Example 4: wet well operation – Rockwell Automation 21G PowerFlex 750-Series AC Drives Programming Manual User Manual

Page 496

496

Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Appendix C

Using DeviceLogix

Example 4: Wet Well Operation

This example demonstrates how basic control logic can be used for simple

applications. It is assumed that the PowerFlex 755 has an I/O module installed in

Port 4.

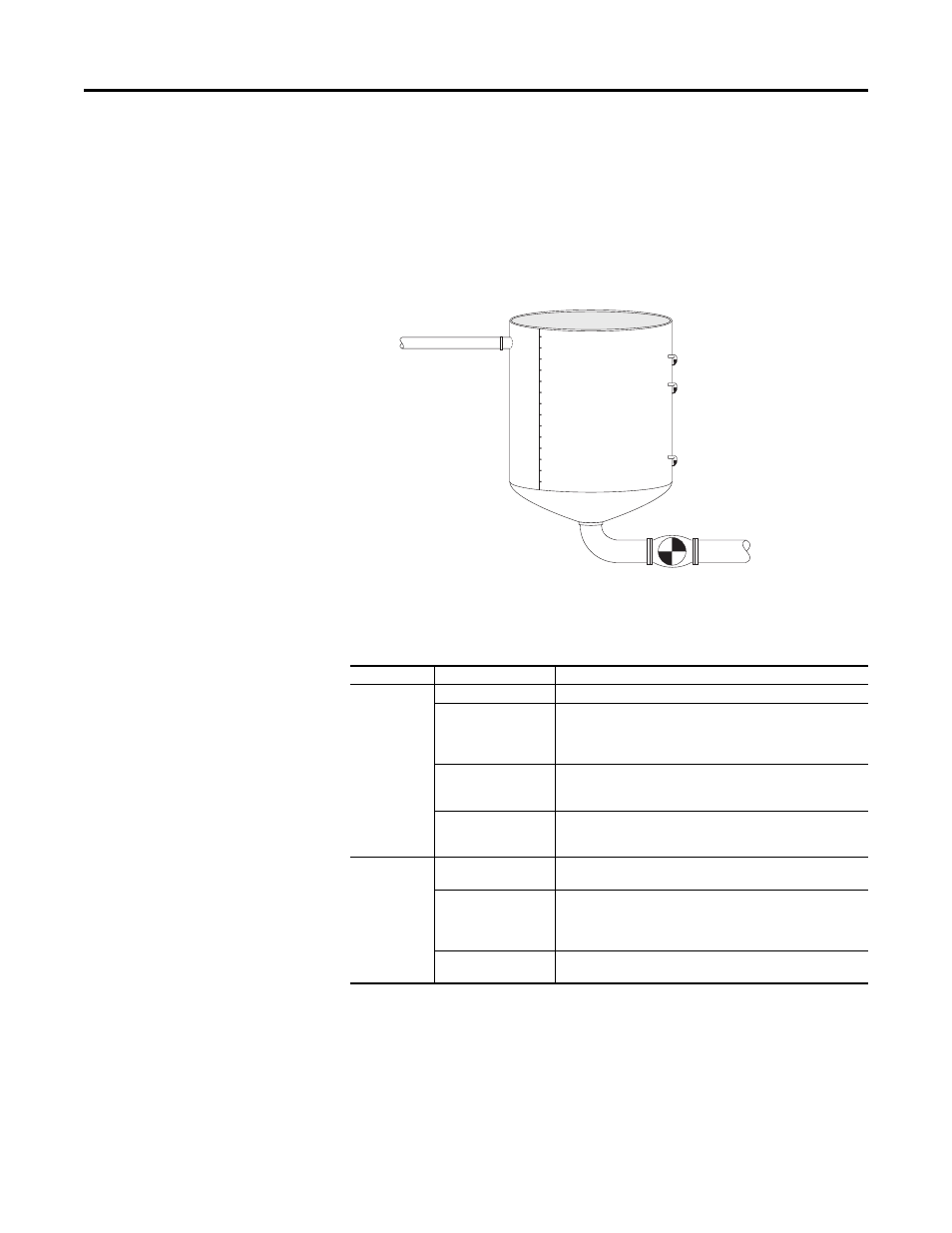

Figure 91 - Wet Well

The application consists of the following discrete I/O:

Type

Name

Description

Inputs

Fault Reset pushbutton

Used to reset any faults or alarms

Critical High Level sensor

Indicates a critically high level. It is normally a backup to the High Level

sensor and is also used to detect if the High Level sensor is faulty. When

ON, the drive will operate at an even higher output frequency in case it

is due to a high inflow.

High Level sensor

Indicates the well is at a high level and it is time to start pumping

(normal operation). The drive operates at a ‘normal’ rate unless the

Critical High Level was reached.

Low Level sensor

When OFF, it is used to indicate that the well is empty (as long as the

High and Critical High Level sensors are also OFF). The drive stops

operating (end of pumping cycle).

Outputs

Sensor Fault pilot light

Indicates that there is a problem with either the High Level or Low Level

sensors

Too Much Time Alarm pilot

light

If the drive operates for more than the normal amount of time it takes to

empty the well, there may be increased inflow or perhaps the Low Level

sensor is stuck ON. An alarm indication is made and the drive continues

to operate.

Critical High Fault flashing

light / alarm horn

Indicates a critically high level that requires immediate attention.

Outflow

Inflow

Critical High Level Sensor

High Level Sensor

Low Level Sensor