Rockwell Automation 21G PowerFlex 750-Series AC Drives Programming Manual User Manual

Page 473

Rockwell Automation Publication 750-PM001J-EN-P - October 2014

473

Application Notes

Appendix B

Execute Pump Off Action

When a Pump Off condition exists, the drive follows the setting of P1189

[Pump Off Action]. The process starts over at

in this sequence

allowing five strokes to allow the pump to settle out.

Whenever the operator changes the base speed command, the process starts over

at

in this sequence.

When P1187 [Pump Off Config] is set to 2 “Cycle,” the full stroke torque is used

for pump off detection. A separate position counter is enabled, which uses the

gear ratio and speed feedback to create a position. The gear ratio must be set

correctly for this action to work.

•

The position increments every 2 ms based on output frequency. The

torque is added to a buffer and a counter increments.

•

When the position counter reaches 10,000, the counter is reset to 0. The

torque buffer is divided by the counter to create the average torque for the

cycle.

•

This torque is the full cycle torque and is then used as the down stroke

torque was used in baseline set detection.

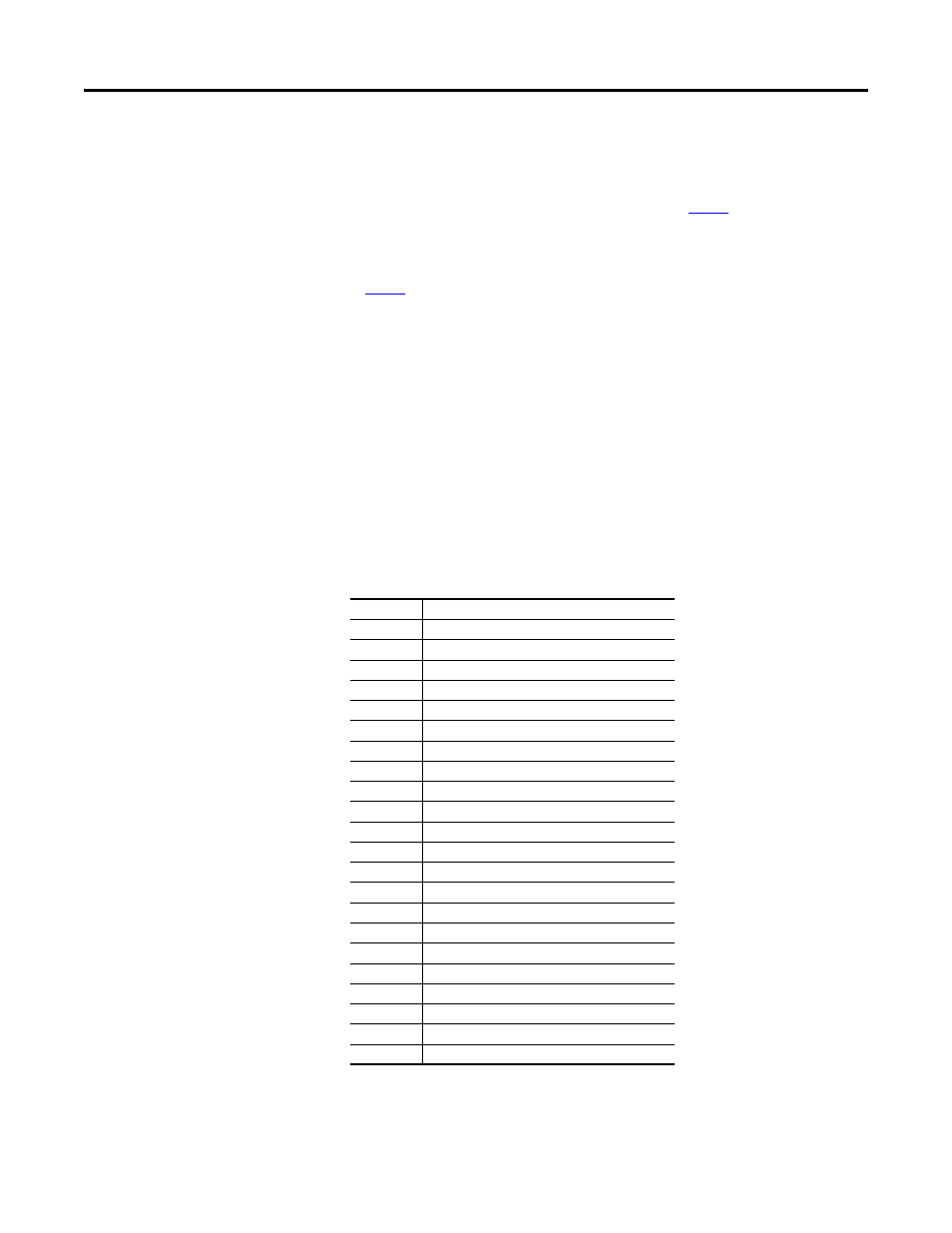

Table 1 - PowerFlex 753 Pump Off Test Points

Test Point

Description

TP 2031

Motor Torque in Pump Off

TP 2032

Top Of Stroke in Pump Off

TP 2033

POSITION1 in Pump Off

TP 2034

POSITION2 in Pump Off

TP 2035

POSITION3 in Pump Off

TP 2036

POSITION4 in Pump Off

TP 2037

POSITION5 in Pump Off

TP 2038

Active Position in Pump Off

TP 2039

Position State in Pump Off

TP 2040

Heavily filter torque for position detection in Pump Off

TP 2041

PumpJack control state in Pump Off

TP 2042

Avg Torque used for control state in Pump Off

TP 2043

Cycle count in Pump Off

TP 2044

Alarm count in Pump Off

TP 2045

Peak Torque in Pump Off

TP 2046

Offset Position in Pump Off

TP 2047

Simulator Torque Ref

TP 2048

Minimum Torque Position

TP 2049

Active Pump Off level

TP 2050

Down Stroke Torque Integrator

TP 2051

Full Stroke Position for cycle mode

TP 2052

Adjustment to Position indicator