2 synchronisation of the tools with a material, Defining the system functionality – Lenze Engineer v2.21 User Manual

Page 184

Defining the system functionality

Creating an interconnection via the electrical shaft

184

Lenze · Engineer · 2.13 EN - 10/2014

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.14.2

Synchronisation of the tools with a material

In the case of this relative coupling, the tools are not synchronised with each other but with the

material path (e.g. by means of a touch probe sensor). Therefore in such applications, a master

speed is needed.

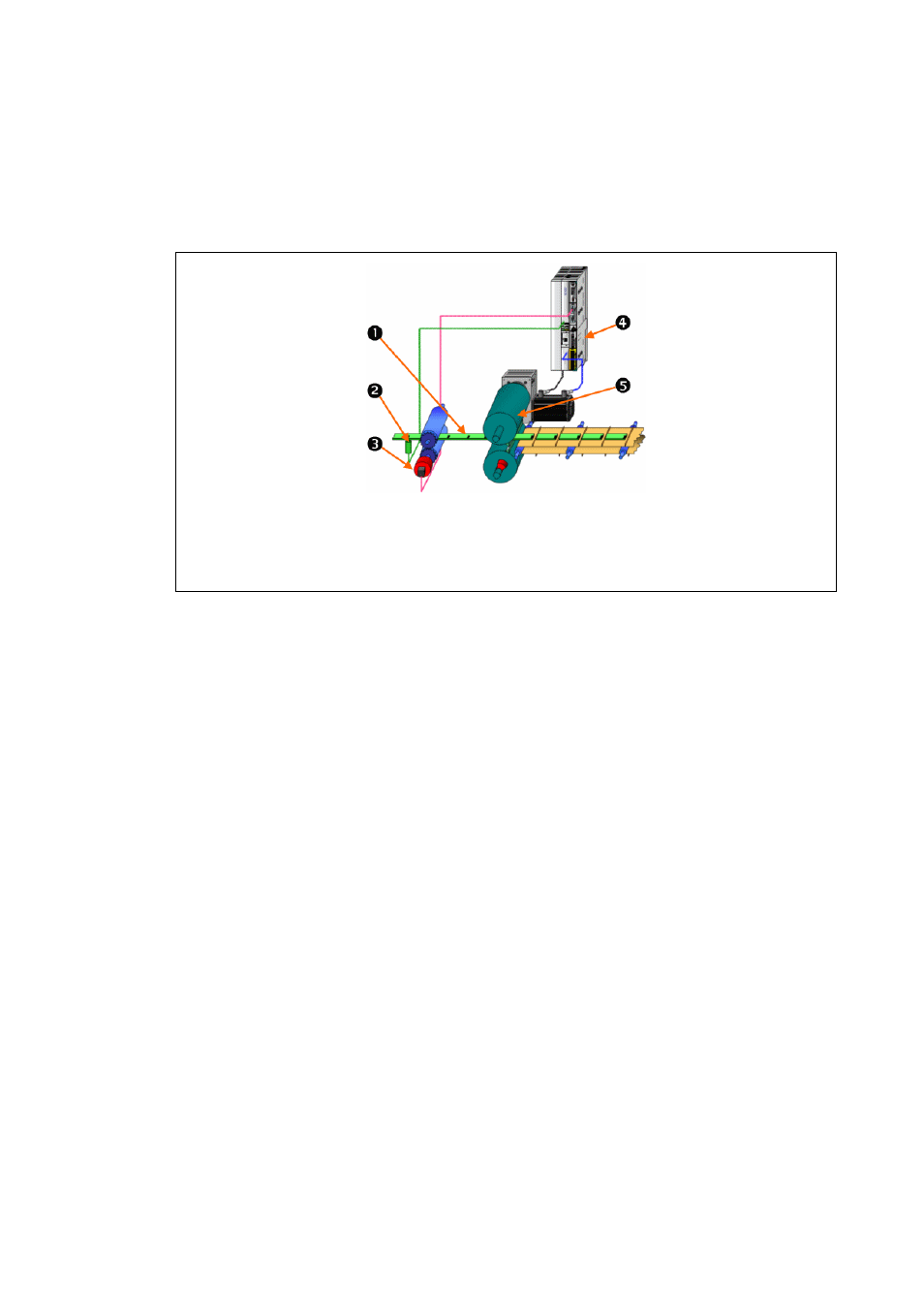

[8-10] Principle: mark-controlled synchronisation of the tool to the material

• The master speed is either taken from the material path via an encoder or is stipulated in

advance by the drive that determines the speed (virtual master).

• The tools rotate and are therefore modulo with a fixed modulo cycle.

• The material is modulo with a variable cycle (is measured if necessary, e.g. in the case of foil).

• The curves are created for a nominal cycle/register.

• Adaptation to the measured cycle is carried out individually for each tool in the drive by

means of its own sensors during the runtime.

Mark track on the material

Mark sensor for detecting the register on the material (touch probe evaluation within the controller)

Master value encoder (TTL incremental encoder; supplies speed by means of digital frequency input)

Controller with electronic cam technology

Orientation of the tool to the material (here: to the cutting mark)