Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 163

Servo Parameters

Chapter 7

7-17

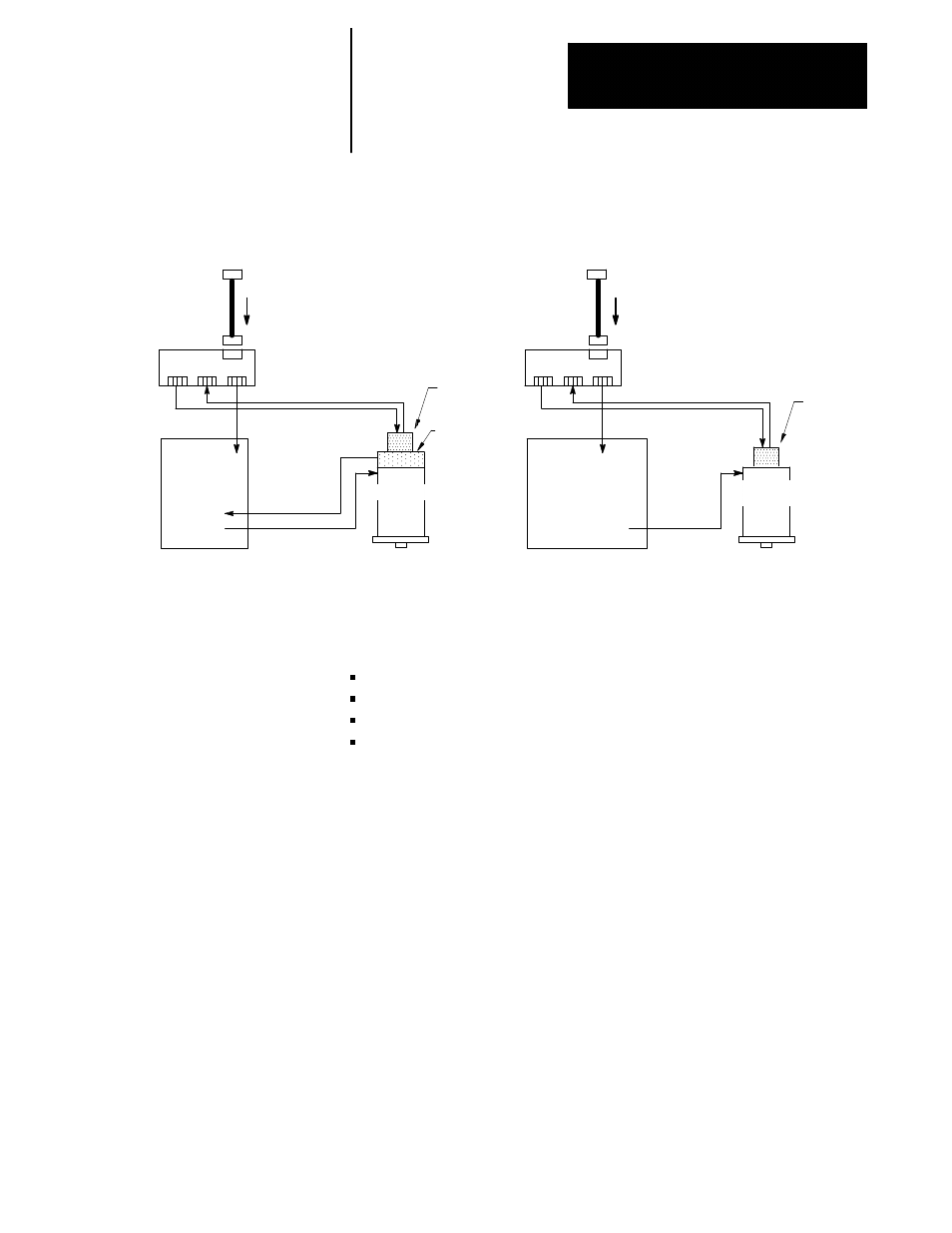

Figure 7.6

Tachometer vs. Tachless Velocity Loop

Position feedback

Encoder power

Velocity

Feedback

Servo

Amplifier

External Hardware Tach Loop

Servo Loop Type = (b) Position (Analog with Tach)

Tachless Software Velocity Loop

Servo Loop Type = (b) Position/Velocity (Tachless)

Servo Connection on Control

Term Panel

Encoder

Tachometer

(also used for velocity loop)

Encoder power

Servo

Amplifier

Servomotor

Term Panel

Encoder

Position feedback

Servo Connection on Control

Servomotor

(set as Torque Mode)

Position Command

Torque Command

Important: When a tachless analog systems detects an E-stop condition,

the control sets the torque output command to zero. You need to reduce the

motor speed to zero in a safe manner. This can be done through one of

these methods:

Torque Amplifier Dynamic Braking

Resistor Type Dynamic Braking

Setting a Motor Brake

User-defined braking

The customer-supplied torque-block amplifier is responsible for both short

and long term thermal protection of the amplifier and motor.

The torque command is limited at

±

10 volts. You need to scale the peak

motor current to this limit.

The parameter ACC/DEC RAMP may need to be set to control the speed

torque envelope.

This block diagram illustrates tachless operation when the control is in

ZFE (zero following error) mode.