Fixed cycles chapter 25 – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 522

Fixed Cycles

Chapter 25

25-2

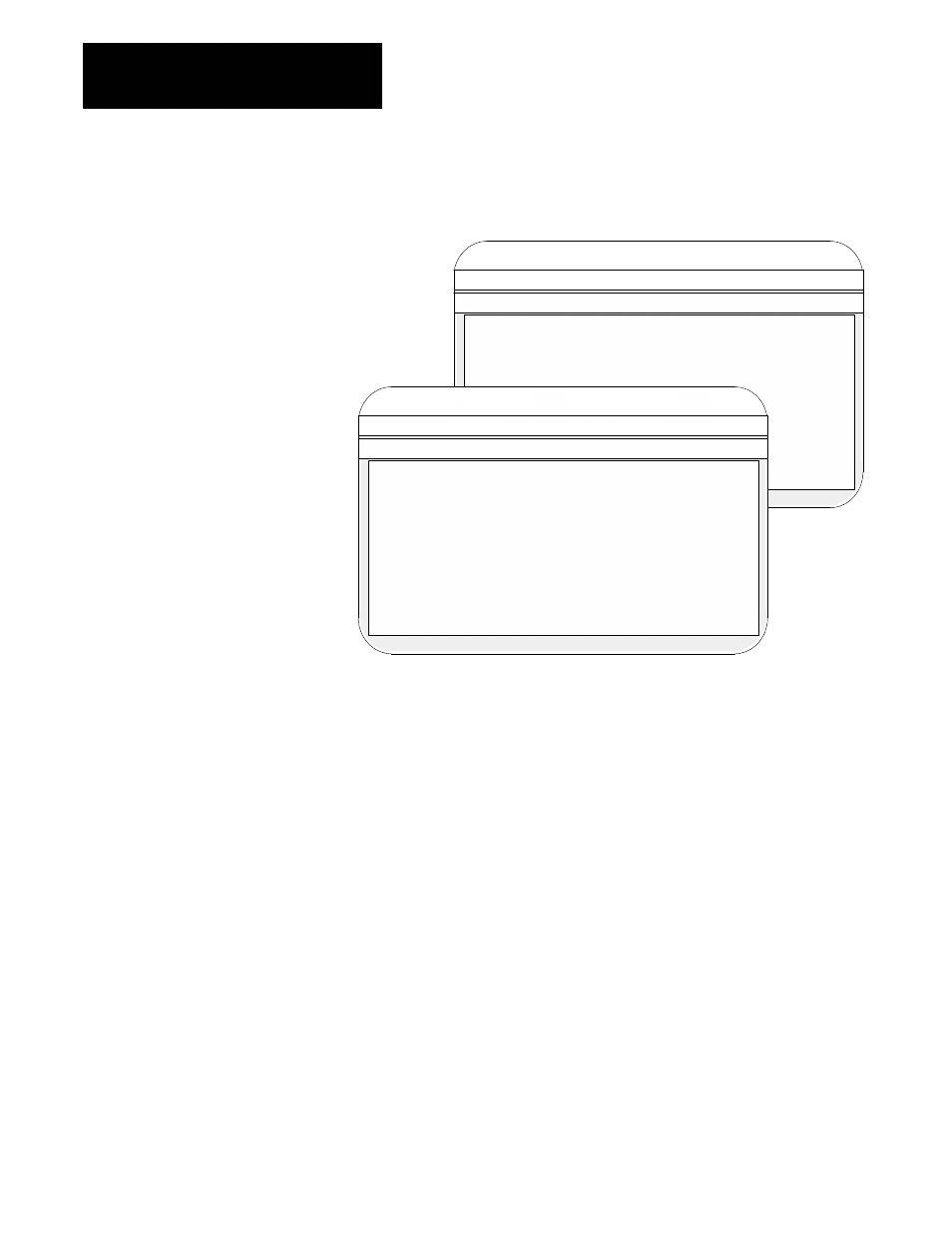

When you select control type “Mill,” the workstation displays these

screens:

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

- Fixed Cycle Parameters -

Page 2 of 2

Proj:

AMPTEST

Appl:

AMP

Util:

Edit

F2-Project F3-Application F4-Utility

F5-Configuration

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Type : Mill

Axis: X

P1:

File :

TEST

- Fixed Cycle Parameters -

Page 1 of 2

Retract amount - Peck Drilling

25.40000 mm

Fine boring shift in Q-word

:

yes

Pullout angle, chamfered thrd

:

5.0 degrees

Pullout dist, chamfered thrd

:

5.080 Thread leads

Cycle clearance amount

:

25.40000 mm

Fine Boring shift dir. G17

:

G17 Primary axis 2 positive

Fine Boring shift dir. G18

:

G18 Primary axis 2 positive

Fine Boring shift dir. G19

:

G19 Primary axis 2 positive

Ignore dwell in tapping cycles

:

no

Rapid to Drilling Hole

:

yes

Always Repeat Turning Cycles

:

no

Fixed drilling axis

:

axis 3

Dwell time for G82, G88 & G89

:

2.00000 seconds

Dwell time for G84 & G86

:

0.20000 seconds

Forward drill time (T1) for G83

:

2.00000 seconds

Retract time (T2) for G83

:

1.00000 seconds

F1-File

F2-Axis

F3-Options

F4-Quick Edit!

F5-Process

Type : Mill

Axis: X

P1:

File :

TEST

These parameters cannot be used for grinder applications. Grinder fixed

cycles parameters can be found in the Angled-Wheel parameter group and

the Miscellaneous Parameter group.