5 measuring systems, Defining the system functionality – Lenze Engineer v2.21 User Manual

Page 194

Defining the system functionality

Creating an interconnection via the electrical shaft

194

Lenze · Engineer · 2.13 EN - 10/2014

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.14.5

Measuring systems

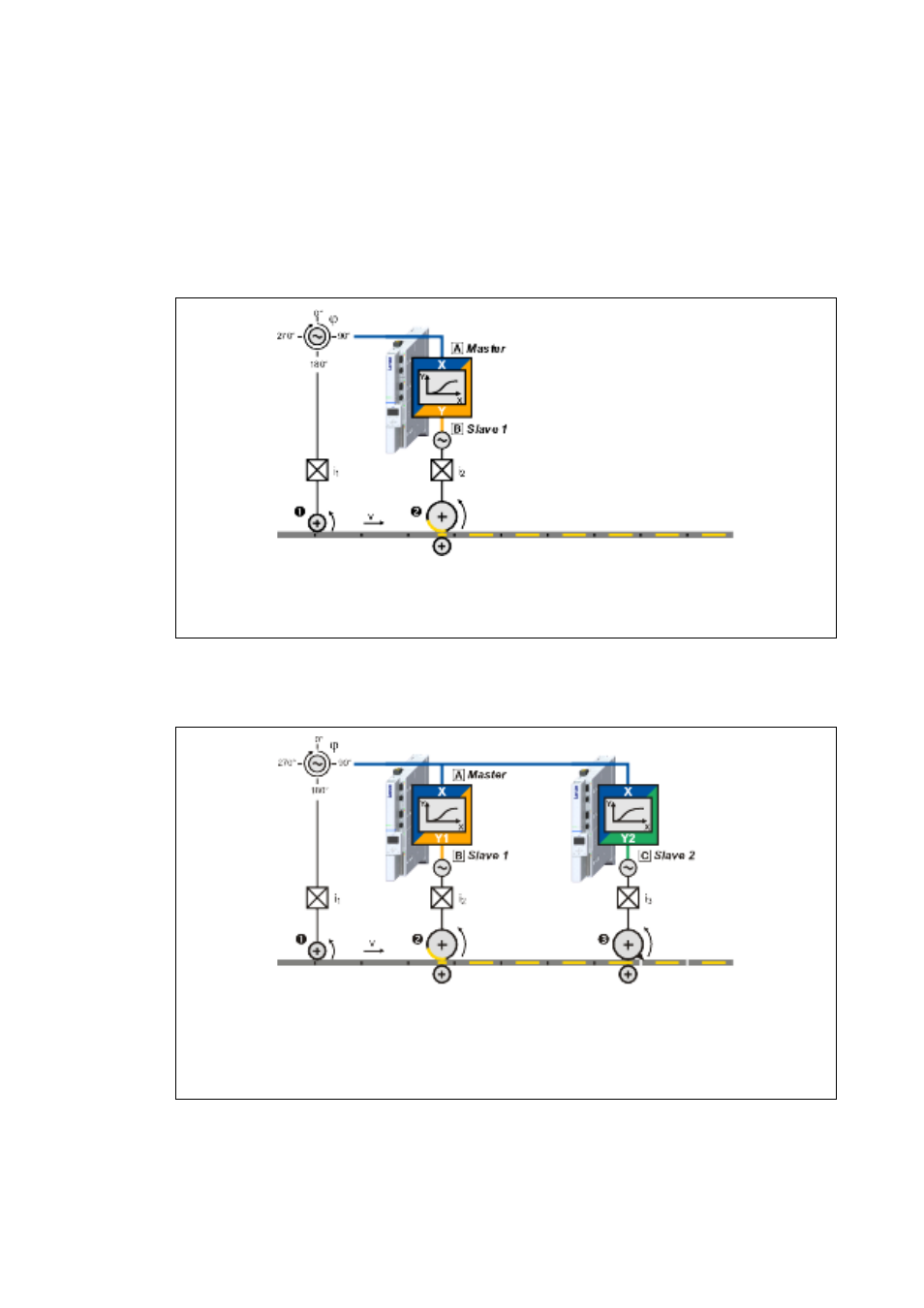

In a drive controller with a cam function, there are always at least two measuring systems: the

measuring system for stipulation of the master values (master) and the measuring system for the

drive axis (slave).

• The two measuring systems are merged with each other by means of the motion profile (curve),

with account being taken of the mechanical data (machine parameters).

[8-13] Example: Controller with cam function and two different measuring systems

• If several drive controllers are interconnected, other measuring systems are added in

accordance with the number of drive axes:

[8-14] Example: Controller interconnection with cam function and three different measuring systems

Master measuring system

Measuring system, slave 1

Encoder for the master value selection (real master)

Drive axis (slave 1)

Master measuring system

Measuring system, slave 1

Measuring system, slave 3

Encoder for the master value selection (real master)

Drive axis 1 (slave 1)

Drive axis 2 (slave 2)