2 feed proportional torque gain – Rockwell Automation 8520-ARM2 9/Series CNC AMP Reference Manual Documentation Set User Manual

Page 589

Adaptive Feed & Depth Parameters

Chapter 32

32-3

Function

This parameter specifies the proportional torque gain for an axis move that

is performed in adaptive feed mode. Refer to your 9/Series Mill Operation

and Programming Manual for details on this feature. This parameter is

only available on mill control types.

This parameter (in conjunction with the parameter Feed Integral Torque

Gain) is used to determine the net change to the 9/Series feedrate

command. The feedrate is modified in order to try to maintain a constant

torque. The desired torque is specified in the G25 program block.

This parameter specifies the ratio of % change in feedrate to the

instantaneous torque error. When you increase the value of the Feed

Proportional Torque Gain, it will cause the instantaneous torque error to

have a greater effect on the adaptive feedrate. This parameter is typically

less than the Feed Integral Torque Gain parameter.

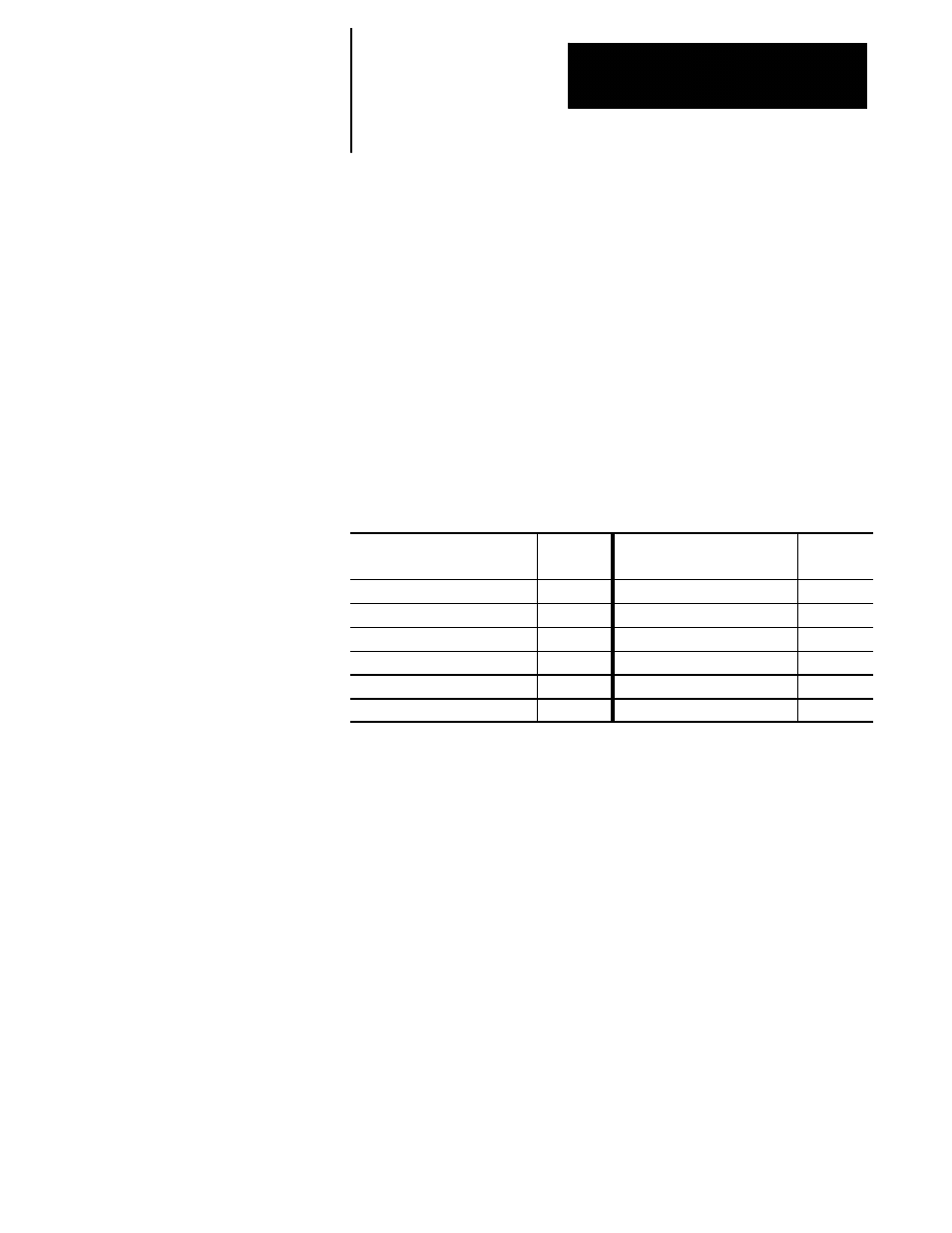

Feed Proportional Torque Gain

Axis number

Parameter

Number

Feed Proportional Torque Gain

Axis number

Parameter

Number

Axis (1)

[1153]

Axis (7)

[7153]

Axis (2)

[2153]

Axis (8)

[8153]

Axis (3)

[3153]

Axis (9)

[9153]

Axis (4)

[4153]

Axis (10)

[10153]

Axis (5)

[5153]

Axis (11)

[11153]

Axis (6)

[6153]

Axis (12)

[12153]

Range

0.1 to 2.0

Notes

This parameter must be set independently for each axis.

The adaptive feed mode can be programmed on any closed loop axis

except an axis that positions more than one servo (such as dual or deskew

axes).

If you are going to use the adaptive feed feature on an analog system the

system must be configured to run in tachless operation. See page 7-15 for

details on configuring a tachless velocity loop on an analog system.

32.2

Feed Proportional

Torque Gain