2 installation of slider type, 1] attachment of actuator body – IAI America ERC3 User Manual

Page 84

Chapter 2 Installation

2.3 How to Install

74

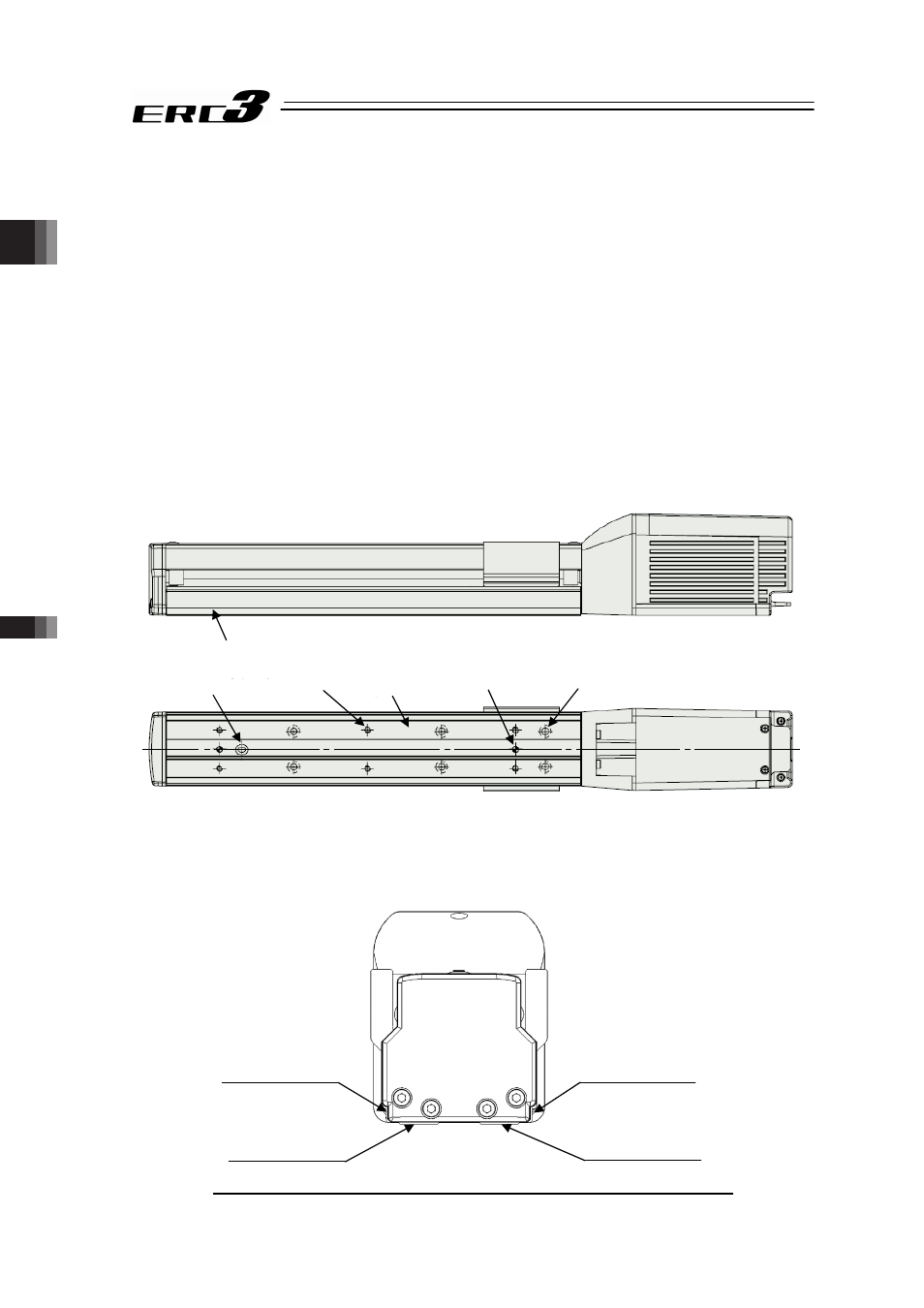

2.3.2 Installation of Slider Type

䎃

[1] Attachment of Actuator Body

The attachment surface should be a machined surface or a flat surface that possesses an

equivalent accuracy, and the flatness should be 0.05mm or less. Also, the platform should have

a structure stiff enough to install the unit so it would not generate vibration or other abnormality.

Also consider enough space necessary for maintenance work such as actuator replacement

and inspection.

There are datum surfaces for attachment on the base.

The flatness of the slider movement is designed to be 0.05mm/m at maximum to the datum

surface.

On the rear side of the actuator, there are tapped holes and through holes for attachment and

reamed hole and oblong hole for positioning. See the appearance drawings for the details of the

position and diameters. [Refer to Chapter 9]

Utilize the reamed holes when repeatability in the attachment after detaching is required.

However, when small tunings such as the perpendicularity is required, consider such things like

to use one reamed hole.

(1) Datum Surface

There are datum surfaces for attachment on the base.

䎃

Positions of Datum Surfaces (View from shaft end of opposite side of motor)

Datum Surface

Datum Surface

Through Hole

Reamed Hole

Tapped

Hole

Oblong Hole

Datum

Surface

Datum Surface

Datum Surface

Datum Surface