4 handling of e-con connector (how to connect) – IAI America ERC3 User Manual

Page 403

Chapter 10

Appendix

10.2 W

ay to Set Multiple Controllers with 1

Teaching

Tool

393

Wire

Wire

Clamp Lever

Pin No.

Press

welding

Press

welding

Press

welding

Press

welding

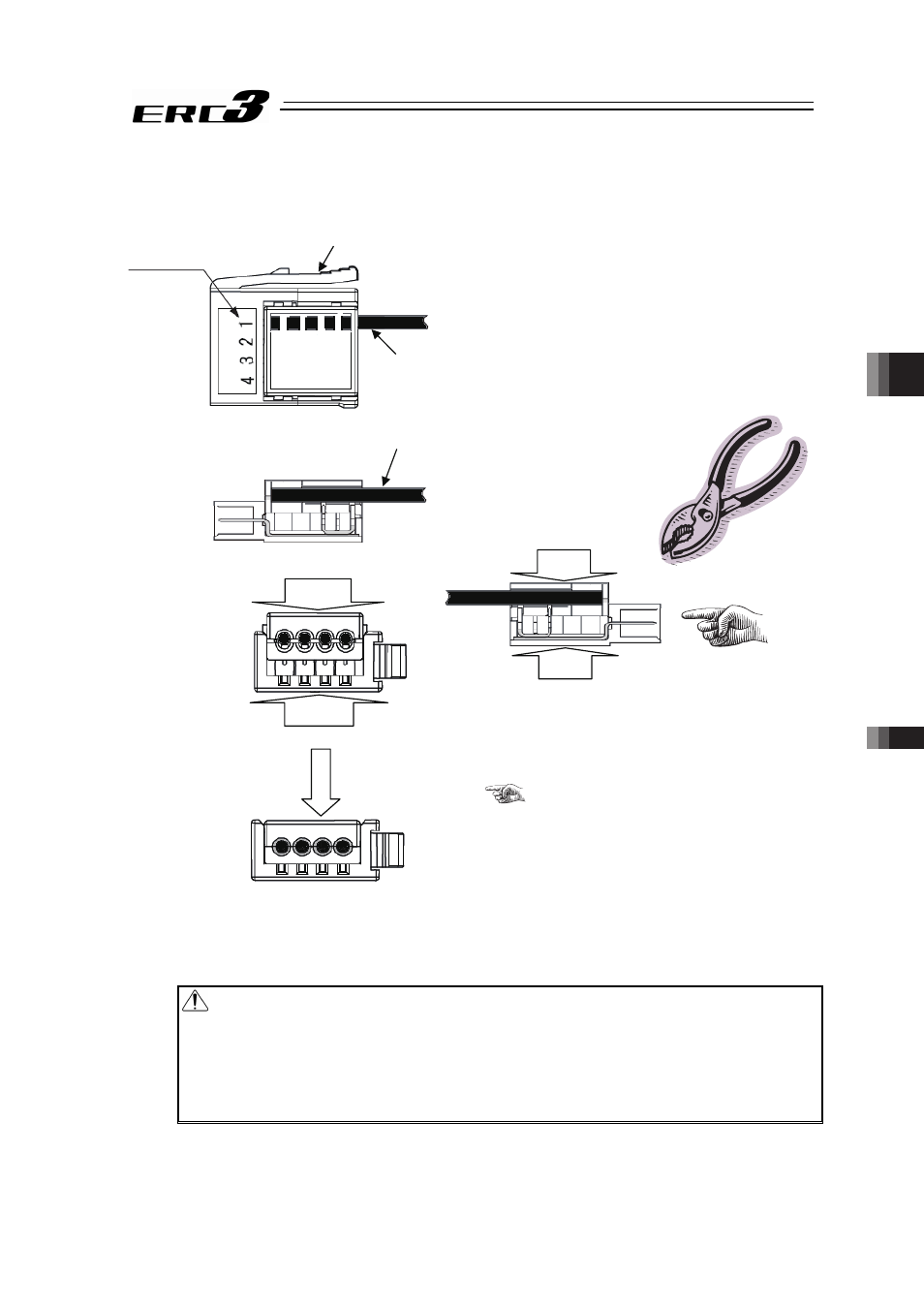

10.2.4 Handling of e-CON connector (how to connect)

1) Check the applicable cable size.

Check the applicable cable. If it is not applicable,

it may cause a connection failure or a breakage

of the connector.

2) Check the pin numbers, do not reveal the

sheath, and insert the cable till it reaches the

end.

Revealing the sheath may cause a failure such

as short circuit or cable fall out.

3) Use a (generally purposed) parallel plier with

the width of 10mm or more to press-weld the

cable from top and bottom.

Use the parallel plier from the direction of

, grip it while checking the condition of

press-welding to make sure the press is in right

angle and press it until it becomes completely

flat to the housing.

If the inserting is not enough, it may not be able

to attach to the socket or may cause a contact

failure.

4) After finishing the press-welding, pull the cable

lightly to confirm that won’t come out.

Caution :

1) e-CON connector cannot be reused once the press-welding is failed. Use a new

connector to retry the press-welding.

2) When connecting to the socket, hold the connector with care not to touch the clamp lever,

insert the connector in parallel to the socket until the clamp lever makes a “click” sound.

3) After joining to the socket, do not pull the cables or pull the connector without releasing

the lock of the clamp lever.