Rockwell Automation 21G PowerFlex 750-Series AC Drives Programming Manual User Manual

Page 175

Rockwell Automation Publication 750-PM001J-EN-P - October 2014

175

Drive Port 0 Parameters

Chapter 3

Fil

e

Gr

ou

p

No.

Display Name

Full Name

Description

Values

Re

ad

-Write

Da

ta T

ype

APPLIC

AT

IONS

To

rq

ue

P

ro

ve

1100

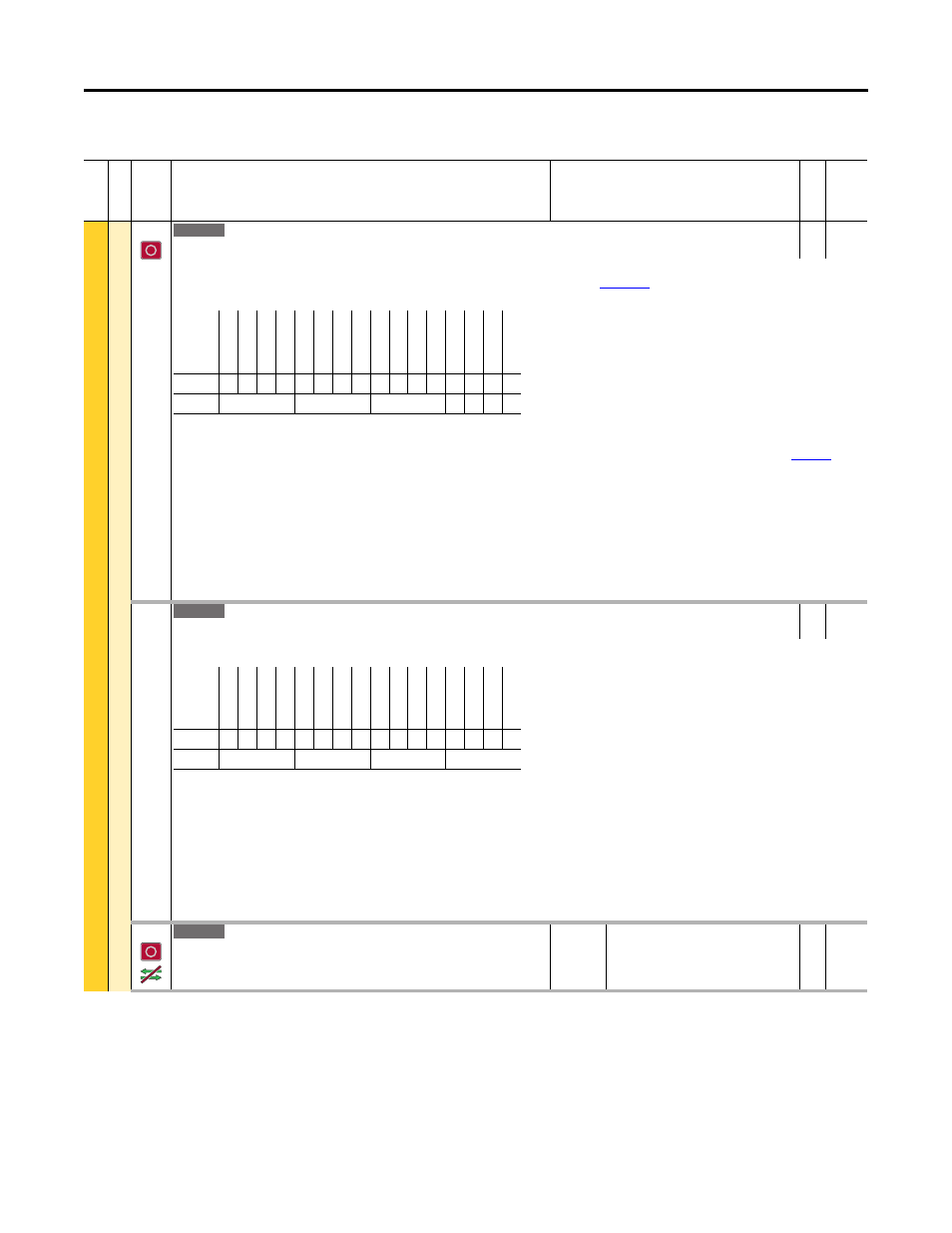

Trq Prove Cfg

Torque Prove Configure

RW 16-bit

Integer

Enables/disables torque/brake proving function. When “Enabled,” brake control comes from a digital output relay that is set to select Port 0, P1103 [Trq Prove

Status] Bit 4 “Brake Set.” Refer to the PowerFlex 750-Series AC Drives Reference Manual, publication

, for examples on how to use Torque Prove with

PowerFlex 755 drives.

