Example 3: diverter operation, Parameter configuration, Functional block programming – Rockwell Automation 21G PowerFlex 750-Series AC Drives Programming Manual User Manual

Page 495

Rockwell Automation Publication 750-PM001J-EN-P - October 2014

495

Using DeviceLogix

Appendix C

Example 3: Diverter Operation

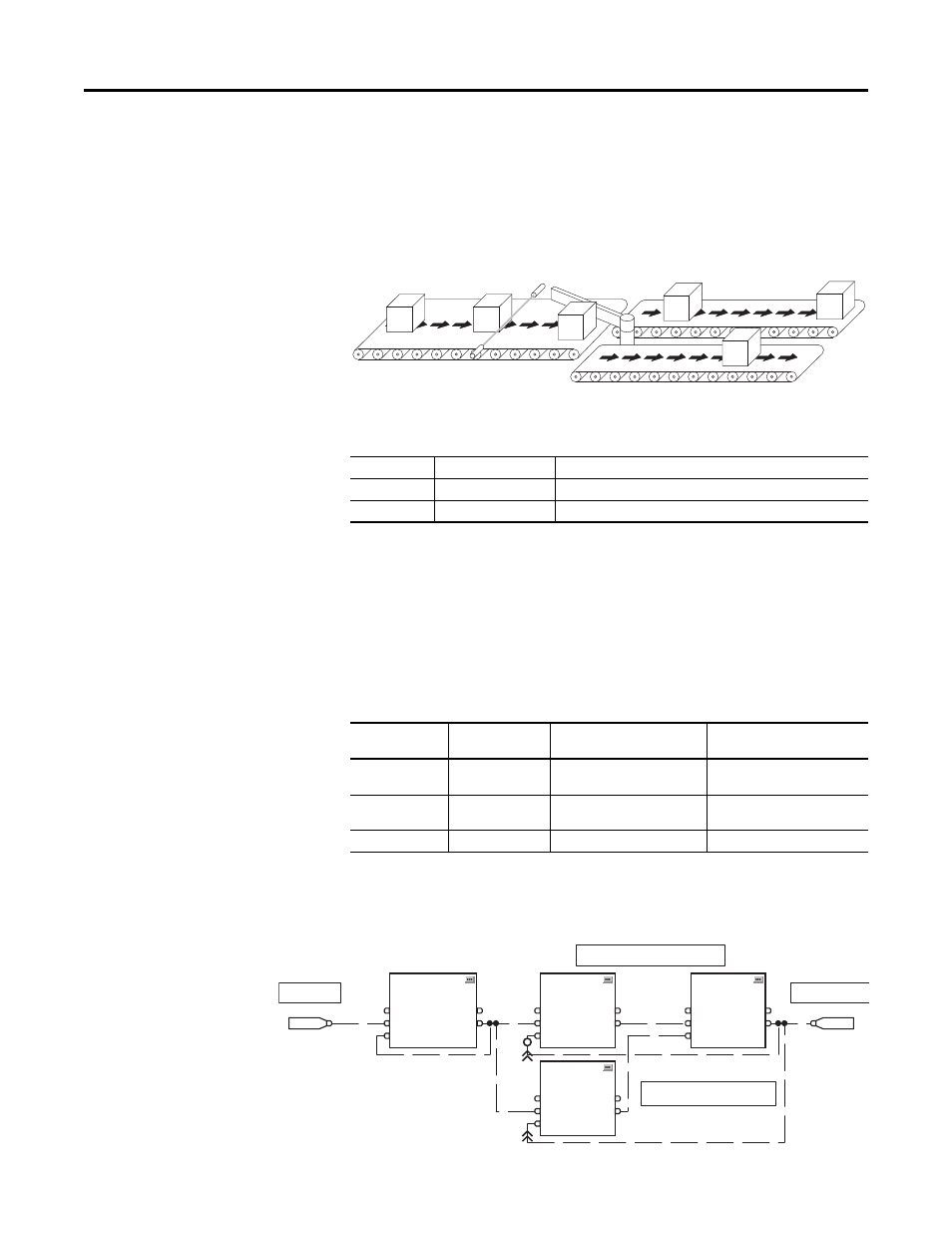

This example demonstrates basic control logic to operate a diverter in a conveyor

system. The diverter directs parts from an upstream conveyor to one of two

downstream conveyors. It alternately sends ‘x’ parts down each downstream

conveyor.

The application consists of the following discrete I/O:

Example logic requirements:

·

If Part Present Sensor is ON, then increment the parts counter

·

If parts counter preset is reached, reset the counter and alternately set or reset

the Diverter Actuator

Parameter Configuration

The following parameters are configured for this example:

Functional Block Programming

This example consists of 4 blocks that are shown in the following figure.

Type

Name

Description

Inputs

Part Present Sensor

Identifies that a part is present

Outputs

Diverter Actuator

Controls the diverter actuator to direct the flow of parts

Port Parameter

No.

Parameter

Value

Description

4.20

TO0 Select

Port 14: DLX DigOut Sts2.DLX

DOPSts0

Output on I/O module in Port 4

14.33

DLX DIP 1

Port 4: Dig In Status.Input 1

Part Present Sensor input

(I/O module in Port 4)

14.51

DLX DigOut Sts2

Diverter Actuator output

Upstream Conveyor

Downstream Conveyor

Sensor

Diverter

DIP 1

0

Parts Counter

1 CTU

Count Up

EnableIn

CUEnable

Reset

1

0

DOP 1

0

Part Present

Photoeye

Output to control

the diverter

Flip-Flop circuit

1st time ON / 2nd time OFF on so on

Because loop-back is performed,

">>" is used to determine order

2 BAND

Boolean And

EnableIn

In1

In2

1

0

4 SETD

Set Dominant

EnableIn

Set

Reset

1

0

3 BAND

Boolean And

EnableIn

In1

In2

1

0