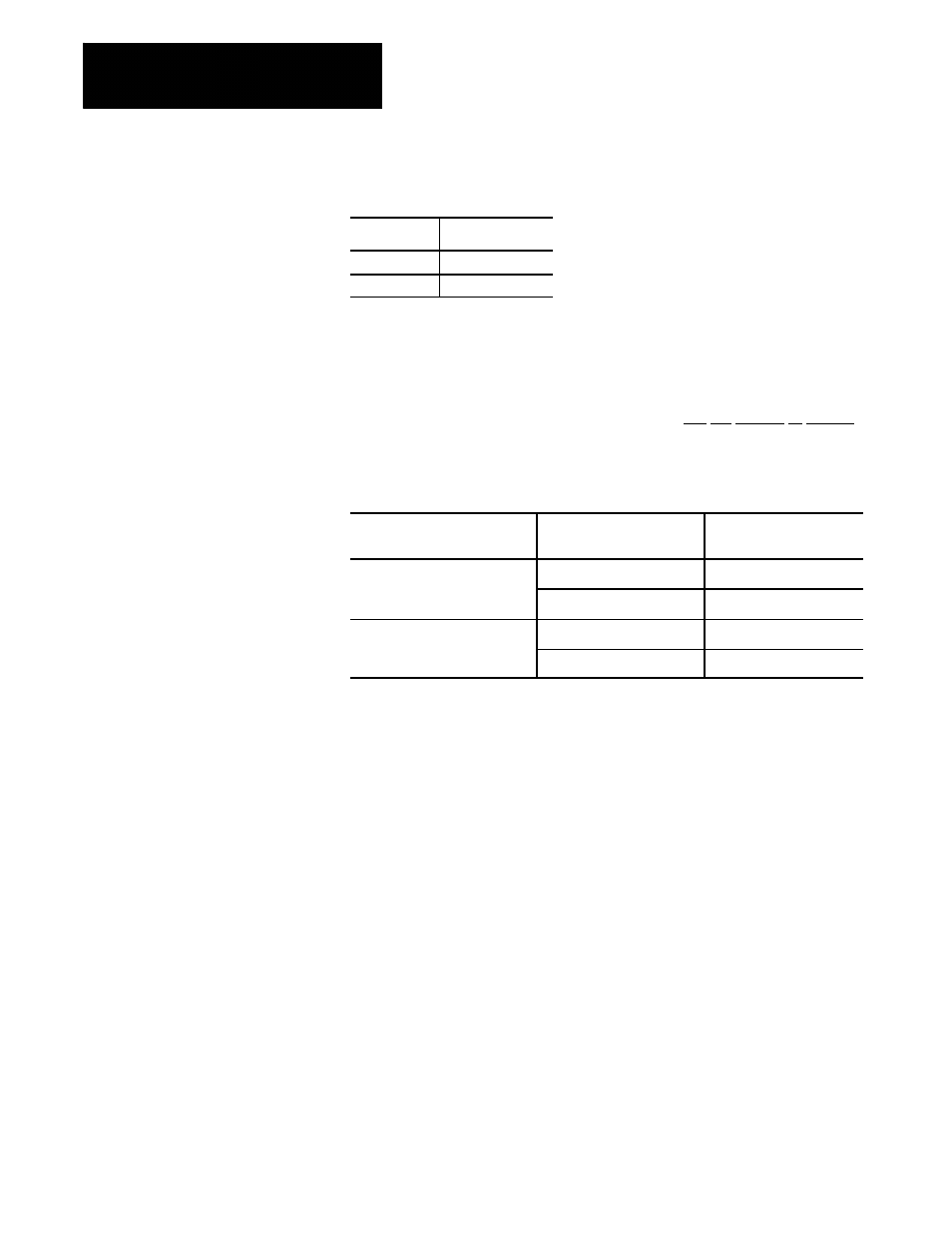

Range

Selection

Result

(a)

Plus

(b)

Minus

Notes

This parameter must be set independently for each servo.

After installing and wiring the feedback device, put the control in E-Stop,

and set the axis display to monitor feedback. Manually rotate the

feedback device, noting axis direction and whether the feedback is

counting negative or positive.

If the axis is moving in the

direction defined as:

and if the feedback is

counting:

then, for the Sign of

Position Feedback, enter:

positive

up

PLUS

down

MINUS

negative

down

PLUS

up

MINUS

Function

If you are using the same physical device for both the velocity loop and

position loops, then the value entered for this parameter should be the same

as the value entered for the parameter Teeth on Lead Screw for Vel FB.

If you are using a nonmotor--mounted position feedback device (connected

to a separate feedback port than the velocity feedback), enter the number of

teeth on the gear or gearbelt pulley attached to the feedback device. This

number is used in conjunction with the parameter Teeth on Lead Screw

for Pos FB to calculate the gear ratio from the position feedback device to

the lead screw (number of lead screw revolutions that occur between

position feedback device revolutions). The control then uses this ratio

combined with the entered Lead Screw Thread Pitch and Position

Feedback Counts/Cycle to determine the number of feedback counts that

occur per revolution of the lead screw.

Important: If configuring a linear position feedback device (excluding

distance--coded marker systems) use the parameters Position Feedback

Counts/Cycle and Lead Screw Thread Pitch to enter the number of

counts returned by the device per revolution of the lead screw. The ratio

7.2.15

Teeth on Gear for

Position Feedback