18 torque filter cutoff frequency – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 232

Servo Parameters

Chapter 7

7-86

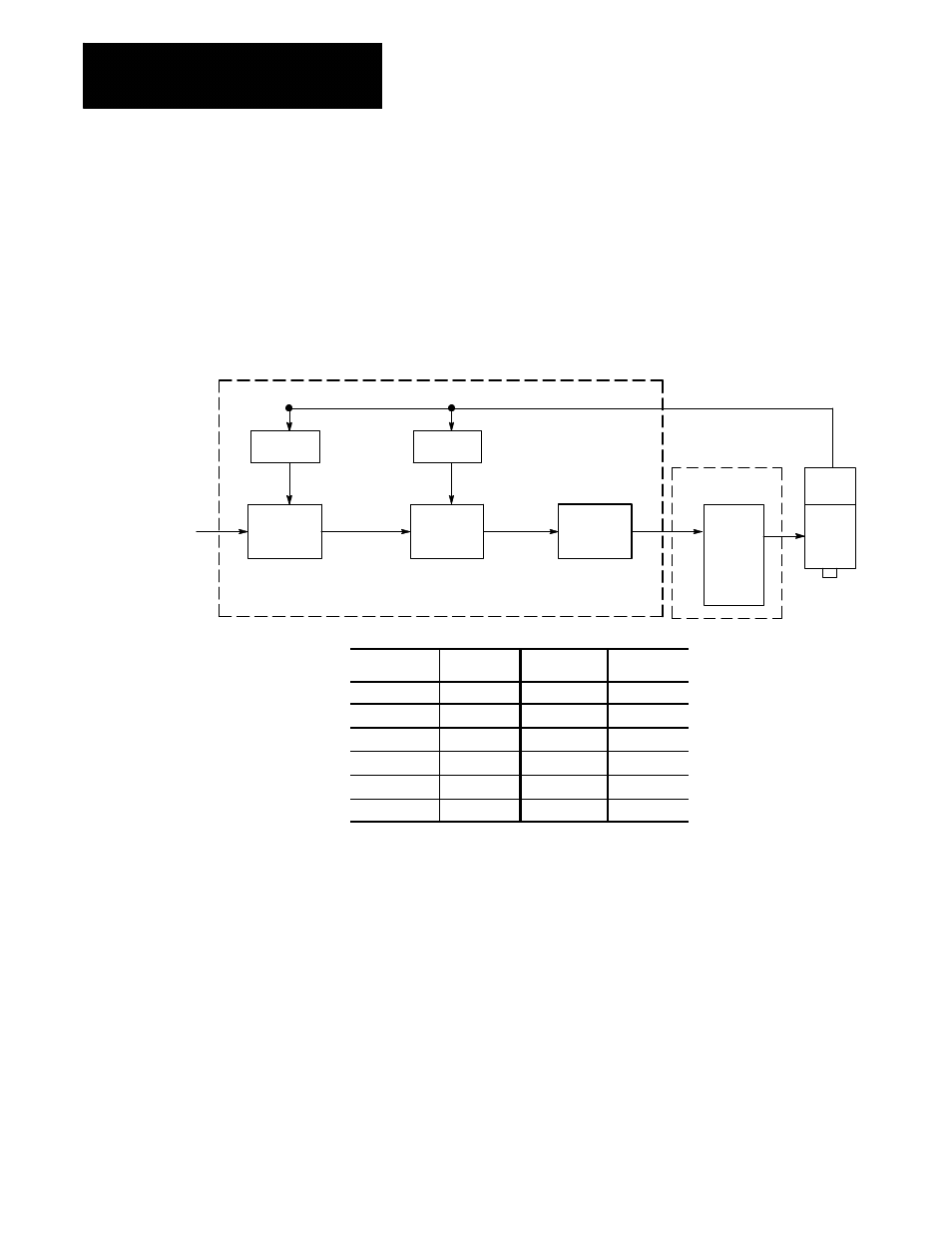

Function

This parameter is used on all digital systems and on analog systems that

use the Tachless Software Velocity Loop feature (loop type digital or

position/velocity). This filter can be used to remove some oscillations that

can occur in your drive systems (typically caused by some mechanical

characteristic). If an oscillation exists (and you have eliminated other

possible tuning causes) set this torque filter to a point just below the

frequency (in Hz) at which the oscillation stops occurring.

Digital (or Position/Velocity) Servo Interface

Position

command

Power

amplifier

Feed-

back

Motor

Position

detection

Velocity

Loop

Servo

Amplifier

Torque

Command

Filter

Position

Feedback

Position

Loop

Velocity

cmd.

Torque

cmd.

Axis

Number

Axis

Number

(1)

[1162]

(7)

[7162]

(2)

[2162]

(8)

[8162]

(3)

[3162]

(9)

[9162]

(4)

[4162]

(10)

[10162]

(5)

[5162]

(11)

[11162]

(6)

[6162]

(12)

[12162]

Range

10 to 10000 Hz

Notes

This parameter must be set independently for each servo. The torque filter

can be disabled by setting this parameter as high as possible (10000 Hz)

and should be disabled during initial servo tuning.

If you have no method of identifying the frequency of the oscillation, use this

procedure to set the torque filter cutoff frequency. First disable this filter by

raising the cutoff frequency to a very high number (2000 or 3000). Then

keep lowering the cutoff frequency until the oscillation stops occurring.

7.3.18

Torque Filter

Cutoff Frequency