4 maximum tool offset number – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 477

Tool Offset Parameters

Chapter 22

22-5

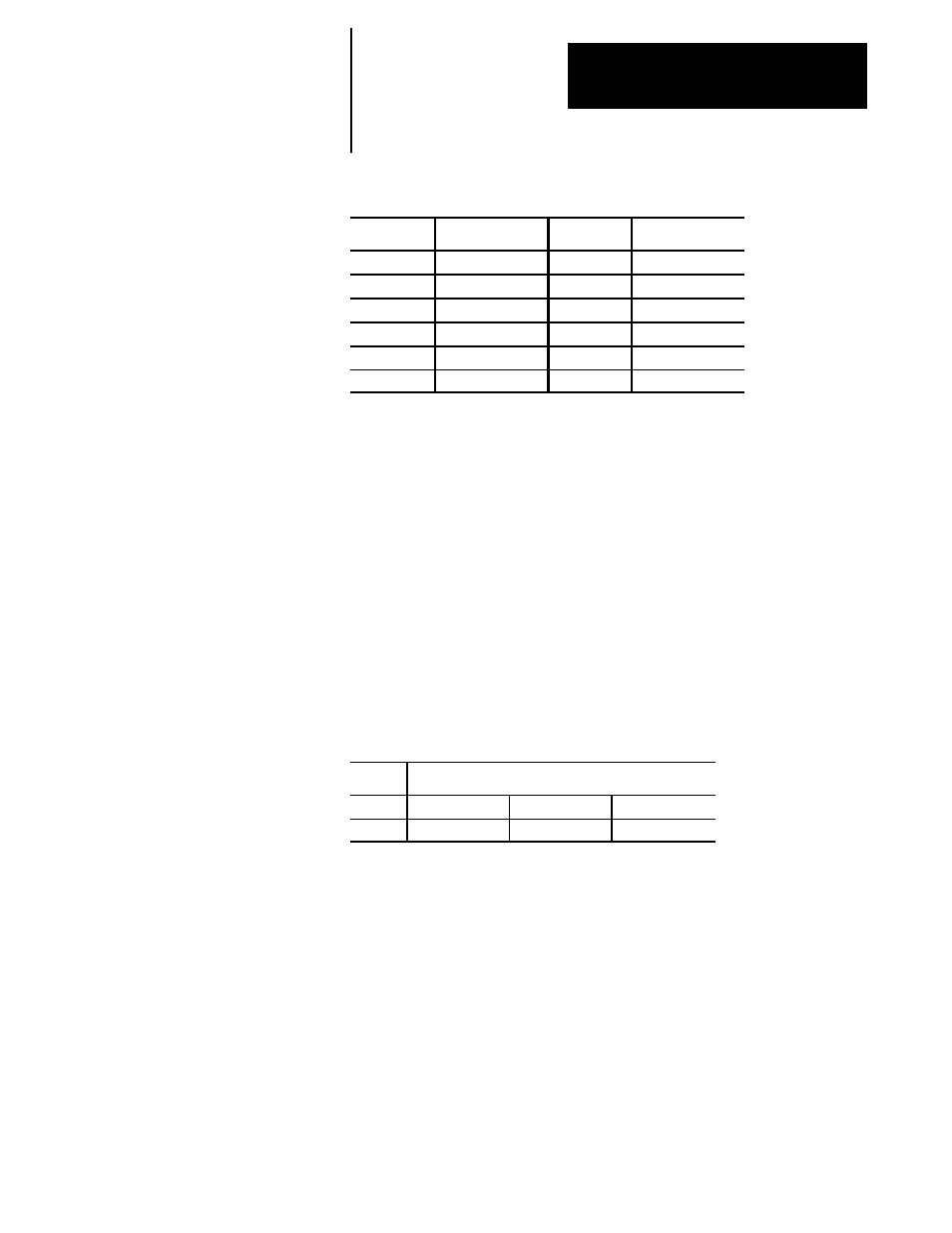

Range

Selection

Results

Selection

Results

(a)

Axis 1

(g)

Axis 7

(b)

Axis 2

(h)

Axis 8

(c)

Axis 3

(i)

Axis 9

(d)

Axis 4

(j)

Axis 10

(e)

Axis 5

(k)

Axis 11

(f)

Axis 6

(l)

Axis 12

Notes

The part programer can temporarily override the axis selected here by

programming a G43.1. Refer to your programming and operation manual

for more information.

This is a global parameter; the value set here applies to all axes. For Dual

Processing controls, this is a per process parameter. The value set in the

parameters applies to all of the axes assigned to that process.

Function

Use this parameter to determine the maximum number of tool offsets that

may be entered in the tool offset tables. Any program that calls an offset

number greater than this parameter generates an error or may be used as a

tool life group number. The control does not allow the entry of a tool

offset number in the offset tables that is greater than this parameter.

Axis

Parameter Number

Single Process

Process 1

Process 2

All

[201]

[20201]

[21201]

Range

40 to 200 tool offsets in lathe or mill applications

1 to 32 tool offsets in grinder applications

Notes

This is a global parameter; the value set here applies to all axes. For Dual

Processing controls, this is a per process parameter. The value set in the

parameters applies to all of the axes assigned to that process.

22.4

Maximum Tool Offset

Number