IAI America ERC3 User Manual

Page 86

Chapter 2 Installation

2.3 How to Install

76

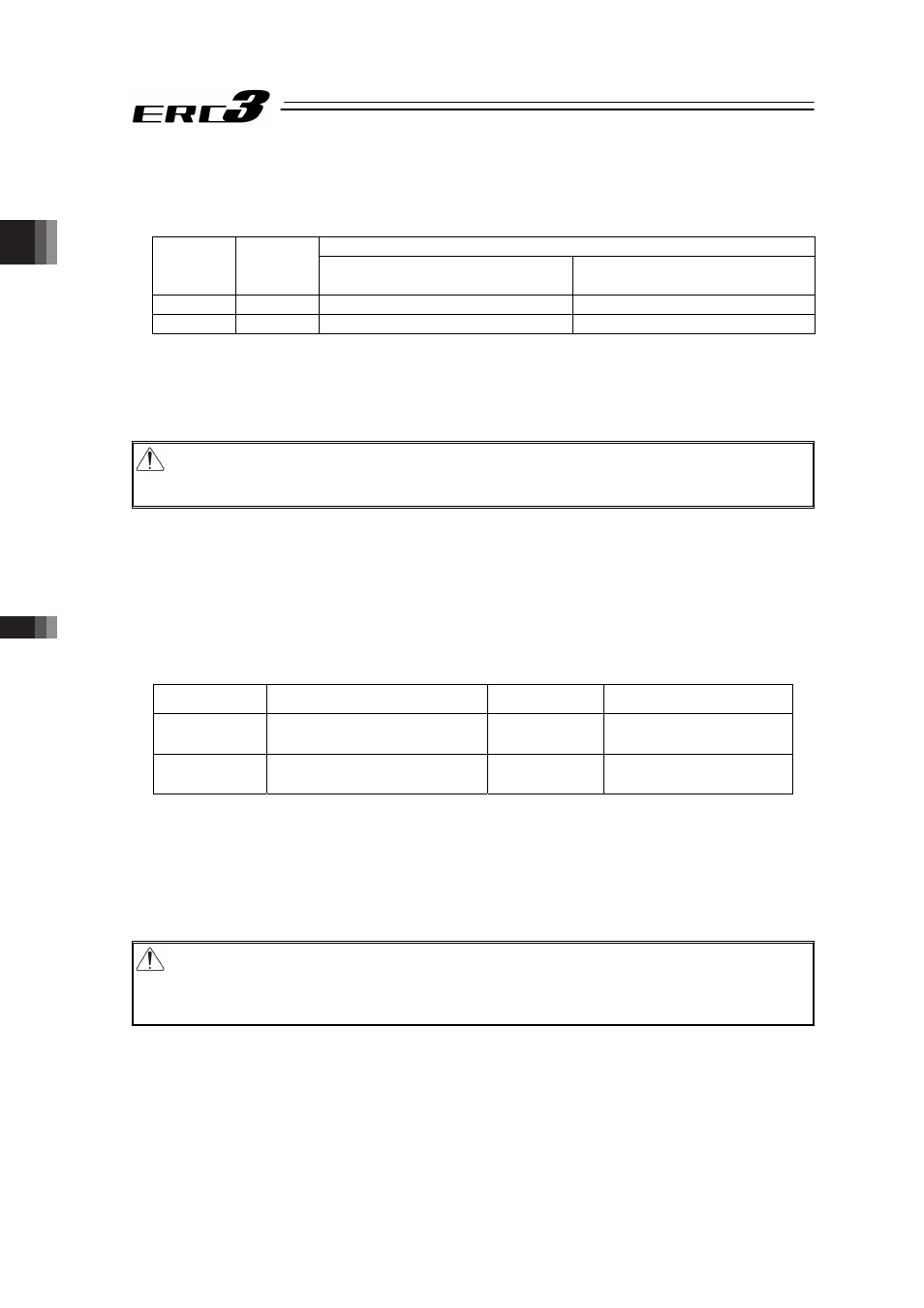

(2) Mounting Method 1 (When utilizing tapped holes)

Follow the table below for the torque to tighten the attachment screws.

Tightening Torque [N•m]

Actuator

Type

Tapping

Diameter In the case that steel is used for the

bolt seating surface:

In the case that aluminum is used

for the bolt seating surface:

SA5C

M4

3.59

1.76

SA7C

M5

7.27

3.42

Regarding attachment screws

• It is recommended to use high-tensile bolts with ISO-10.9 or more.

• The length of thread engagement should be 1.8 times more than the nominal diameter, and

pay attention not to stick the screw out inside the actuator.

Caution: Pay attention to the bolt length. If a bolt with inappropriate length is used, it may

cause an abnormality or drop in the accuracy on the driving part, damage on tapped

holes or accident or failure due to insufficient strength on the actuator attachment.

(3) Mounting Method 2 (When using through holes)

Detach the screw cover and install with hex socket head cap screws from inside the actuator.

Do not lose the screws for the screw cover attachment.

Be careful not to make a dent or scratch on the ball screw by dropping a screw or tool on it.

After installation is finished, put the screw cover back on.

Attach the actuator with the hex socket head cap screw described in the table and with the

specified tightening torque.

Regarding attachment screws

• It is recommended to use high-tensile bolts with ISO-10.9 or more.

• For the effective engagement length between the bolt and female thread, provide at least the

applicable value specified below:

Female thread is made of steel material ψ Same length as the nominal diameter

Female thread is made of aluminum ψ 1.8 times of nominal diameter

Caution: Pay attention when selecting screws. If a bolt out of the instruction is used, it may

cause an abnormality or drop in the accuracy on the driving part, damage on tapped

holes or unexpected accident or failure due to insufficient strength on the actuator

attachment or interference on the driving area.

Actuator Type

Mounting Holes

Mounting Screw Tightening Torque [N•m]

SA5C

I

4.5 through hole

I

8 counter boring depth 4.5

M4

1.76

SA7C

I

6 through hole

I

9.5 counter boring depth 5.5

M5

3.42