A.4 create your tuning part program – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 732

Tuning a Digital or Tachless Analog System

Appendix A

A-10

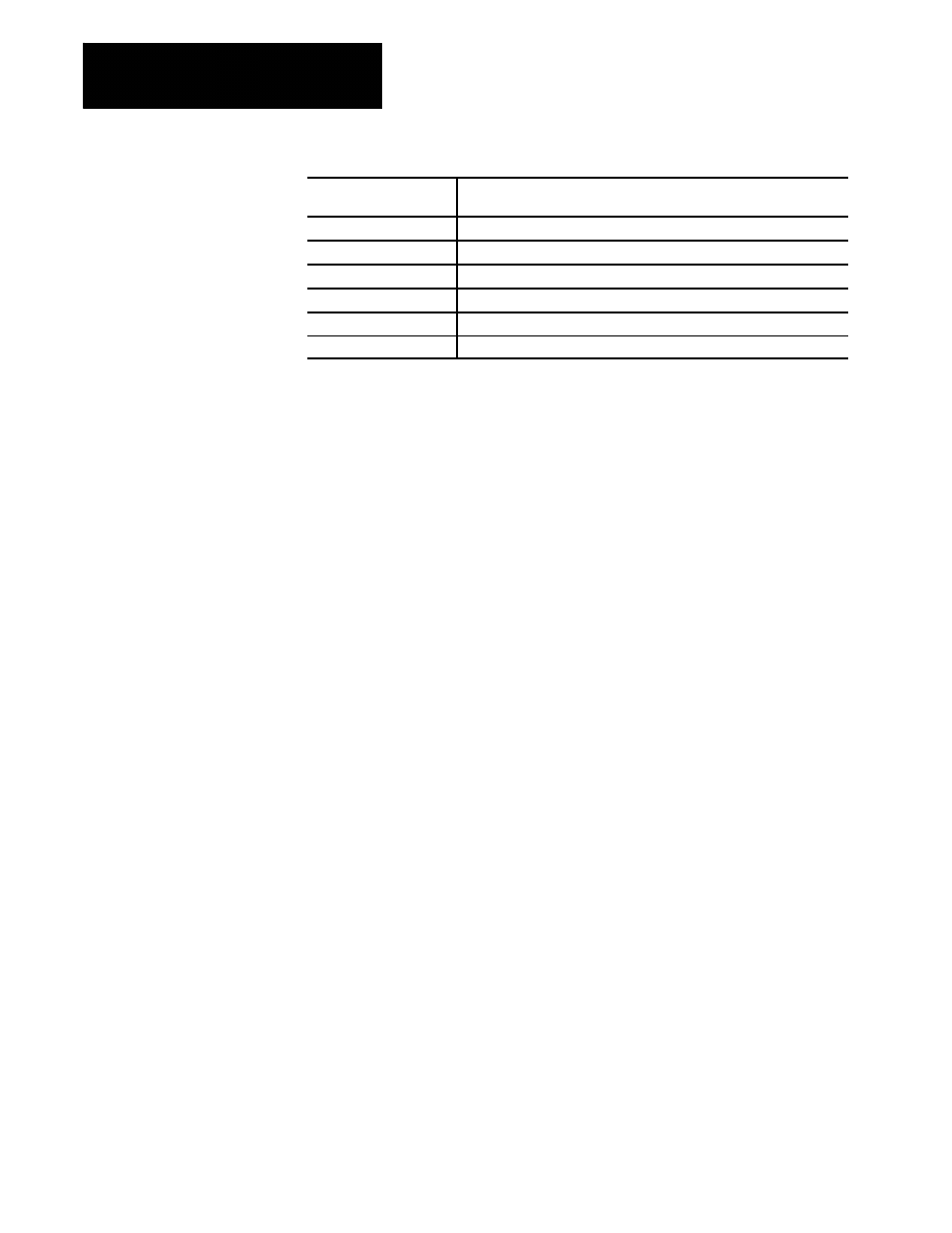

30

Course Iteration Incremental Position Command for the 6th Servo on the

servo card (typically the spindle)

31

Interpolated Final Velocity command for the 1st Servo on the servo card

32

Interpolated Final Velocity command for the 2nd Servo on the servo card

33

Interpolated Final Velocity command for the 3rd Servo on the servo card

34

Interpolated Final Velocity command for the 4th Servo on the servo card

35

Interpolated Final Velocity command for the 5th Servo on the servo card

36

Interpolated Final Velocity command for the 6th Servo on the servo card

For our tuning procedure we will only be using the velocity feedback

values.

Use Patch AMP to turn on the DAC monitor for the axis you are going to

tune. For example, if you are going to tune the first axis on the first servo

card you would set #86 = 5 (for 3 axis servo cards or 9/230 controls) or

#86 =1 (for 4 axis servo cards or 9/440 controls). If you are going to tune

the second axis on the third servo card you would set #133 = 6 (3 axis

servo cards) or #133 = 2 (for 4 axis servo cards). 9/230 CNCs only use

#86. 9/440 CNCs only use #86 and #87.

When you press the update and exit softkey in patch AMP, the control will

ask you to cycle power. Once you turn power back on, the control will

display a message indicating the DAC monitor has been enabled, what it is

monitoring, and the axis name being monitored.

A tuning part program is not necessary but can be helpful when tuning

your system. This part program should perform a repetitive move that

reverses direction in a repeating loop. The feedrate for this move should

be equal to your machine’s maximum cutting feedrate. Refer to your

9/Series operation and programming manual for details on creating a part

program.

The example part program below repeats its moves 6 times using

paramacro looping. If your system does not have paramacros, just

repeating the same motion blocks will have the same effect. This example

assumes that the servo being tuned positions the X axis and that the

maximum cutting feedrate is 1000 IPM. You may need to adjust the axis

name, range of motion, and feedrate in this example for your application.

A.4

Create your Tuning Part

Program