Bit 0 “TP Enable” – Enables TorqProve functions.

Bit 1 “Encoderless” – Enables encoderless operation – Bit 0 must also be enabled. Read the Attention statement under Lifting/Torque Proving on

Bit 2 “Micro Psn” – Enables the Micro Position digital input to change the speed command by the value set in P1112 [MicroPsnScalePct] while the drive is running.

Bit 3 “Preload” – “0” uses the last torque for preload. “1” uses “TorqRef A” if commanded direction is forward and “TorqRef B” for reverse.

Bit 4 “FW LoadLimit” – Enables drive to perform load calculation at base speed. Drive will then limit operation above base speed depending on load.

Bit 5 “BrkSlipEncls” – A “1” Disables the partial Brake Slip routine from the drive when encoderless is selected.

Bit 6 “BrkSlipStart” – Starts drive if Brake slippage is detected.

Bit 7 “Test Brake” – Tests the brake at Start. Torque is applied against the brake while movement is monitored.

Bit 8 “Fast Stop Bk” – Brake is set immediately upon receiving a Fast Stop input vs. setting the brake after the ramp.

Bit 9 “BkSlp SpdLmt” – When a brake slip condition is detected, the load is lowered at a fixed speed (Preset Speed 1).

1101

Trq Prove Setup

Torque Prove Setup

RW 16-bit

Integer

Allows control of specific torque proving functions through a communication device.

Bit 0 “Fast Stop” – Forces a current limit stop.

Bit 1 “Float Micro” – Activates the micro position function when selected and running. Activates float when stopping.

Bit 2 “Decel Fwd” – Forces decel forward travel limit.

Bit 3 “End Stop Fwd” – Forces end forward travel limit.

Bit 4 “Decel Rev” – Forces decel reverse travel limit.

Bit 5 “End Stop Rev” – Forces end reverse travel limit.

Bit 6 “PHdwrOvrTrvl” – Positive Hardware Over Travel limit: Setting this bit creates a Coast to Stop fault.

Bit 7 “NHdwrOvrTrvl” – Negative Hardware Over Travel limit: Setting this bit creates a Coast to Stop fault.

1102

DI FloatMicroPsn

Digital Input Float Micro Position

Selects the digital input to be used for the float and micro position functions. Activates

the micro position function when selected and running. Activates float when stopping.

Default:

Min/Max:

0.00

0.00 / 159999.15

RW 32-bit

Integer

755

Options

Res

er

ved

Res

er

ved

Res

er

ved

Res

er

ved

Res

er

ved

Res

er

ved

Bk

Sl

p Spd

Lm

t

Fa

st

S

to

p B

k

Te

st

B

ra

ke

Br

kSli

pSta

rt

Br

kSli

pEncls

FW L

oadLimit

Pr

el

oad

Micr

o P

sn

En

cod

er

less

TP E

nable

Default

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Bit

15 14 13 12 11 10 9

8

7

6

5

4

3

2

1

0

0 = Disabled

1 = Enabled

755

Options

Res

er

ve

d

Res

er

ve

d

Res

er

ve

d

Res

er

ve

d

Res

er

ve

d

Res

er

ve

d

Res

er

ve

d

Res

er

ve

d

NHdwrO

vr

Tr

vl

PH

dwrO

vr

Tr

vl

En

d S

top

R

ev

De

ce

l R

ev

En

d S

top

Fw

d

De

ce

l F

w

d

Fl

oa

t M

ic

ro

Fa

st

S

to

p

Default

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Bit

15 14 13 12 11 10 9

8

7

6

5

4

3

2

1

0

0 = Disabled

1 = Enabled

755