IAI America ERC3 User Manual

Page 394

Chapter 8

Actuator Maintenance Check

8.7 Motor Replacement Process

384

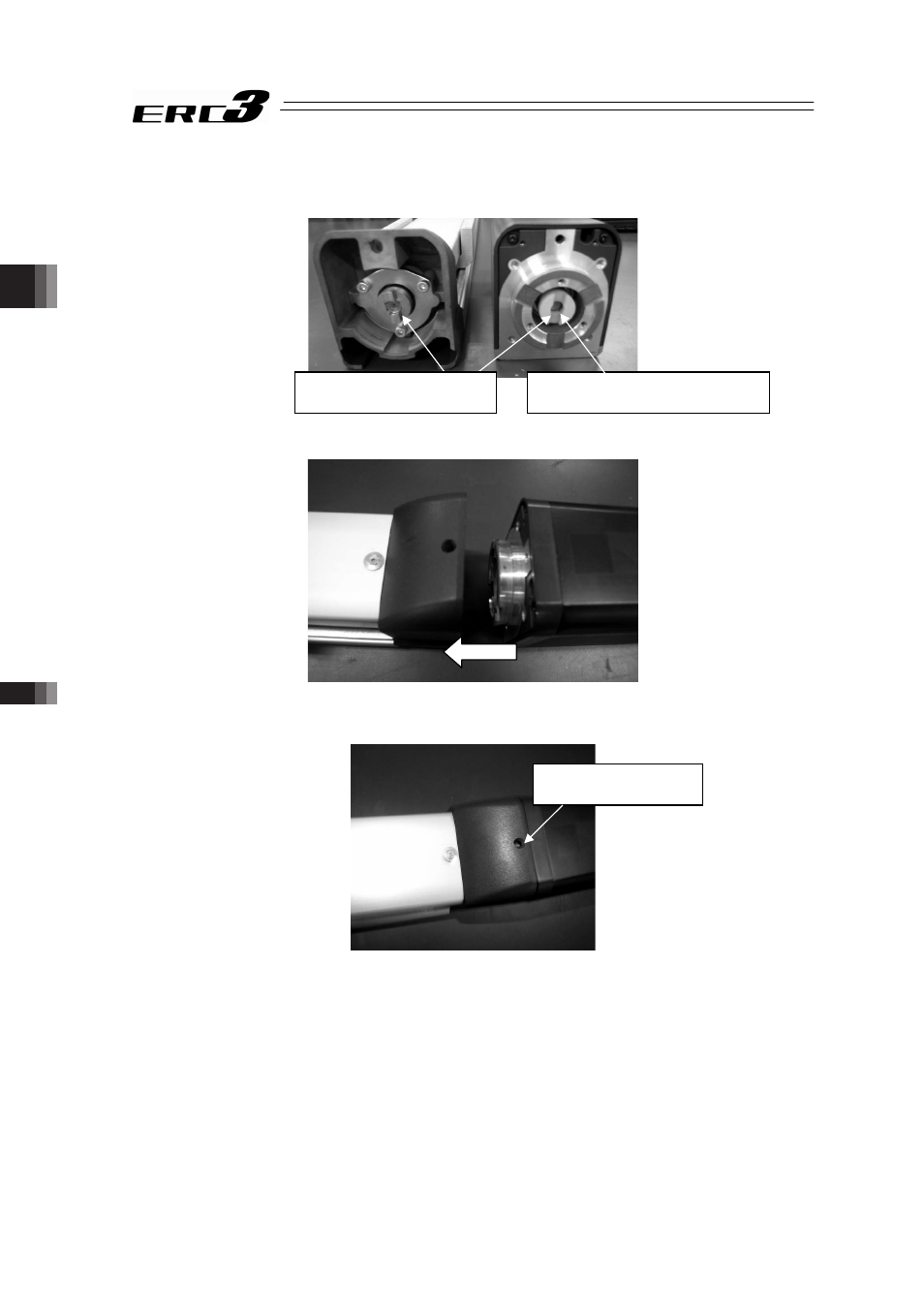

3) Make the profiles on the actuator side and motor unit side aligned so the projection matches to

the slit.

4) Attach the motor unit for replacement with the projection being matched with the slit.

5) Tighten the screw to affix the motor unit to the actuator with 2.5mm hex wrench.

Apply grease to the coupling part.

TL101Y grease made by NOK

Make the projection and slit

matched with each other.

Screw to attach the

Actuator and Motor Unit

See also other documents in the category IAI America Hardware:

- ERC2 (138 pages)

- ERC2 (188 pages)

- ERC (153 pages)

- RCA-E (53 pages)

- RCA-P (42 pages)

- RCB-101-MW (38 pages)

- RCP2-C (178 pages)

- RCS-E (102 pages)

- RCA-A4R (72 pages)

- RCA-RA3C (114 pages)

- RCA-SRA4R (56 pages)

- RCA2-RA2AC (100 pages)

- RCA2-SA2AC (92 pages)

- RCA2-TA4C (134 pages)

- RCD-RA1D (40 pages)

- RCP2-BA6 (72 pages)

- RCP2-GRSS (130 pages)

- RCP2-HS8C (126 pages)

- RCP2-RA2C (120 pages)

- RCP2-RTBS (80 pages)

- RCP2W-SA16C (46 pages)

- RCP3-RA2AC (60 pages)

- RCP4-RA5C (82 pages)

- RCP4-SA5C (94 pages)

- RCP4W (96 pages)

- RCS2-F5D (142 pages)

- RCS2-GR8 (46 pages)

- RCS2-RN5N (80 pages)

- RCS2-RT6 (60 pages)

- RCS2-SA4C (258 pages)

- RCS2-TCA5N (62 pages)

- RCL-SA1L (66 pages)

- RCL-RA1L (56 pages)

- RCLE-GR5L (46 pages)

- IK Series (16 pages)

- FS (84 pages)

- IF (76 pages)

- ISB (114 pages)

- ISDA (126 pages)

- ISDB (116 pages)

- ISPWA (90 pages)

- NS (78 pages)

- ICS(P)A (16 pages)

- RS (46 pages)